01

High-Elasticity Tensioned Polyurethane Screen

High - quality, highly wear - resistant polyurethane material

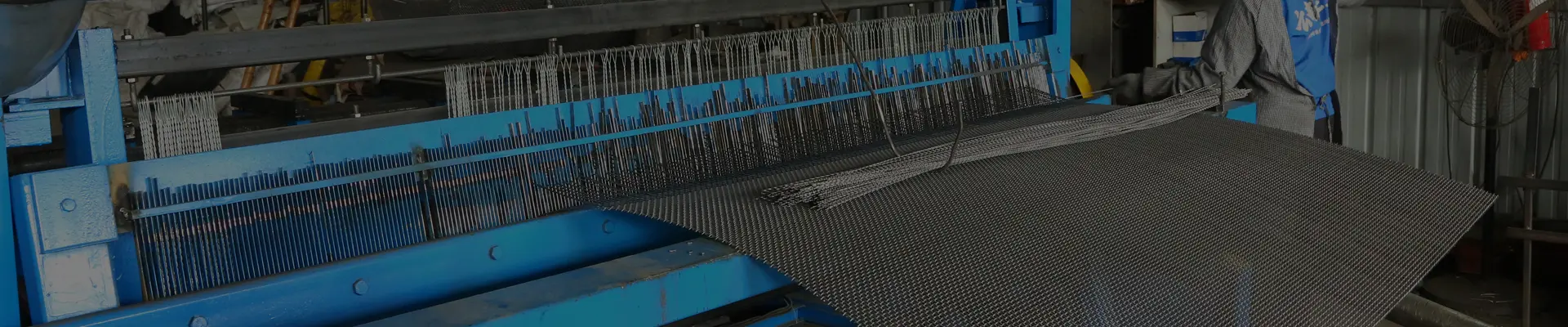

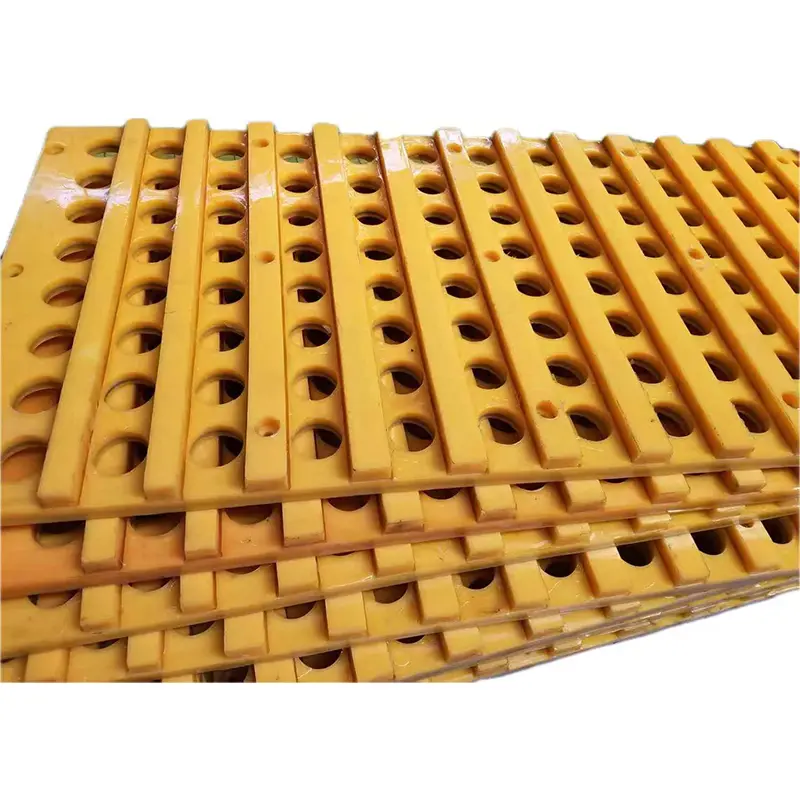

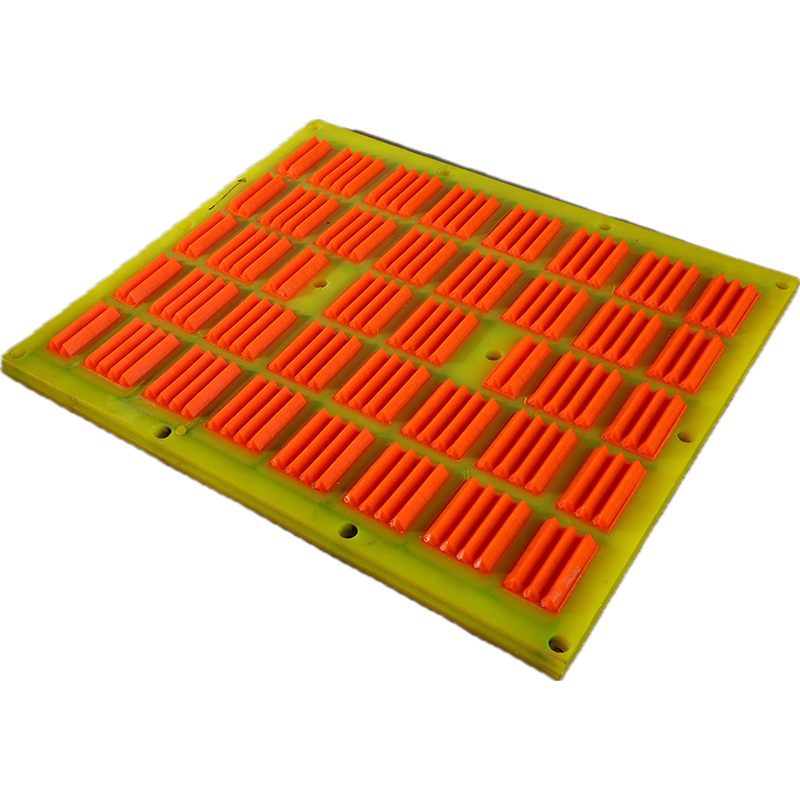

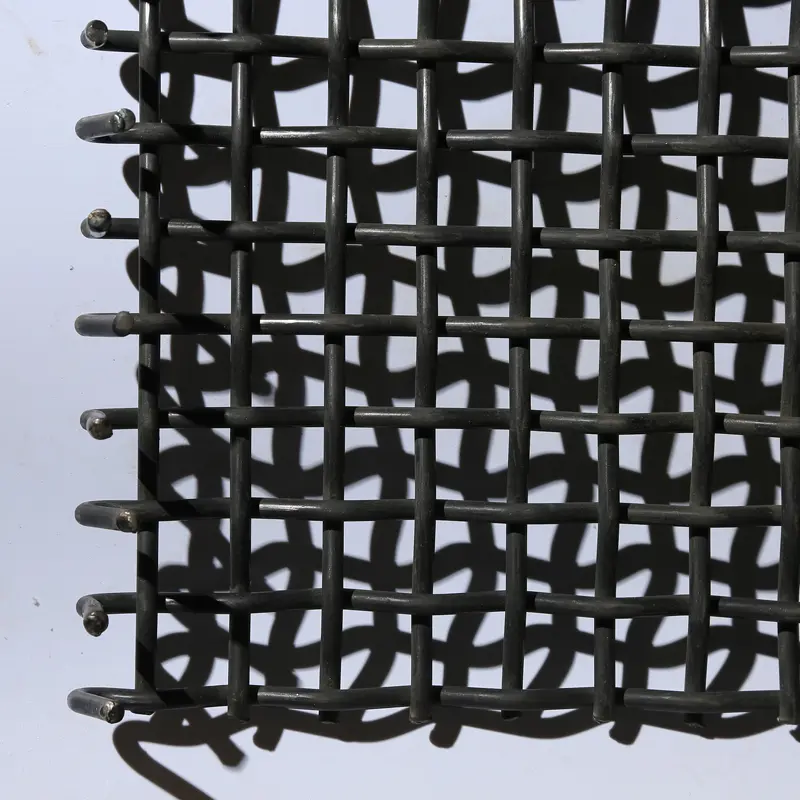

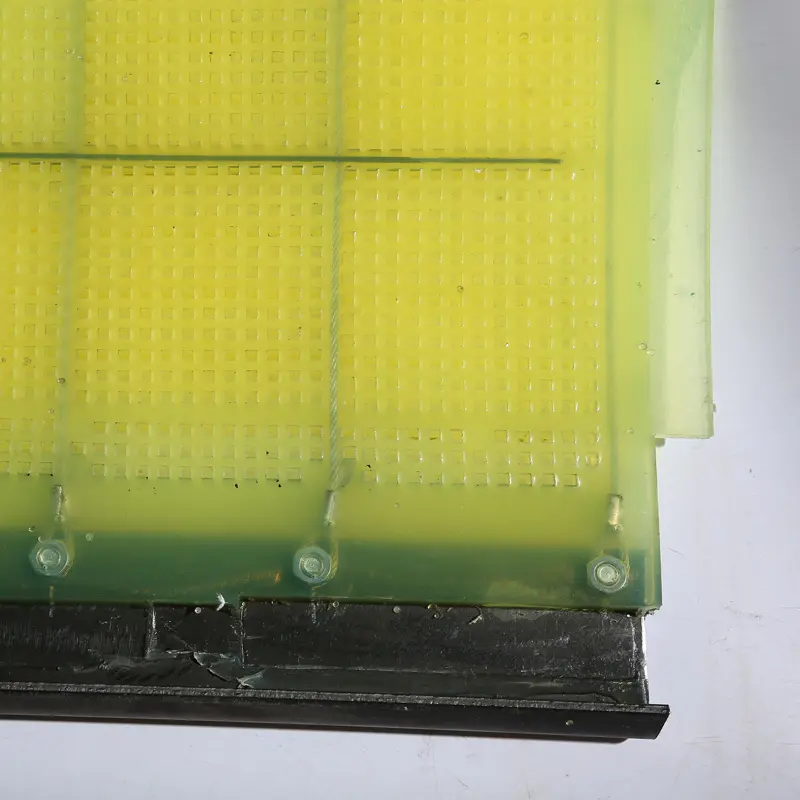

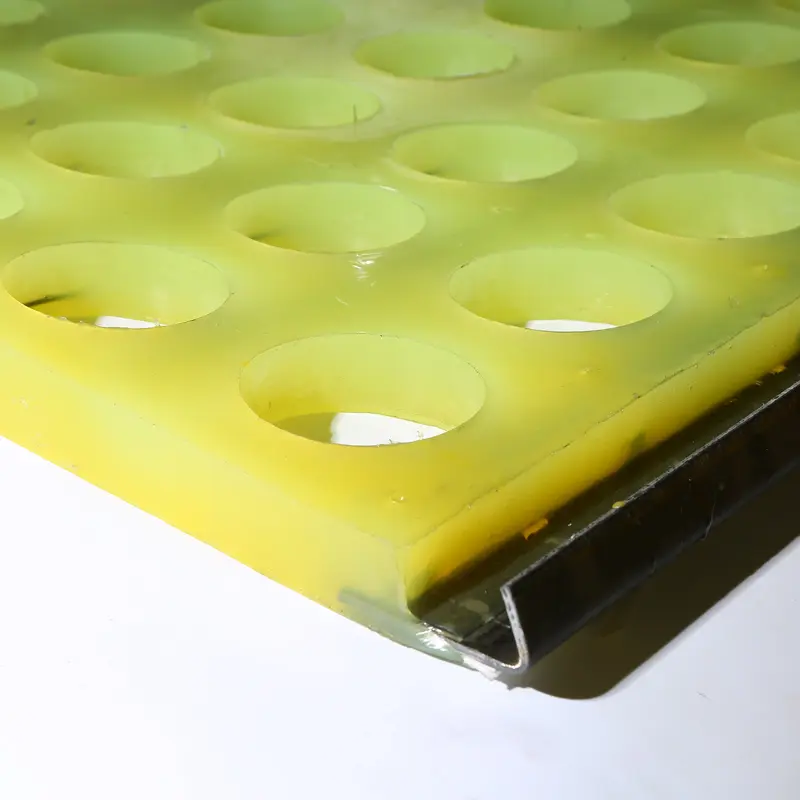

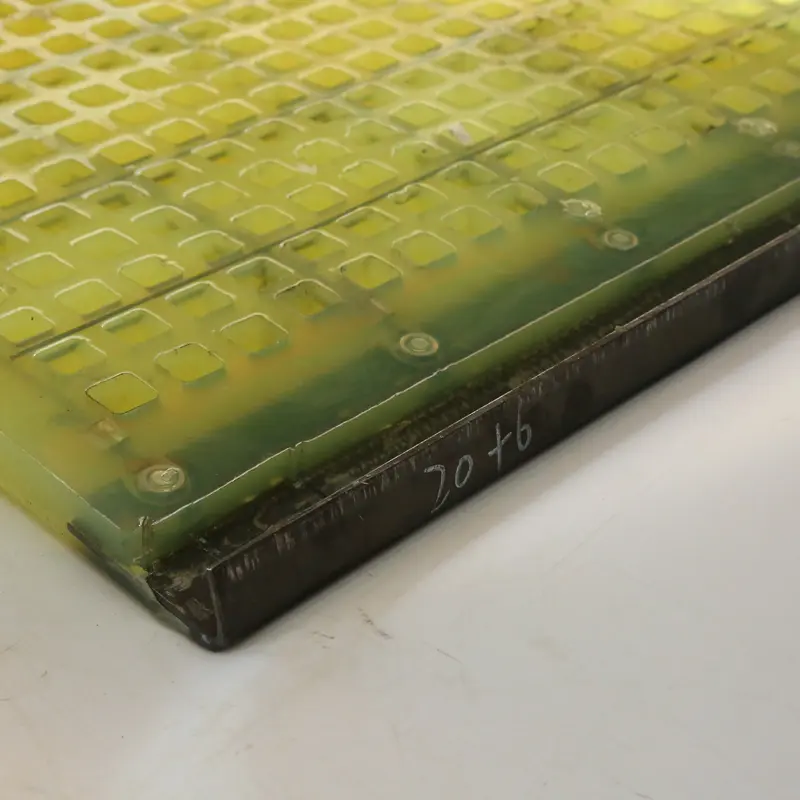

The design of the polyurethane hook plate is extremely ingenious. Both its longitudinal and transverse bars are made of high - quality, highly wear - resistant polyurethane material. This polyurethane material has been processed through special techniques, endowing it with extraordinary wear resistance. It can effectively withstand the frequent friction and impact of materials during long - term and high - intensity screening operations, greatly extending the service life of the hook plate. More crucially, high - strength steel wires are evenly embedded inside the longitudinal and transverse bars. These steel wires are like a sturdy skeleton, providing powerful support for the polyurethane bars. This enables the bars to maintain a stable shape and structure even when under immense pressure, making them less likely to deform or break. Thus, it comprehensively ensures the reliable operation of the polyurethane hook plate under complex working conditions.

unique and distinctive structure

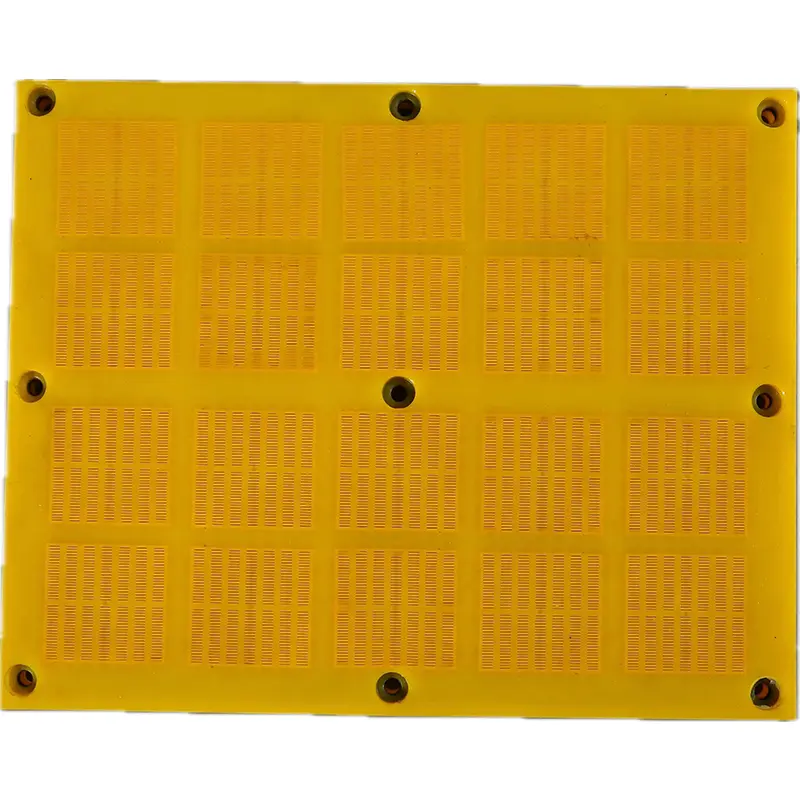

The polyurethane hook plate has a unique and distinctive structure. This structure imparts it with appropriate elastic and plastic forces, and this characteristic plays a vital role in the screening process. On the one hand, the right amount of elasticity allows the screen bars to deform just right when materials pass through, cleverly preventing materials from getting stuck between the screen holes and significantly reducing the occurrence of clogging. On the other hand, the plastic force of the screen bars, combined with its unique structural design, triggers high - frequency vibrations of the second harmonic. These high - frequency vibrations generate a special force that makes it difficult for sticky materials to adhere to the screen bars, thereby effectively reducing sticky blockages. In addition, the hook plate has an extremely high practical open - area ratio, which means that more materials can pass through per unit area. Coupled with its excellent anti - clogging performance, it ultimately achieves a substantial increase in screening efficiency. Whether handling fine materials or coarse - grained materials, it can exhibit excellent screening results and is widely applicable to various industrial production scenarios with high requirements for screening accuracy and efficiency.

convenience in actual use

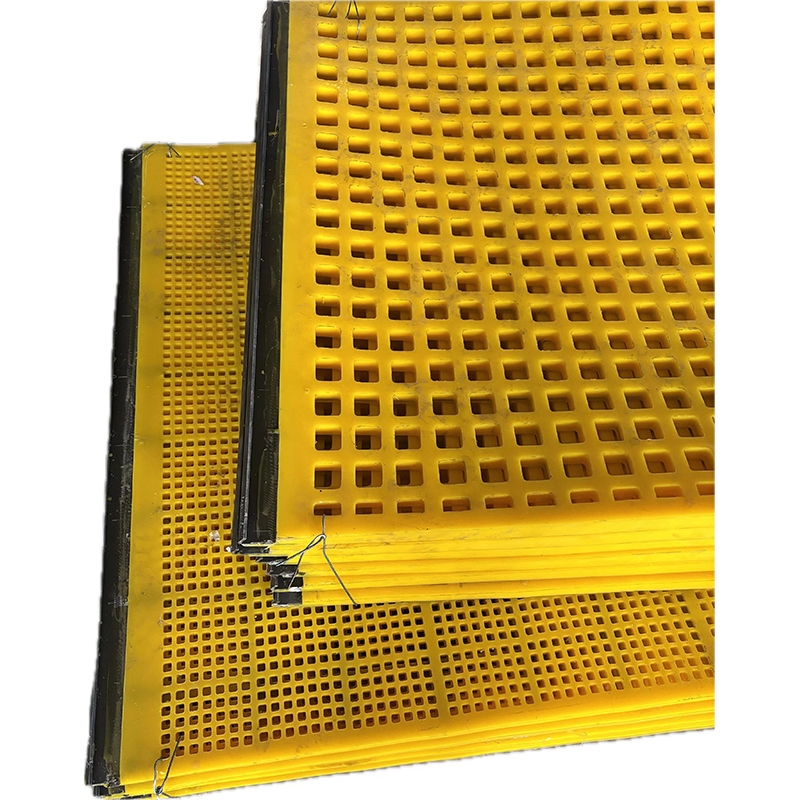

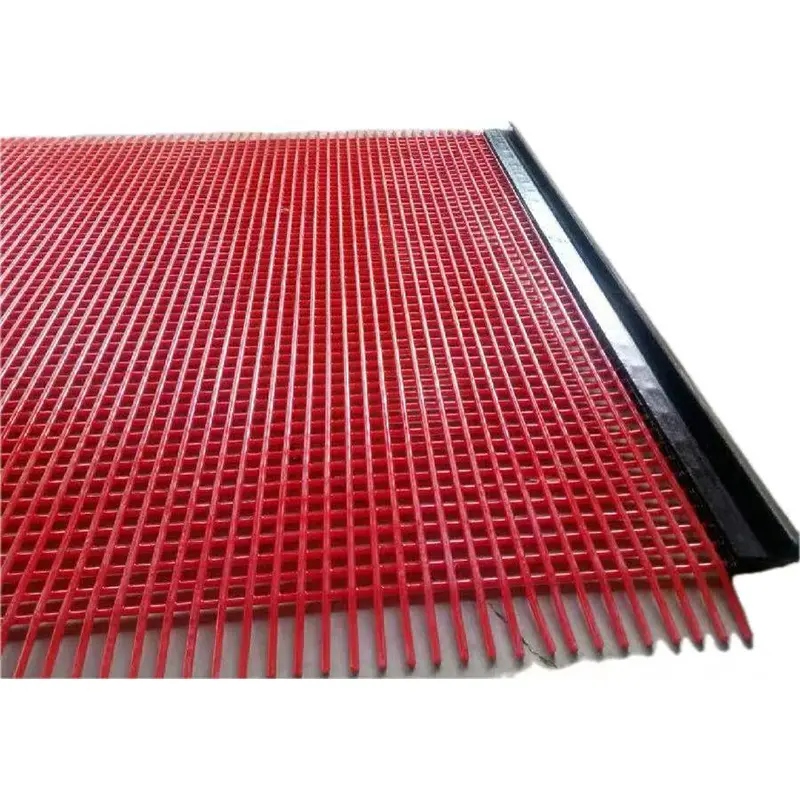

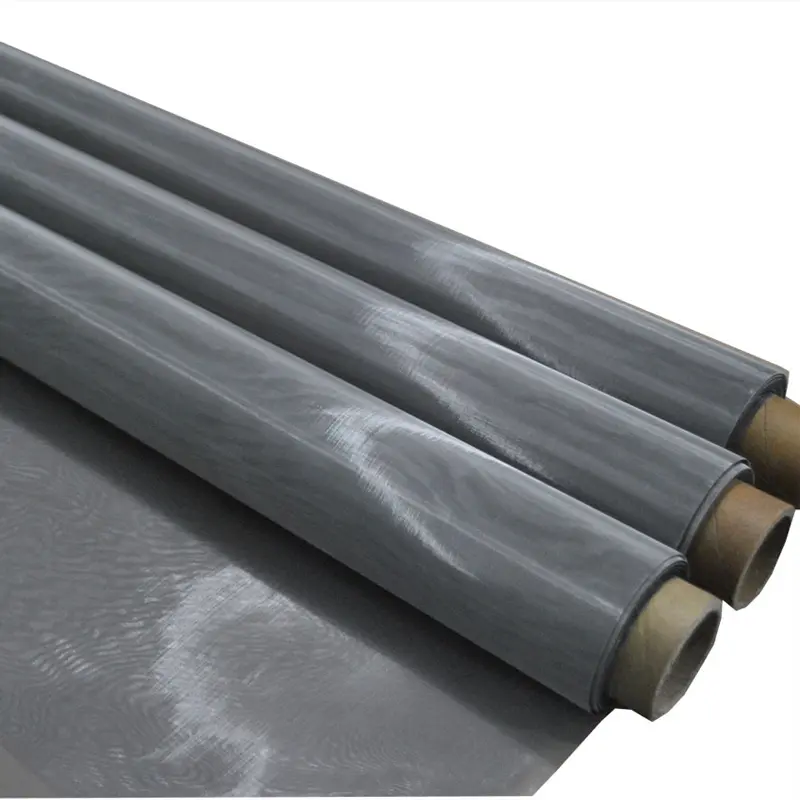

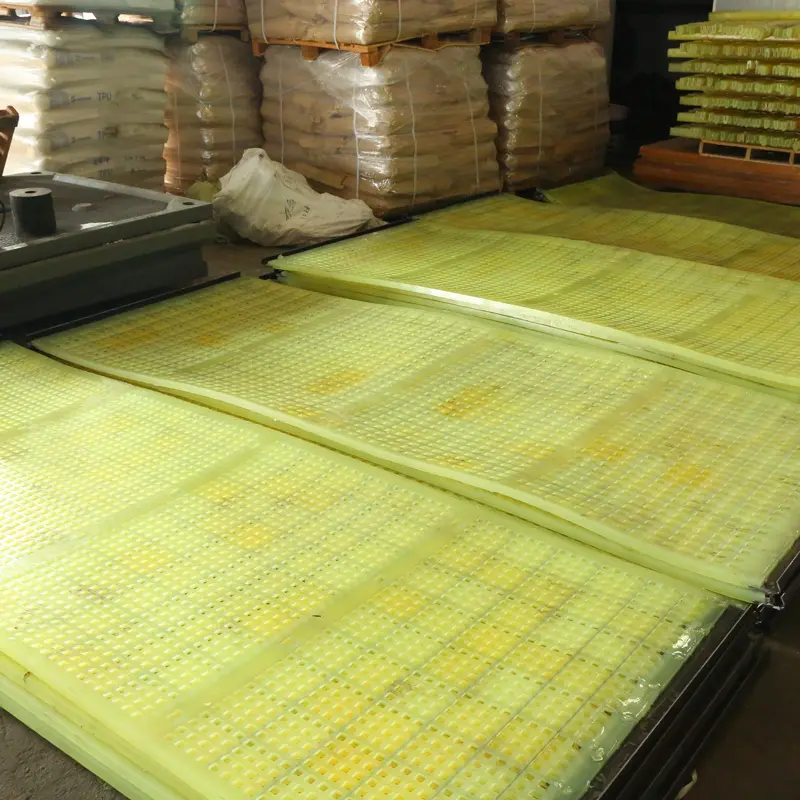

The design of the polyurethane screen fully takes into account the convenience in actual use. Elastic tension hooks are carefully installed on both sides of the screen. These elastic tension hooks can not only ensure that the screen remains taut at all times after installation, guaranteeing the stability and accuracy of the screening operation, but also make the installation and disassembly process of the screen easy and convenient due to their elastic design. Staff can quickly complete the replacement of the screen through simple operations, greatly saving maintenance time and labor costs. Overall, the polyurethane screen has the remarkable advantage of being lightweight. This means that during transportation, there is no need to rely on large - scale and heavy - duty transportation equipment, reducing transportation difficulties and costs. At the same time, its good flexibility allows the screen to be flexibly folded or curled during storage, taking up minimal space and facilitating warehousing management. Whether in daily production operations or in the maintenance and transportation of equipment, the polyurethane screen, with its unique design and excellent performance, brings great convenience to users.

excellent noise - reduction and shock - absorption performance

The polyurethane screen demonstrates excellent noise - reduction and shock - absorption performance in practical applications. Due to the good elastic and damping properties of the polyurethane material itself, when materials impact the screen at high speed, the screen can effectively absorb the impact energy like an efficient cushion, converting the impact force into its own elastic deformation energy. This greatly reduces the impact force of materials on the screen and equipment. This excellent impact - absorption ability not only helps to extend the service life of the screen and equipment but also significantly reduces the noise generated by material impacts. In an industrial production environment, noise is often a non - negligible issue. Excessive noise not only poses a hazard to the health of workers but also may affect production efficiency and work quality. The application of the polyurethane screen can effectively reduce the noise level in the work area, creating a relatively quiet and comfortable working environment for workers, which meets the requirements of modern industry for environmental protection and human - oriented production.

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)