01

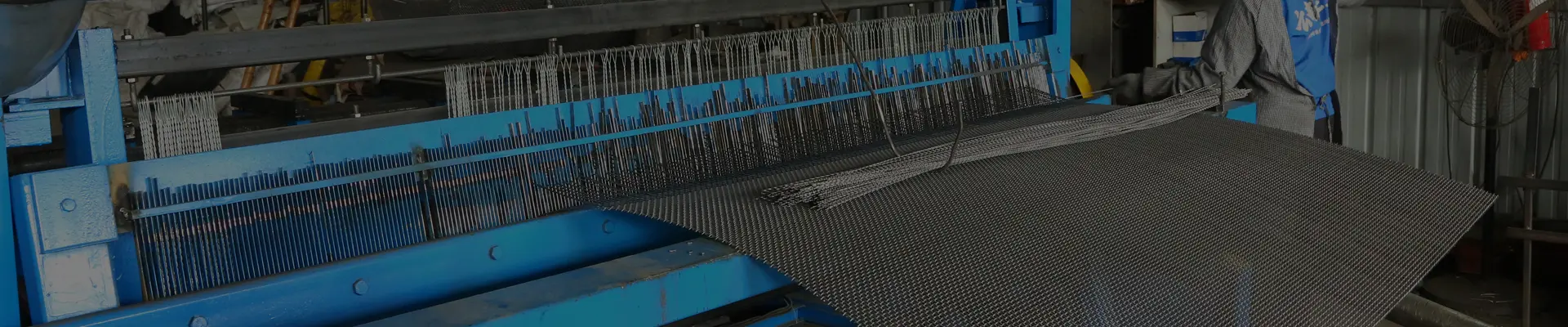

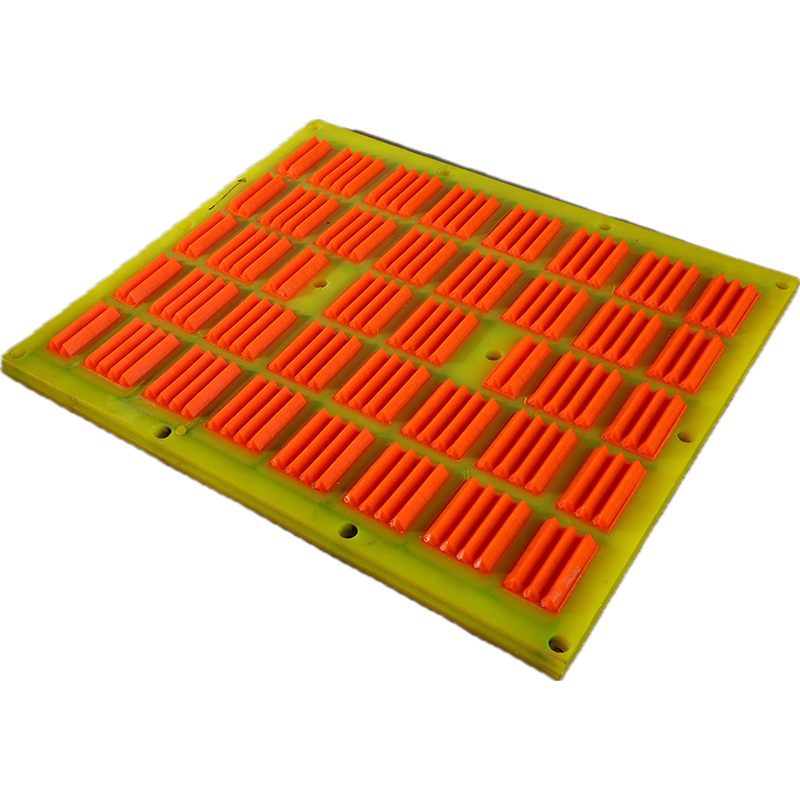

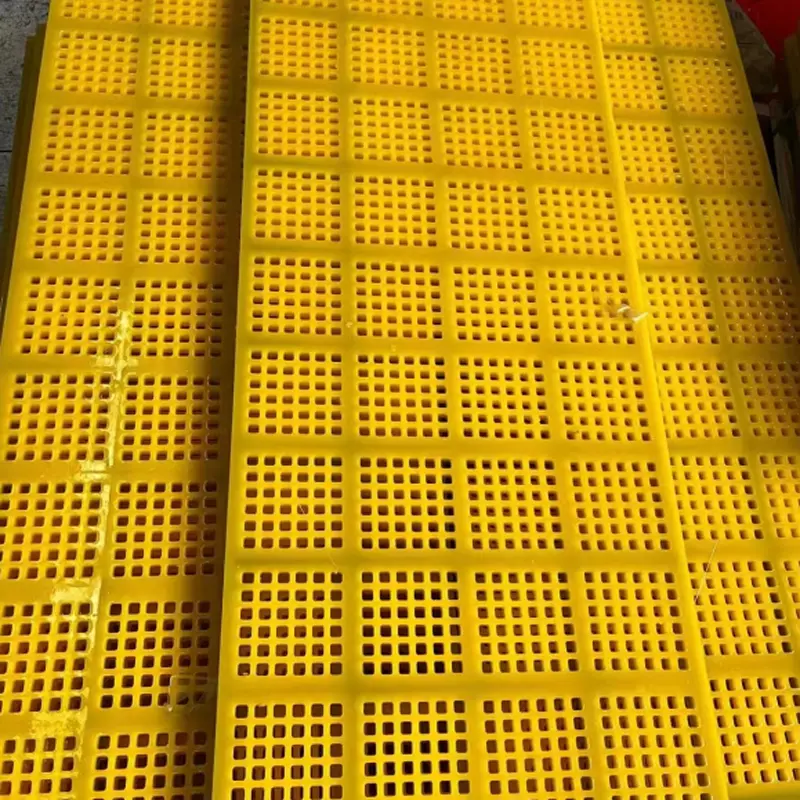

Skeleton - Type Polyurethane Screen

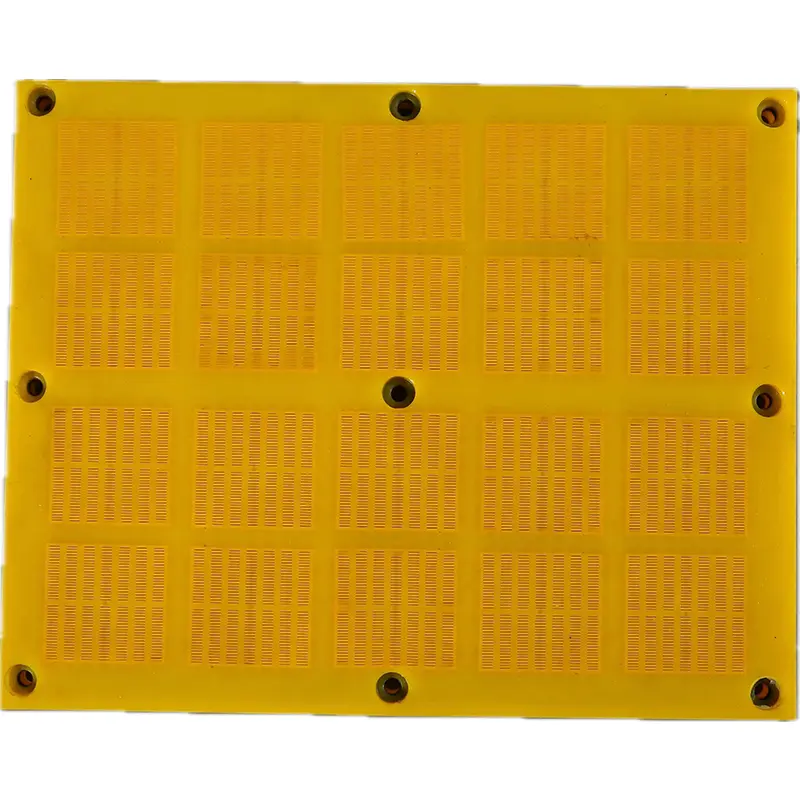

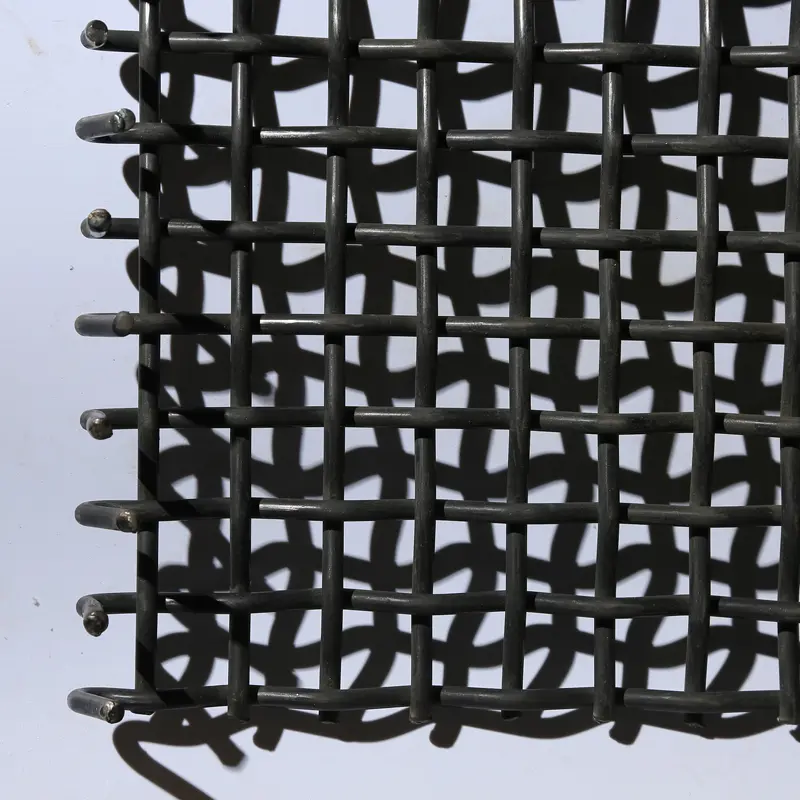

impact area

★ In the impact area, it is specifically set in the form of blind holes, and this part is thickened. Since the impact area will be frequently hit by high - speed materials during the working process, an ordinary structure is difficult to withstand such high - intensity impacts. The blind - hole design can buffer the impact force of the materials, reducing the direct damage to the surface of the screen, and the thickening treatment further enhances the impact - resistance of this area. As a result, when facing the continuous impact of a large amount of materials, the screen can maintain its structural integrity, effectively reducing the risk of damage, thus ensuring the stable operation of the equipment and efficient screening operations.

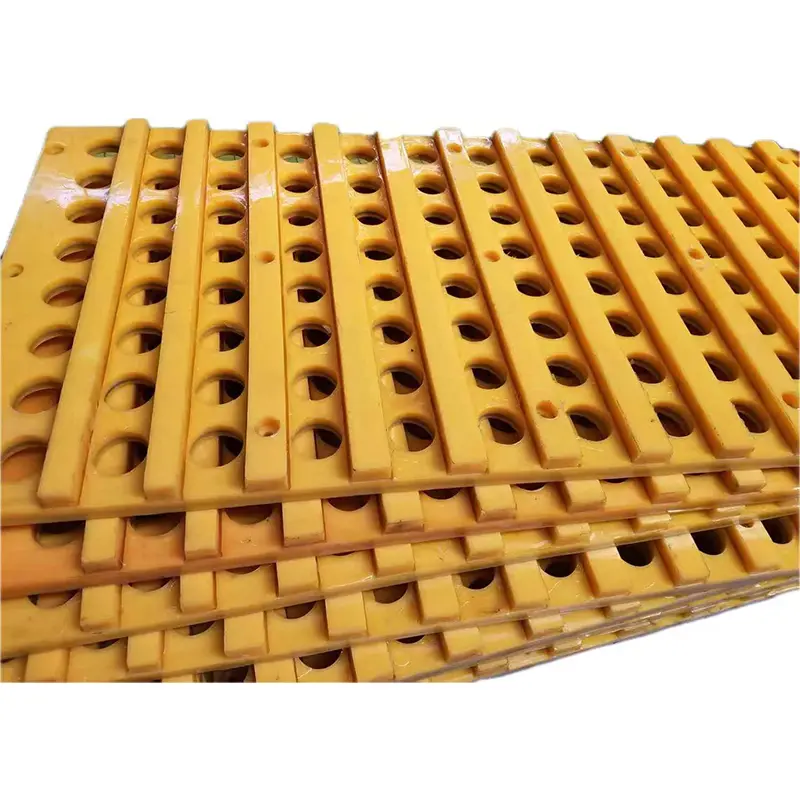

equipped with stiffeners

★ The screen is specially equipped with stiffeners, and these stiffeners are distributed at key positions of the screen. They are like the "skeleton" of the screen, playing a crucial supporting role. When the screen is under load, the stiffeners can evenly disperse the pressure, ensuring that the screen is precisely tensioned in all directions. This precise tensioning not only guarantees the flatness of the screen, enabling it to be evenly stressed during the screening process, but also effectively prevents the screen from deforming due to uneven stress. Whether facing long - term continuous work or high - load screening tasks, the stiffeners can keep the screen in good working condition at all times, maintaining stable and efficient screening performance.

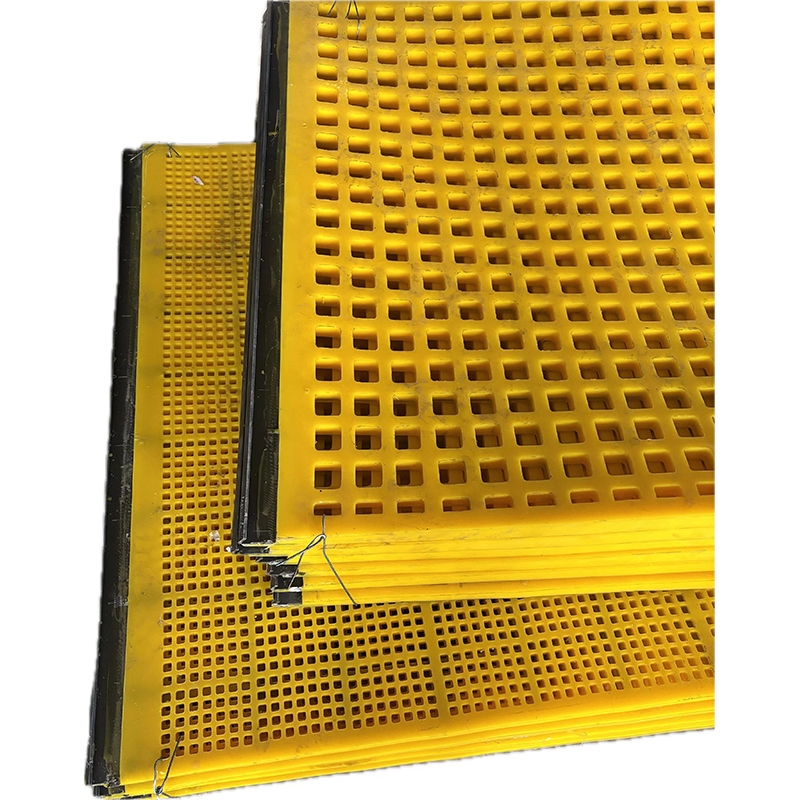

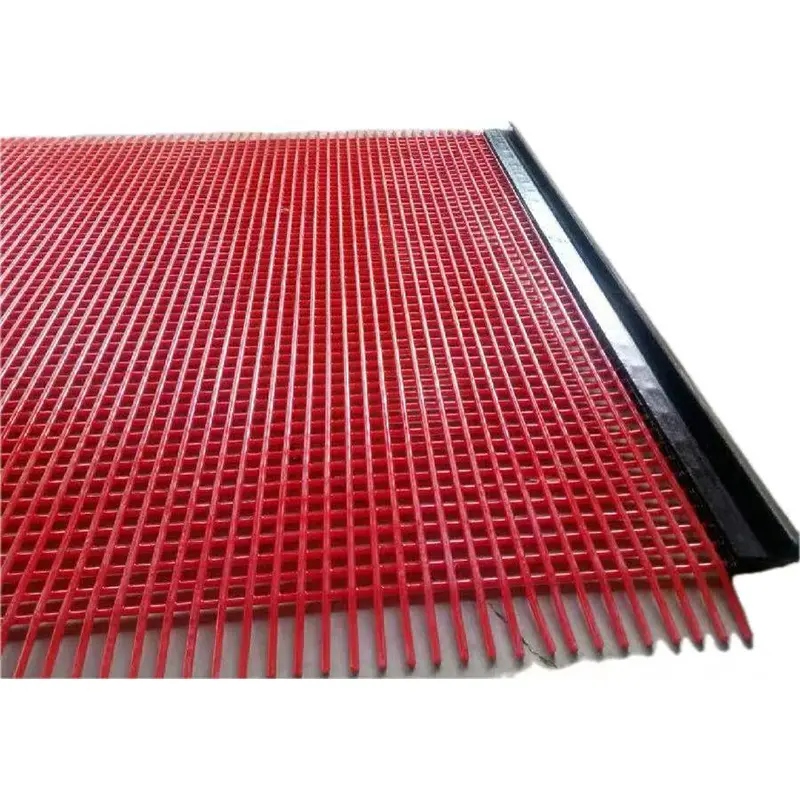

undergone fine processing and reinforcement treatment

★ The edges of the screen have undergone fine processing and reinforcement treatment. During the processing, strict control is exerted on the flatness and smoothness of the edges to ensure the consistency of the edges. The reinforcement treatment further improves the strength and toughness of the edges. With such carefully processed screen edges, a perfect sealing effect can be achieved when splicing or installing with other screens. On the one hand, it effectively prevents materials from leaking from the edges of the screen, ensuring the accuracy and integrity of screening; on the other hand, the good sealing performance also helps to reduce noise generation, creating a relatively quiet working environment.

appropriate positions

★ At appropriate positions, stud holes are cast, and the positions of these stud holes have been precisely calculated and designed. By setting stud holes at these specific positions, it can be ensured that when installing the screen, the screen can be accurately fixed at the central position using studs. Precise central fixation is of vital importance for the normal operation of the screen. It can ensure that the screen always remains in a balanced state during the working process, avoiding problems such as uneven screening and aggravated local wear caused by deviation. At the same time, stable central fixation also helps to extend the service life of the screen and related equipment, improving the reliability and stability of the entire screening system.

★ The screen holes of the screen adopt a unique conical design. This design has significant advantages. During the screening process, materials enter the screen holes from the large end and gradually move towards the small end as the screening progresses. Due to the structural characteristics of the cone, the movement of materials in the screen holes is smoother, and clogging is less likely to occur. Compared with the traditional screen - hole design, the conical screen holes can allow more materials to pass through the screen in the same time, greatly improving the screening efficiency. Whether dealing with mixed materials with different particle sizes or screening operations with high - precision requirements, the screen with this conical - screen - hole design can demonstrate excellent performance, bringing users a more efficient and high - quality screening experience.

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)