Zhicheng Screen Mesh cooperates with a certain sandstone field in Xichang

A certain sand and gravel yard in Xichang, as an important sand and gravel supplier in the region, has been supplying a large amount of sand and gravel aggregates for various construction projects for a long time. However, with the increasingly stringent building standards, the traditional screening processes have gradually revealed many shortcomings. During the production process, ordinary sieve nets have poor wear resistance. Facing the continuous high-intensity impact and friction of sand and gravel, they are extremely prone to damage and deformation. Frequent replacement of sieve nets not only consumes high labor and material costs but also leads to frequent interruptions of the production line, seriously affecting production efficiency and the timeliness of supply.

In addition, due to the limited precision of the sieve nets, it is difficult to accurately separate sand and gravel of different particle sizes, resulting in frequent problems such as uneven particle size of finished sand and gravel and excessive mud content, which cannot meet the strict requirements of high-end construction projects for high-quality sand and gravel, greatly restricting the competitiveness and business expansion space of the sand and gravel yard in the market.

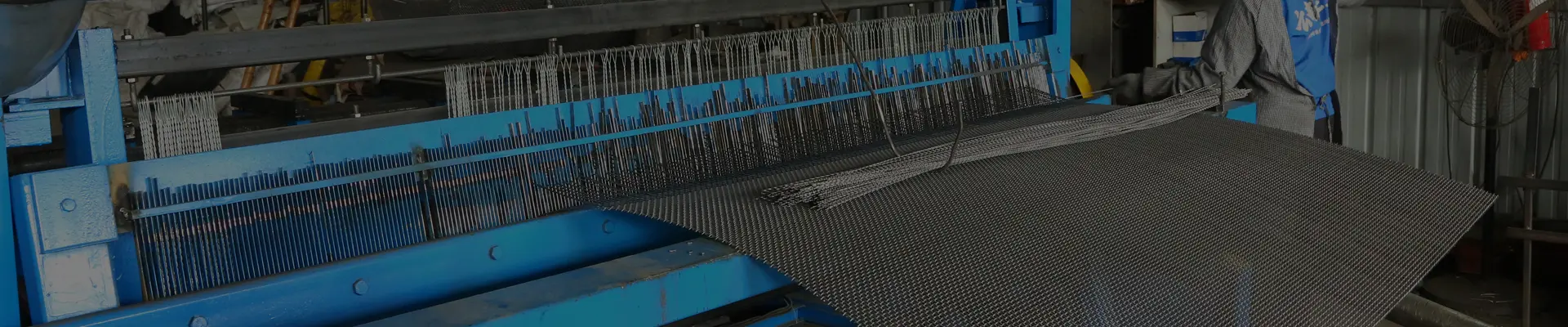

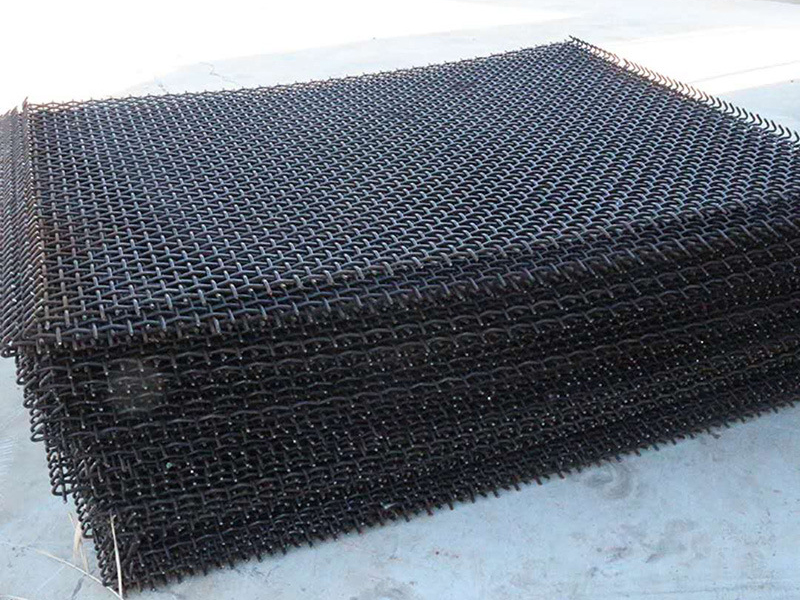

Zhicheng Manganese Steel Sieve Nets stand out among many similar products with their excellent product characteristics. The manganese steel material forged with a special alloy formula endows the sieve nets with super wear resistance, stable structural strength, and excellent impact resistance, bringing a glimmer of hope for solving the screening problems of a certain sand and gravel yard in Xichang. After several rounds of in-depth communication, on-site inspections, and rigorous tests, the two sides firmly joined hands and embarked on a new journey of upgrading the sand and gravel industry.

Zhicheng Manganese Steel Sieve Nets and a certain sand and gravel yard in Xichang have been collaborating closely. Based on the existing crushing and screening equipment and raw material characteristics of the sand and gravel yard, a comprehensive screening solution has been customized. At the beginning of the project, the two sides jointly formed a technical research team and went deep into the front line of sand and gravel production to conduct detailed collection and analysis of key indicators such as the hardness, humidity, and particle size distribution of sand and gravel raw materials. At the same time, they accurately evaluated the production capacity bottlenecks and screening difficulties of each production link.

For example, for the mixed sand and gravel materials after crushing in a certain sand and gravel yard in Xichang, considering that the particle shapes are irregular, the coarse and fine are mixed, and there is a certain amount of sticky soil component, the Zhicheng team carefully designed a multi-level, differentially apertured manganese steel sieve net combination. The uppermost layer adopts a large-aperture, high-strength sieve net to quickly intercept super-large-sized stones and prevent them from causing impact damage to the lower sieve nets; the middle layer sieve net accurately controls the aperture within the range of 2 - 5 mm according to the standard of finished coarse sand, accurately screening out coarse sand that meets the requirements of concrete coarse aggregates; the lower fine sieve net precisely adjusts the aperture to 0.15 - 2 mm to ensure the purity and uniform particle size of fine sand, meeting the strict requirements of fine building construction such as bricklaying and plastering for fine sand. After the implementation of this refined screening solution, the qualification rate of the sand and gravel finished products of a certain sand and gravel yard in Xichang increased by 35% in the first month, and the classification accuracy of different specifications of sand and gravel products reached more than 95%, laying a solid foundation for subsequent precision marketing and expansion of high-end customers.

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)