01

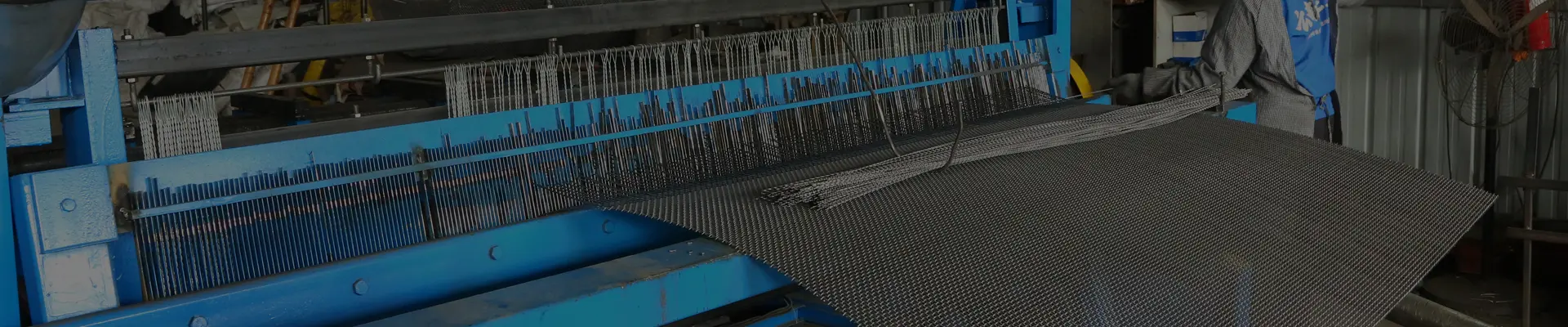

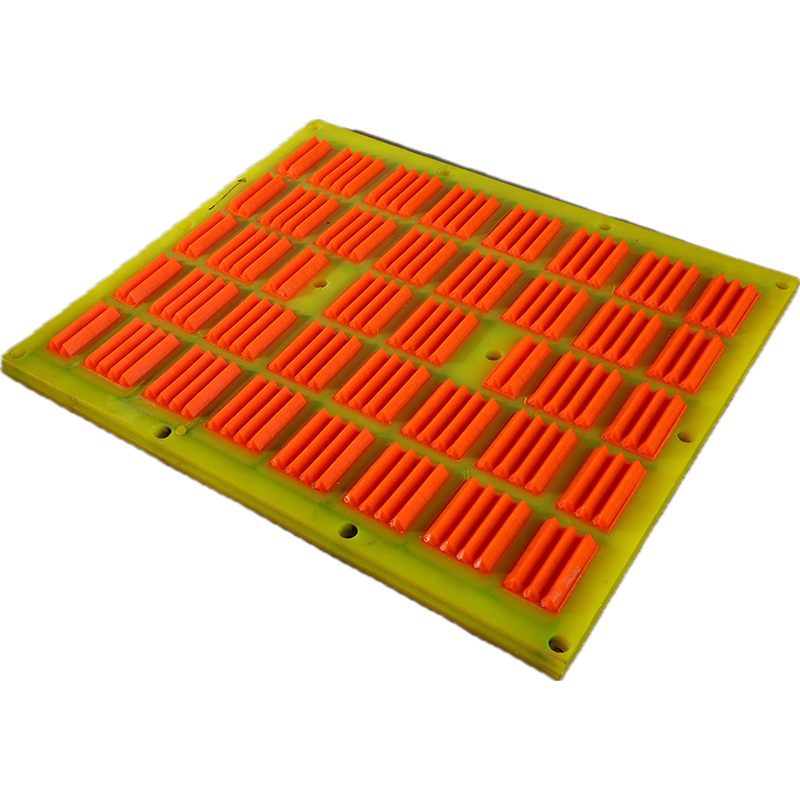

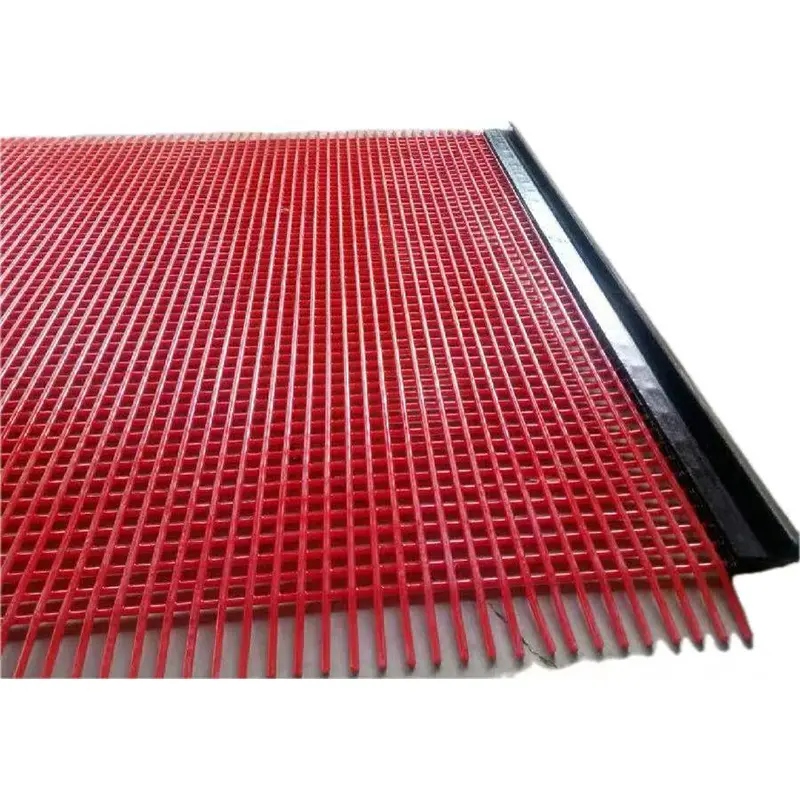

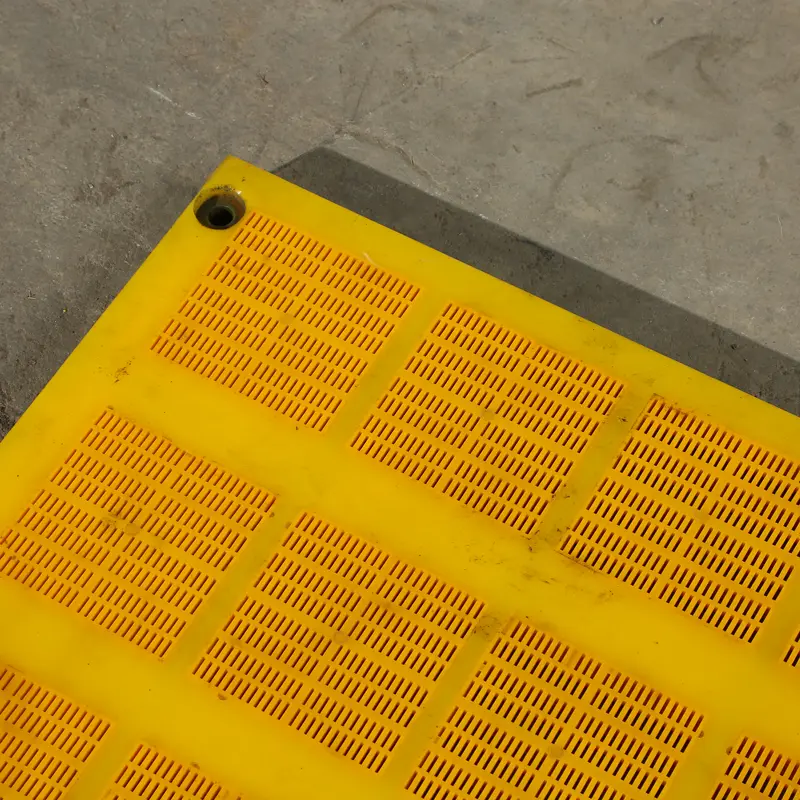

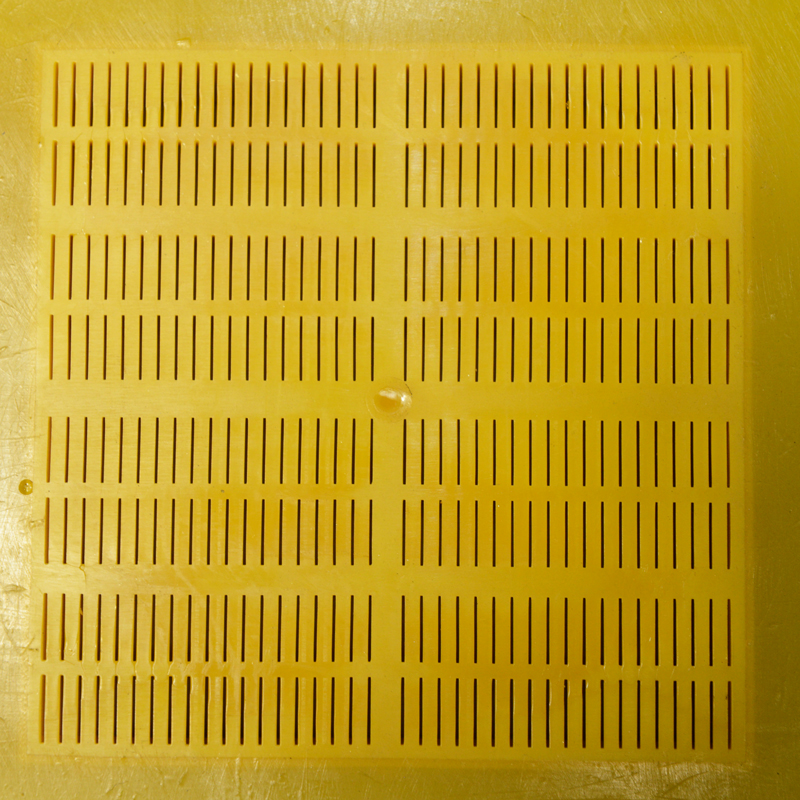

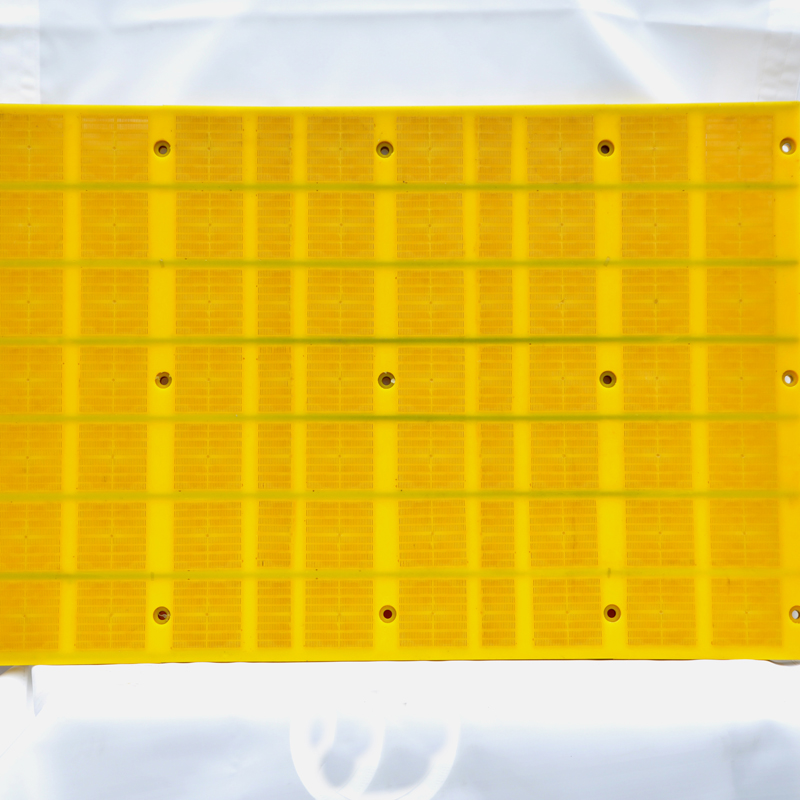

Polyurethane Dehydration Screen

product description

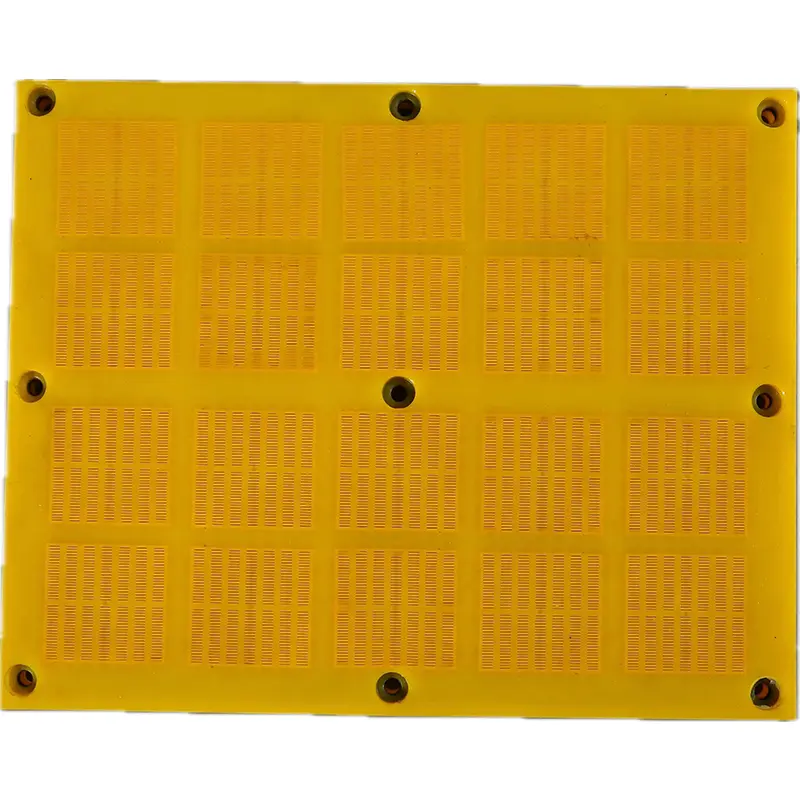

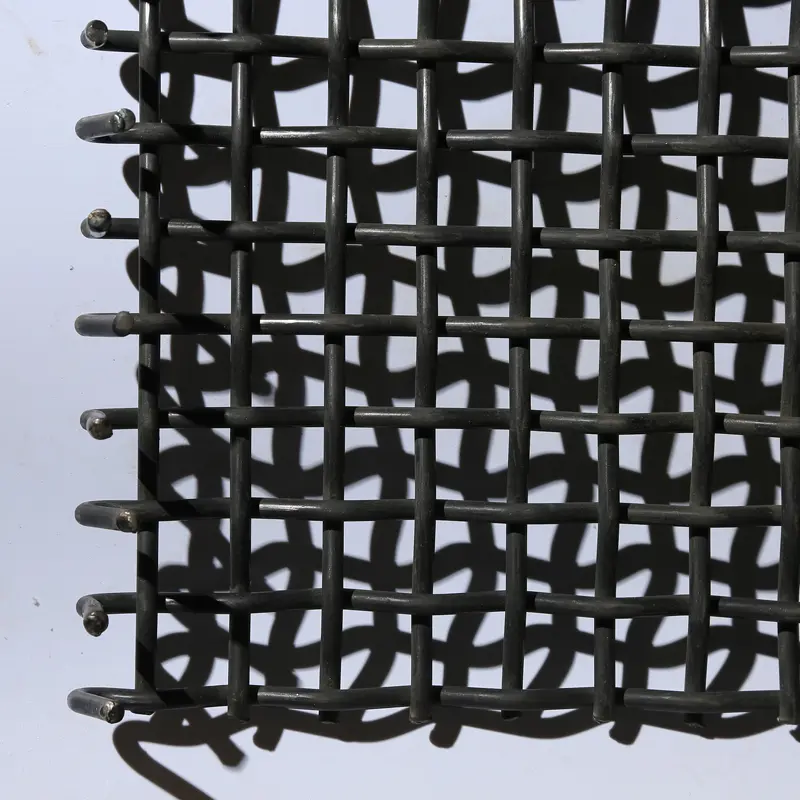

1. High Abrasion Resistance: Polyurethane material itself has excellent abrasion resistance, which enables polyurethane sieves to show durability far exceeding traditional sieves when facing frequent impacts and long-term friction from various materials. In mining, ores are hard and jagged, causing great wear on sieves during screening. However, polyurethane sieves, with their high abrasion resistance, can operate stably for a long time, significantly reducing the frequency of sieve replacement. Compared with metal sieves, their service life can be extended by 2-3 times, significantly reducing equipment maintenance costs and downtime, and improving production efficiency.

2. Excellent Screening Precision: The pore size of polyurethane sieves can be very accurate and is not prone to deformation during long-term use. This ensures that stable screening precision can be maintained during screening operations, effectively controlling the particle size distribution of products. For example, in the chemical industry, the production of fine chemical products requires extremely strict requirements for the particle size of raw materials and finished products. Polyurethane sieves can accurately separate materials of different particle sizes, ensuring the consistency and stability of product quality, and meeting the high-precision screening requirements of chemical production.

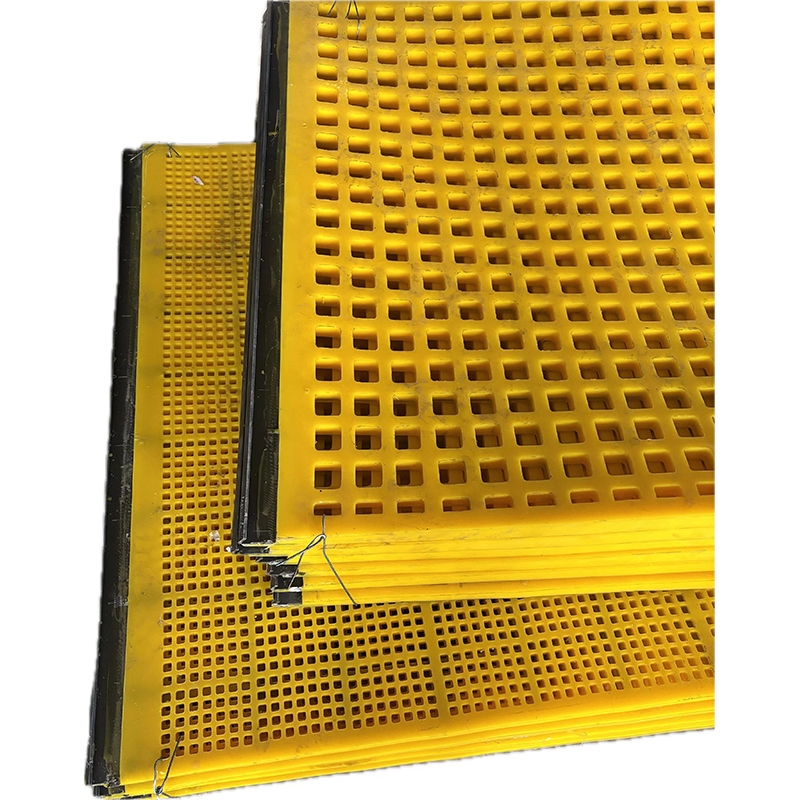

Good Flexibility and Impact Resistance

4. Good Flexibility and Impact Resistance: Polyurethane material has good flexibility, which allows the sieve to buffer the impact force through its own elastic deformation when subjected to material impact, reducing the risk of sieve damage due to impact. In coal screening applications, coal falls from a height and exerts a large impact force on the sieve. Polyurethane sieves, with their flexibility and impact resistance, can withstand such frequent impacts, maintain the integrity of the sieve, and extend its service life.

Corrosion Resistance

5. Corrosion Resistance: Polyurethane has good tolerance to many chemicals, including common acids, alkalis, salts, etc. In some chemical and environmental protection industries, materials may be corrosive, and traditional metal sieves are prone to corrosion and damage, affecting screening effectiveness and equipment life. Polyurethane sieves can work stably in corrosive environments without frequent replacement, saving costs for enterprises and ensuring the continuity of the production process.

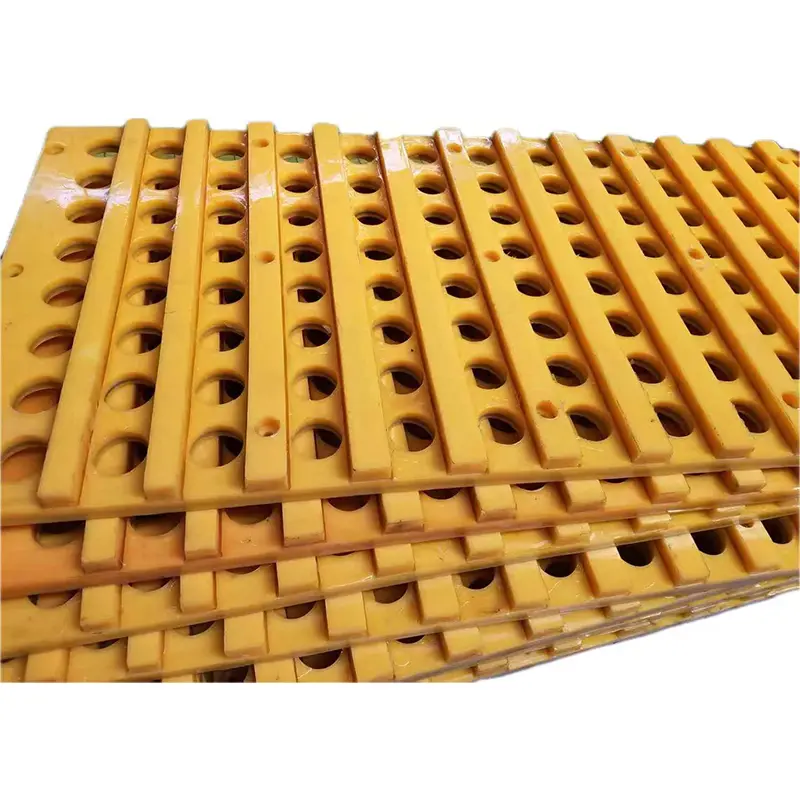

Lightweight Design

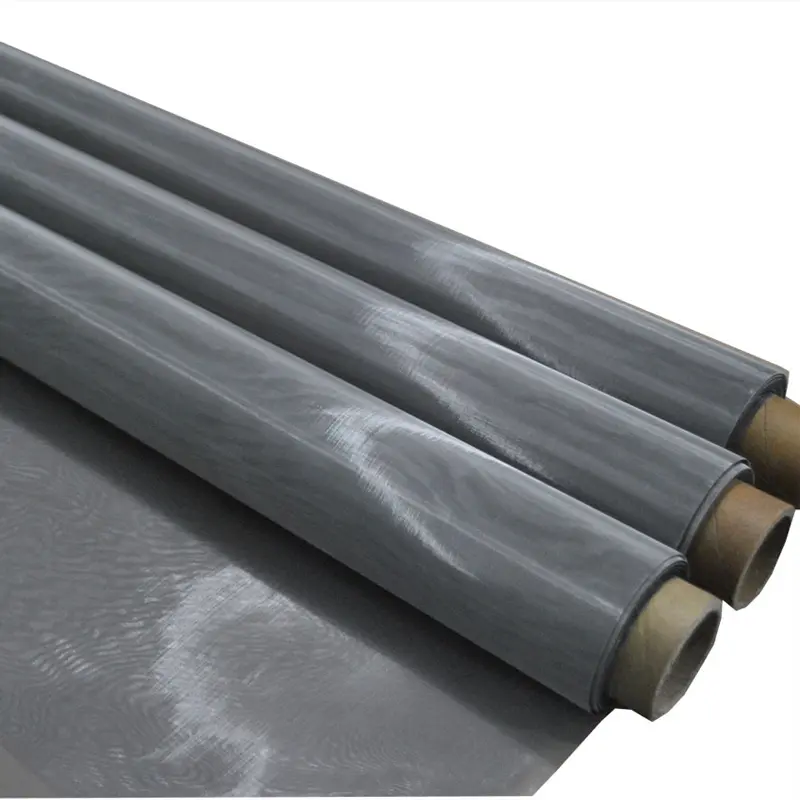

6. Lightweight Design: Compared with metal sieves, polyurethane sieves are significantly lighter. This feature brings great convenience to the installation, disassembly, and transportation of sieves. During installation, no large lifting equipment is required, and the operation can be completed with a small amount of labor, reducing installation difficulty and cost. During transportation, lightweight sieves can reduce transportation energy consumption and logistics costs.

Less Likely to Clog

7. Less Likely to Clog: The surface of polyurethane sieves is relatively smooth, and their elastic characteristics make materials less likely to adhere and accumulate on the sieve. When handling some sticky materials, such as moist clay or materials containing a certain amount of moisture, polyurethane sieves are less likely to clog compared to sieves made of other materials, ensuring the continuous and stable progress of screening operations.

8. Environmentally Friendly and Recyclable: Polyurethane material is recyclable to a certain extent, in line with current environmental concepts. When the sieve reaches the end of its service life, it can be processed through specific recycling processes, reducing waste emissions to the environment and reducing the pressure on enterprises in terms of environmental treatment.

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)