The sustainable development of the screen mesh industry

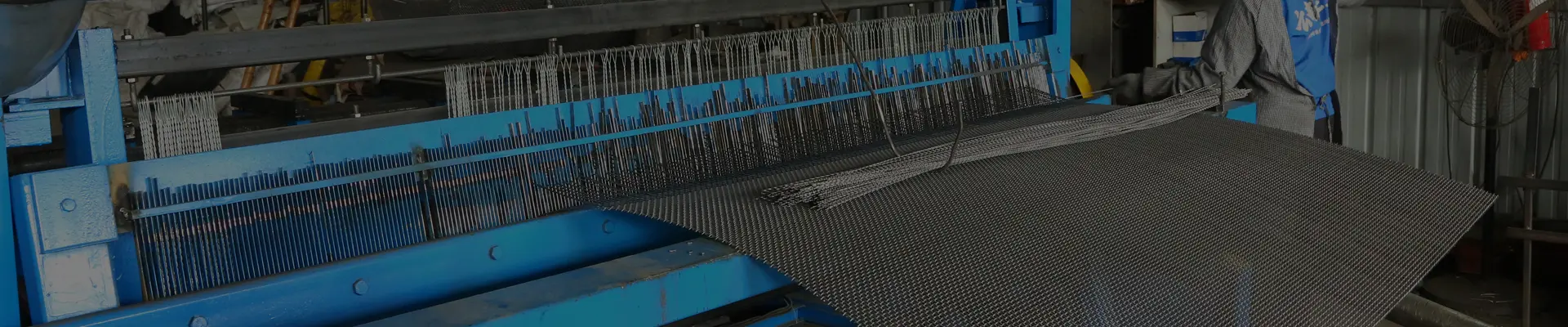

Technological Innovations in Screen Meshes Improve Efficiency and Quality

Henan Taihang Heavy Machinery Obtains Patent for Quick Screen Mesh Replacement: Henan Taihang Heavy Machinery Co., Ltd. has obtained the patent for "A Quick Screen Mesh Replacement Structure for Ore Screens". Through the design of a screen frame skeleton, screen mesh, arc-shaped pressing frame, and arc-shaped frame, this patent shortens the screen mesh replacement time, solves the problems of screen mesh stability and strength under high-load operation, improves the efficiency of the mining industry, and reduces maintenance costs and the dependence on operational techniques.

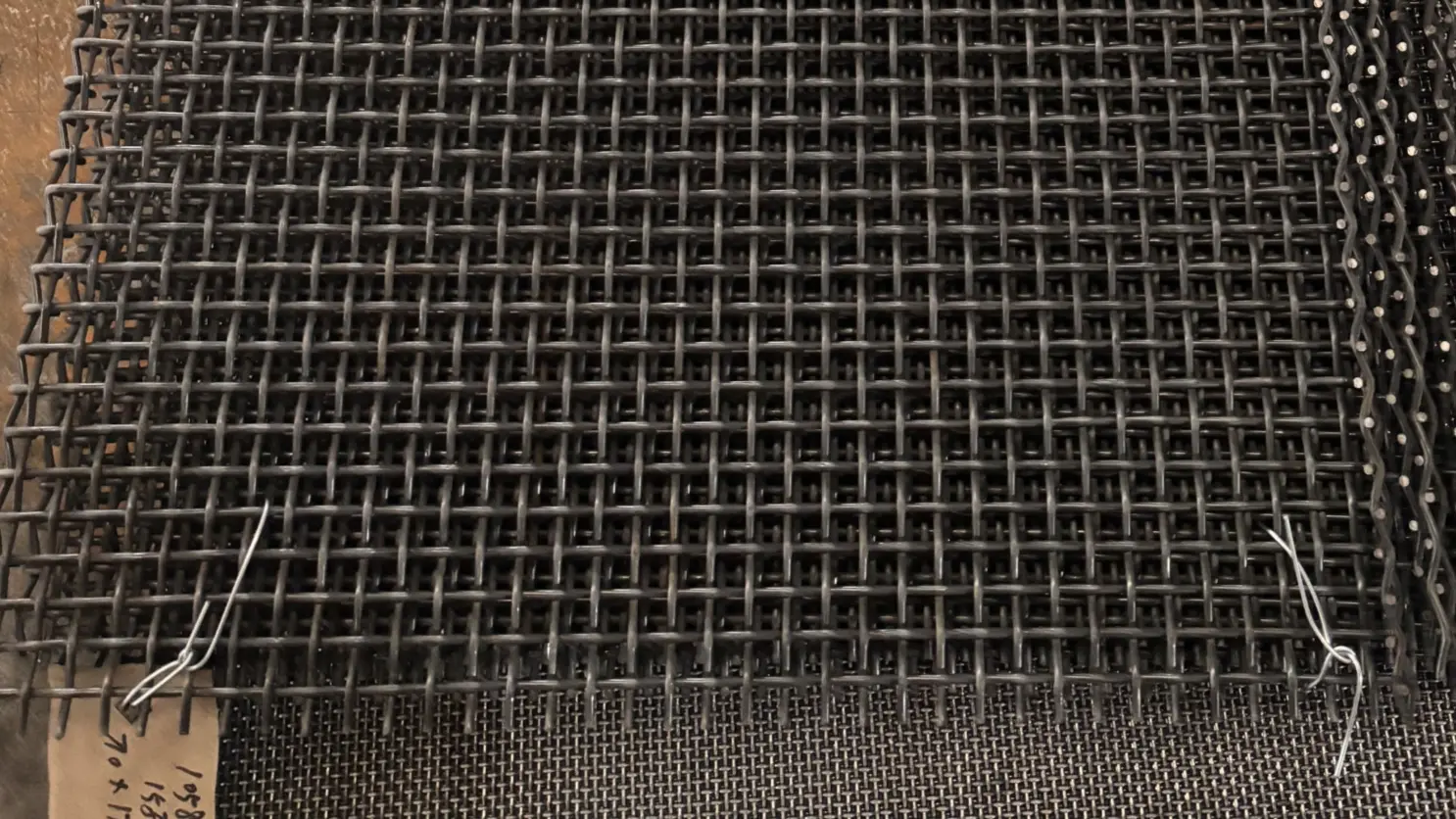

Henan Taihang Heavy Machinery Obtains Patent for Variable Diameter of Ore Screen Mesh Holes: The "A Variable Diameter Structure of Ore Screen Mesh Holes" patent of this company features longitudinal and transverse screen mesh components set on the frame. The connecting blocks are connected by spring devices of the same specification to form a synchronous adjustment system. The linear module can drive the connecting blocks to move, synchronously expanding or reducing the aperture of the transverse screening components. This improves the efficiency and accuracy of ore screening and reduces resource waste.

Yancheng Taige Technology Obtains Patent for Vibrating Cleaning Screen with Graded Screening Function: The "Vibrating Cleaning Screen with Graded Screening Function" patent of Yancheng Taige Technology Co., Ltd. consists of a vibrating base and a grading mechanism. By adjusting the grading screen plate through a simple mechanical rotation method, it can meet the screening requirements of various particle sizes. It is applicable to industrial fields such as building materials, cement, mineral powder, and chemical fertilizers, reducing manual operation errors and labor costs, which is in line with the concept of sustainable development.

Meinong Biology Obtains Patent for New Rotating Granulator Screen Mesh Technology: Meinong Biology has obtained the patent for "A Rotating Granulator Screen Mesh to Prevent Deformation and Bursting". This technology enhances the stability of the reinforced flange at the outer center of the screen mesh, does not set screen mesh holes at the center of the screen mesh, and designs an intermittent groove in the middle of the grinding knife. These measures reduce the pressure of materials on the screen mesh, improve the service life of the screen mesh, reduce the replacement frequency, and promote the production of high-quality products.

Fujian South Road Machinery Applies for Patent for Vibration Screen Monitoring: Fujian South Road Machinery Co., Ltd. and Huaqiao University jointly applied for the patent for "A Vibration Screen Mesh Damage Monitoring Method and Device Based on Deep Learning". An image acquisition platform is built on the chute of the manufactured sand. A lightweight convolutional neural network is used to train the classification model, which is then deployed on an edge computer to build an online monitoring system. This system can automatically and real-time analyze images and issue an alarm when the number of damaged screen meshes reaches a certain level, reducing waste materials and losses caused by screen mesh damage.

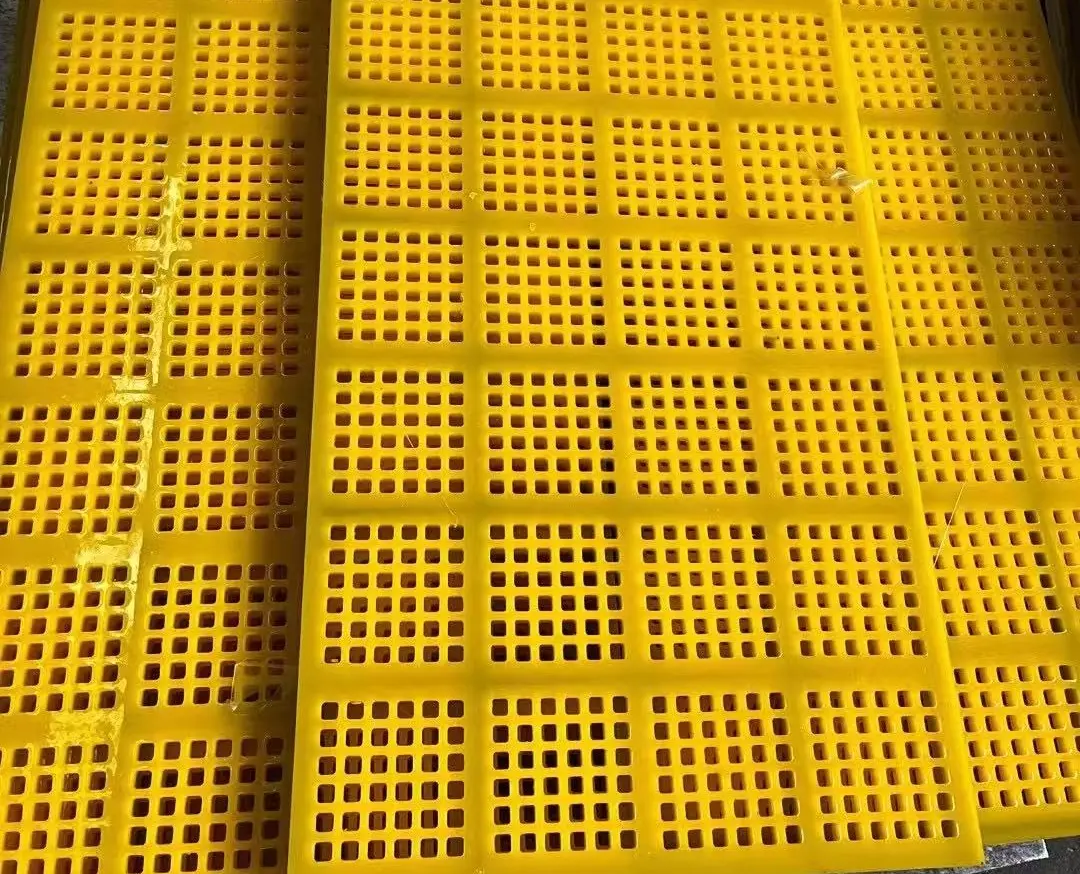

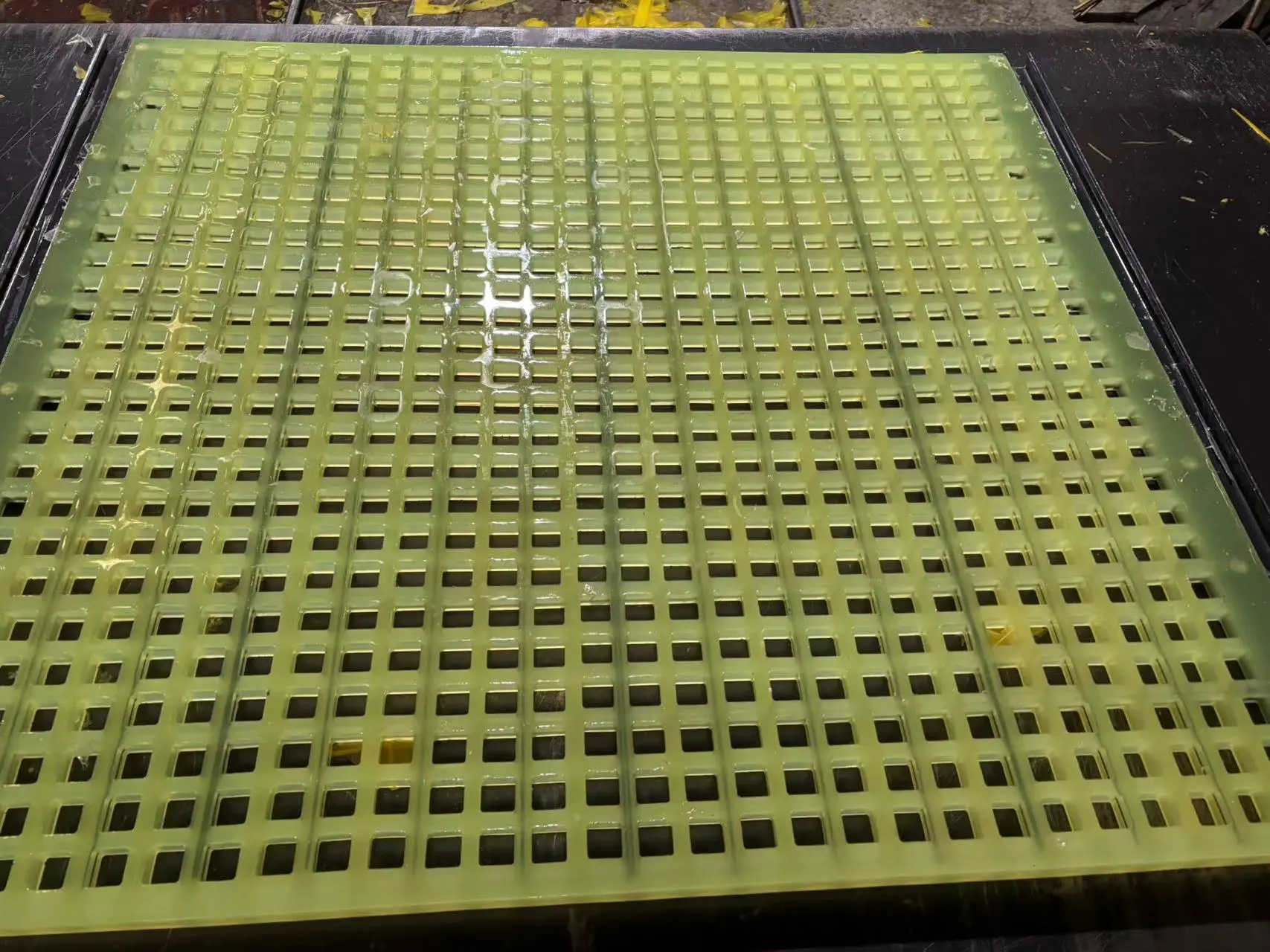

Nanchang Xinli Wear-resistant Materials Company Obtains Patent for Wear-resistant Polyurethane Screen Mesh. The "A Wear-resistant Polyurethane Screen Mesh" patent of Nanchang Xinli Wear-resistant Materials Co., Ltd. The screen mesh is composed of an upper filter basket and a lower filter basket. Through the design of clamping blocks, card slots, and fixing bolts, etc., it reduces the direct impact of materials on the filter screen, improves wear resistance and service life. It can also quickly replace filter screens with different apertures to meet the needs of multiple fields such as environmental protection, mining, and building materials.

Industry Development and Forums Promote Sustainability:

On December 10th, the Screen Mesh and Filter Materials Industry Development Forum with the theme of "Scientific and Technological Innovation assisting in creating new productive forces of quality" was held in Fuyang, Anhui. Li Lingshen, the vice president of the China National Textile and Apparel Council, emphasized in the keynote report that the textile industry should explore new productive forces of quality in science and technology from four aspects: boosting the optimization and upgrading of basic industries through high-end transformation, empowering the industry to improve quality and efficiency with digital and intelligent technologies, achieving the green and sustainable development of the industry with green and low-carbon technologies, and continuously expanding the industry boundary through cross-border collaborative innovation.

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)