Does the anti - clogging screen really prevent clogging

Mining Field - A Large Copper Ore Dressing Plant

Background: During the ore dressing process, the mined copper ore needs to be screened to separate ores of different particle sizes for subsequent processes such as grinding and flotation. Due to the humid mining environment of copper ore, the ore particles are irregular in shape and have a relatively high hardness. Traditional screen meshes are prone to blockage, which affects the ore dressing efficiency.

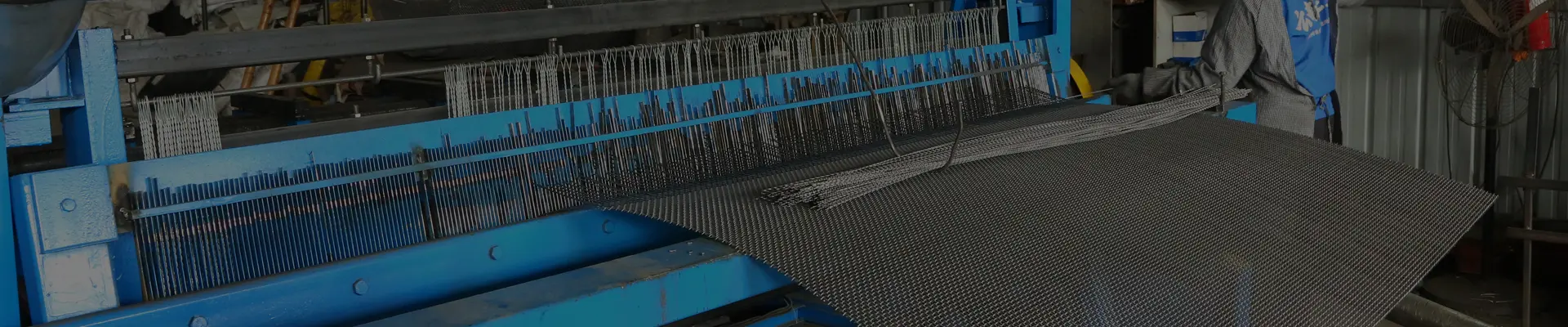

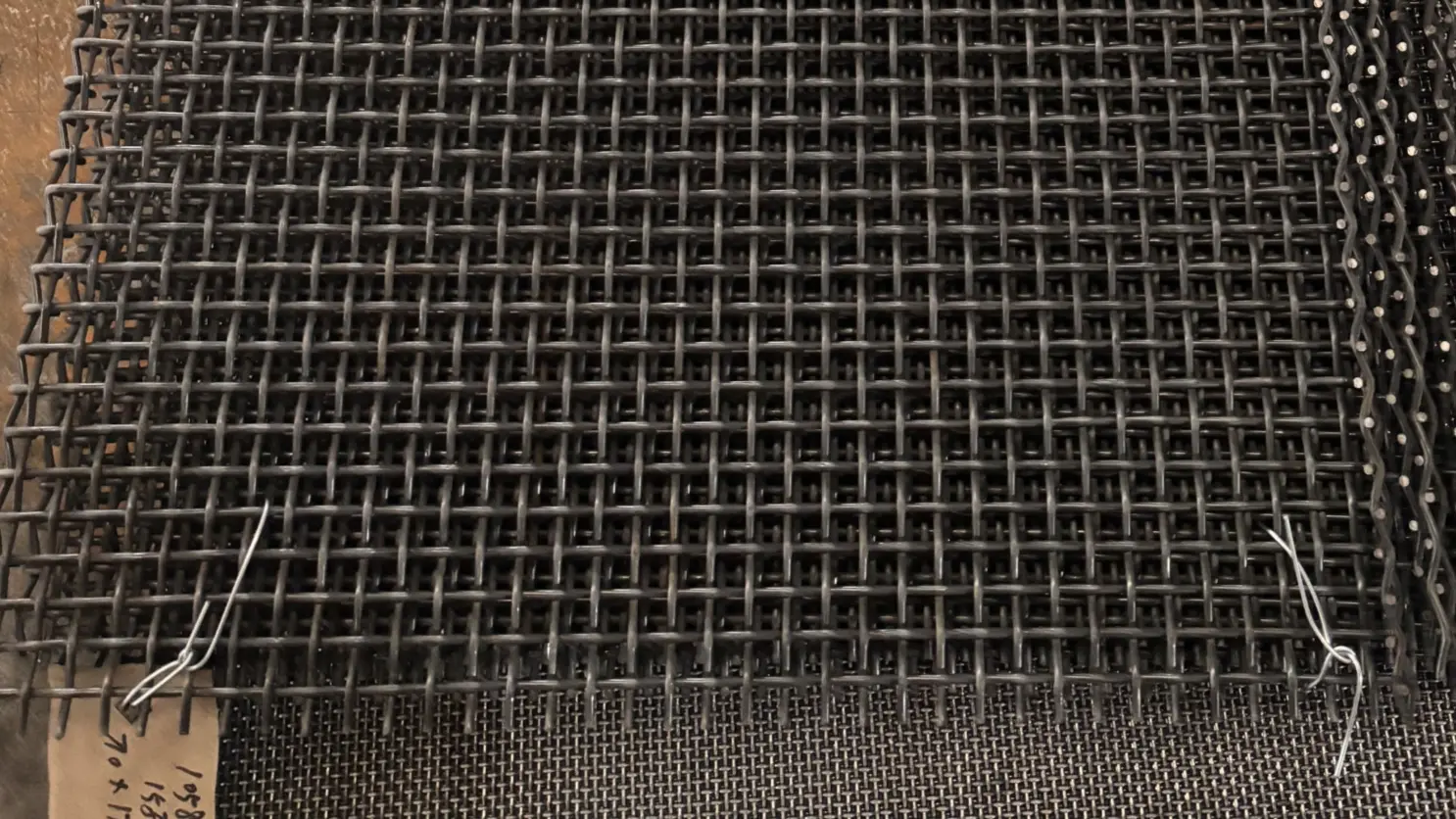

Solution: The plant adopted a manganese steel anti-blocking screen mesh. The manganese steel screen mesh undergoes a special heat treatment, resulting in high hardness, excellent strength, and toughness. During the screening process, it can withstand the heavy pressure and frequent impacts of the ore, effectively resisting the wear caused by the ore. Its special structural design and material properties make it difficult for even irregularly shaped ores to block the screen mesh.

Effect: After using the anti-blocking screen mesh, the ore screening efficiency of the dressing plant has increased by approximately 30%. In the past, due to frequent screen mesh blockages, the equipment needed to be shut down for cleaning. Now, the number of cleaning times has been significantly reduced, the overall operating time of the equipment has been extended, and the screening accuracy of copper ore has also been significantly improved, providing higher-quality raw materials for subsequent ore dressing processes.

Building Materials Industry - A Sand and Gravel Processing Plant

Background: During the sand and gravel processing, the mined stones need to be crushed and then screened into different specifications of sand and gravel for construction projects such as concrete production. The sand and gravel have large particles and a rough texture. Traditional screen meshes are easily blocked by sand and gravel, requiring frequent replacement. This increases production costs and downtime.

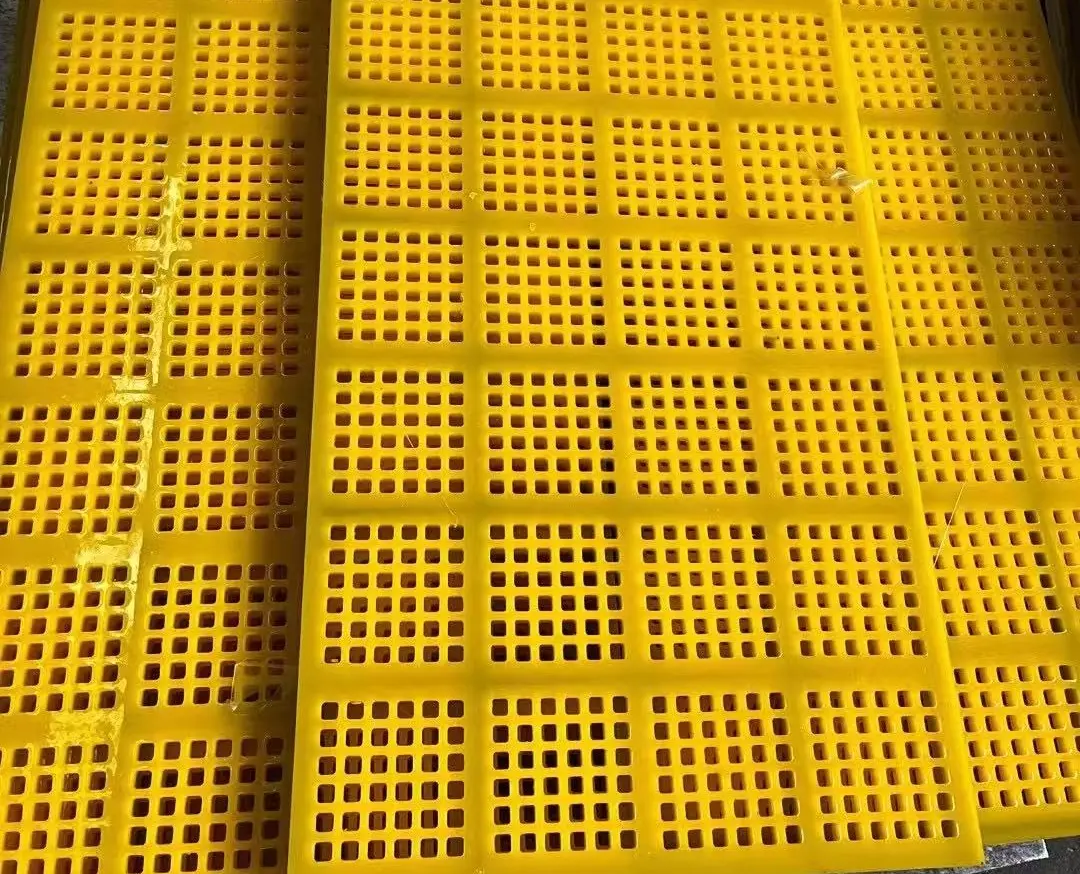

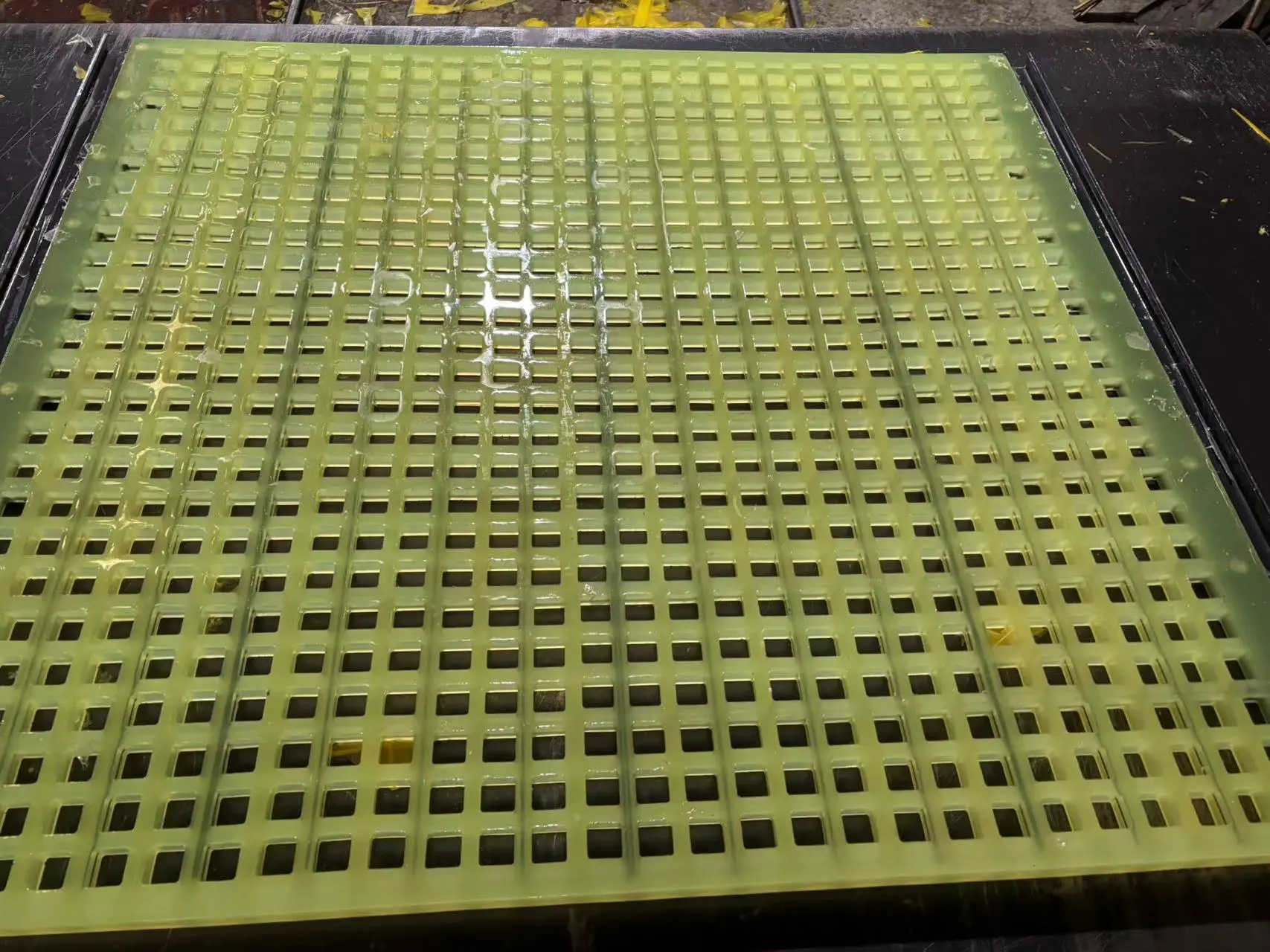

Solution: The processing plant adopted a polyurethane anti-blocking screen mesh. The elasticity and abrasion resistance of polyurethane enable it to adapt to the rough texture of sand and gravel. During the screening process, the screen mesh can elastically deform in response to the impact of sand and gravel, effectively preventing the sand and gravel from clogging the screen holes.

Effect: The use of the anti-blocking screen mesh has increased the sand and gravel screening efficiency by approximately 35% and extended the service life of the screen mesh by about 60%. This significantly reduces production costs. At the same time, it ensures the screening quality of sand and gravel, providing a stable supply of sand and gravel for construction projects

There are mainly the following types of materials for anti-blocking screen meshes:

Stainless Steel

Features: Stainless steel has excellent corrosion resistance, enabling it to be used for a long time in complex environments such as humid conditions and in the presence of acids and alkalis. For example, during the ore screening process in the mining industry, the ore pulp may be corrosive, and the stainless steel screen mesh can effectively resist corrosion and extend its service life. It also has high strength, capable of withstanding large impact forces and pressures, and is not easily deformed during the vibration screening process. Moreover, stainless steel is easy to clean, with a smooth surface, so that materials are not likely to adhere, which helps to keep the screen mesh unobstructed.

Application Scenarios: It is widely used in the food processing industry, such as the screening of flour, starch, etc., to ensure food hygiene and safety. In the chemical industry, it is used for screening various chemical raw materials and products, such as plastic pellets and chemical powders. In the mining field, it is used for screening ores and mineral powders.

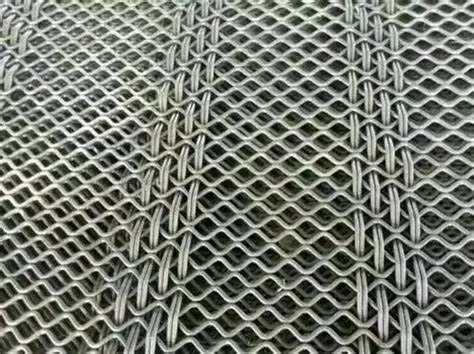

Polyurethane

Features: Polyurethane materials have excellent elasticity. When subjected to the impact of materials, they can produce a certain degree of elastic deformation, thereby reducing the blockage of the screen mesh by materials. It has good abrasion resistance and can withstand the long-term friction of materials. Especially when dealing with materials with relatively high hardness and irregular particle shapes, it can maintain a good working state. Additionally, the polyurethane screen mesh has a high opening rate, which means that more materials can pass through the screen mesh during the screening process, improving the screening efficiency.

Application Scenarios: In the coal industry, it is used for the screening and classification of coal to effectively prevent coal blocks and coal powder from blocking the screen mesh. In the building materials industry, such as the screening of sand and gravel, its high elasticity and abrasion resistance can adapt to the rough texture and irregular shapes of sand and gravel, ensuring the smooth progress of the screening work.

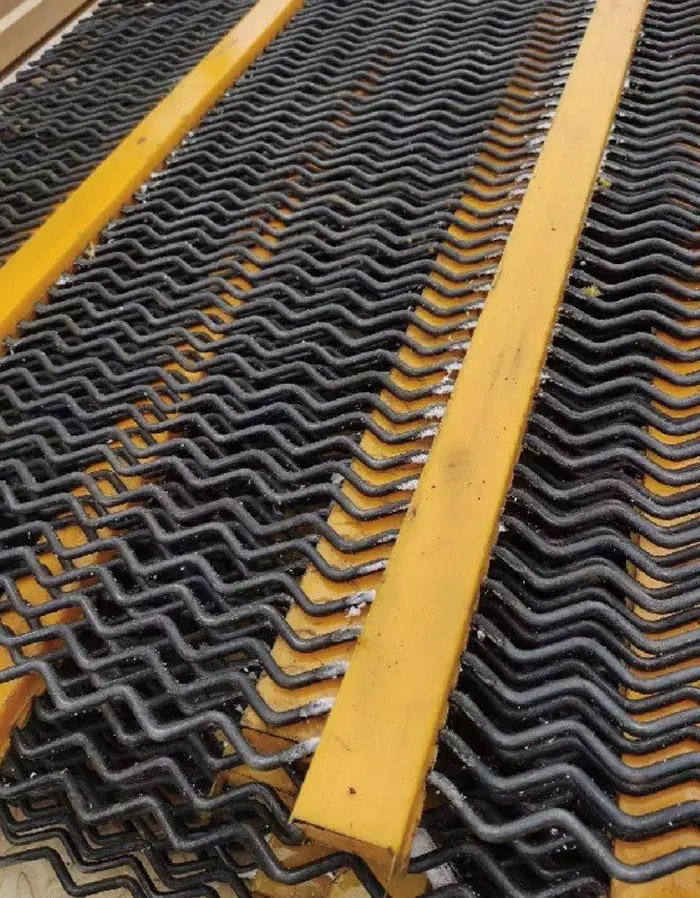

Manganese Steel

Features: Manganese steel has outstanding strength and toughness. It can withstand high-intensity screening operations. In large-scale mines or stone processing plants where a large amount of materials need to be processed, the manganese steel screen mesh can effectively resist the heavy pressure and wear of materials. After a special heat treatment process, the hardness of the manganese steel screen mesh can reach a very high level, further enhancing its anti-blocking performance.

Application Scenarios: It is mainly used for the rough and fine screening of ores in mining, such as the screening of iron ore, copper ore, etc. In large-scale building stone processing plants, it is used for the grading and screening of stones to meet the needs of different construction projects.

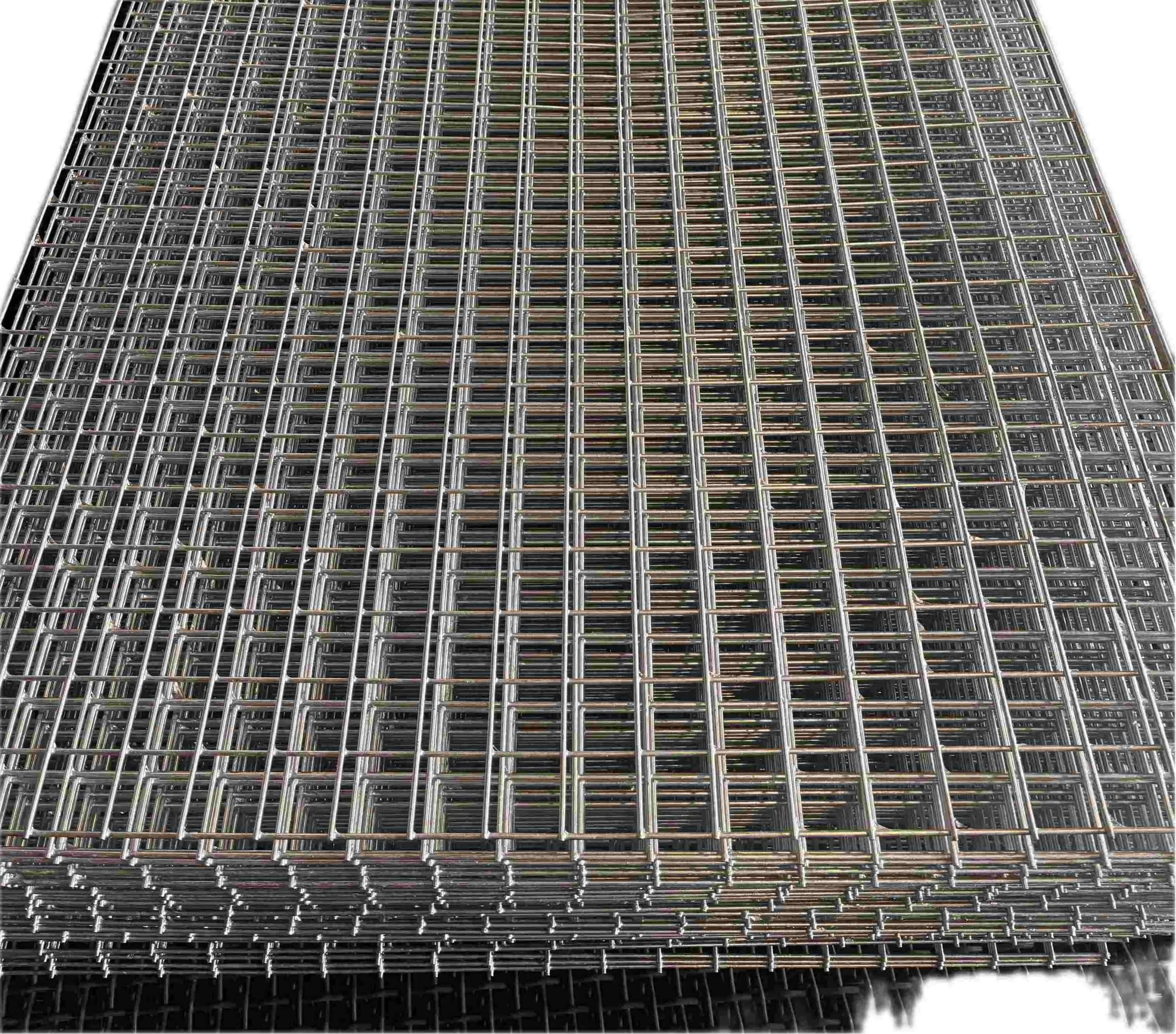

Galvanized Steel Wire

Features: The cost of galvanized steel wire screen meshes is relatively low, making them economically viable. At the same time, the galvanized layer can prevent the steel wire from rusting to a certain extent and improve the corrosion resistance of the screen mesh. There are various weaving methods, and different aperture sizes and shapes can be made according to different screening requirements, providing high flexibility.

Application Scenarios: In the agricultural field, it is used for the screening of grains, seeds, etc. In some small processing plants with relatively low requirements for screen mesh accuracy, such as small stone processing plants and feed mills, it is used for the preliminary screening of materials.

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)