Differences between Polyurethane Sieve and Manganese Steel Sieve

Manufacturing Processes

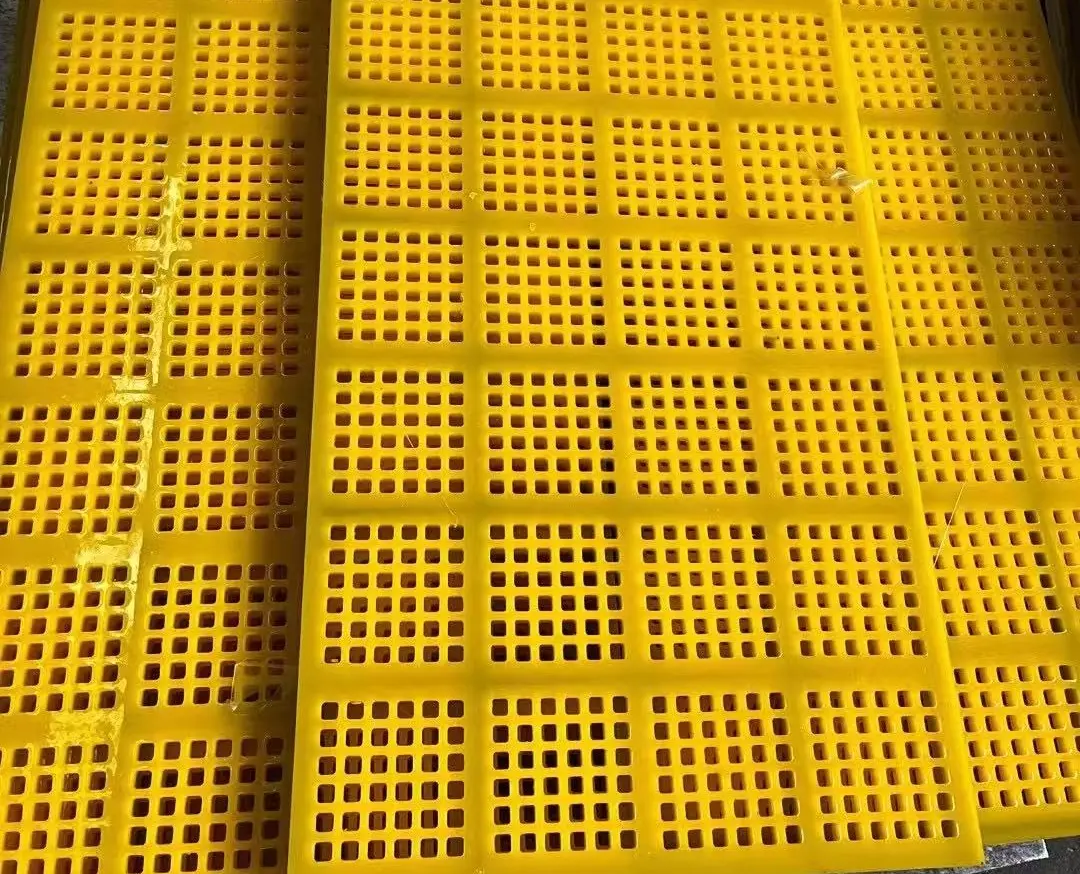

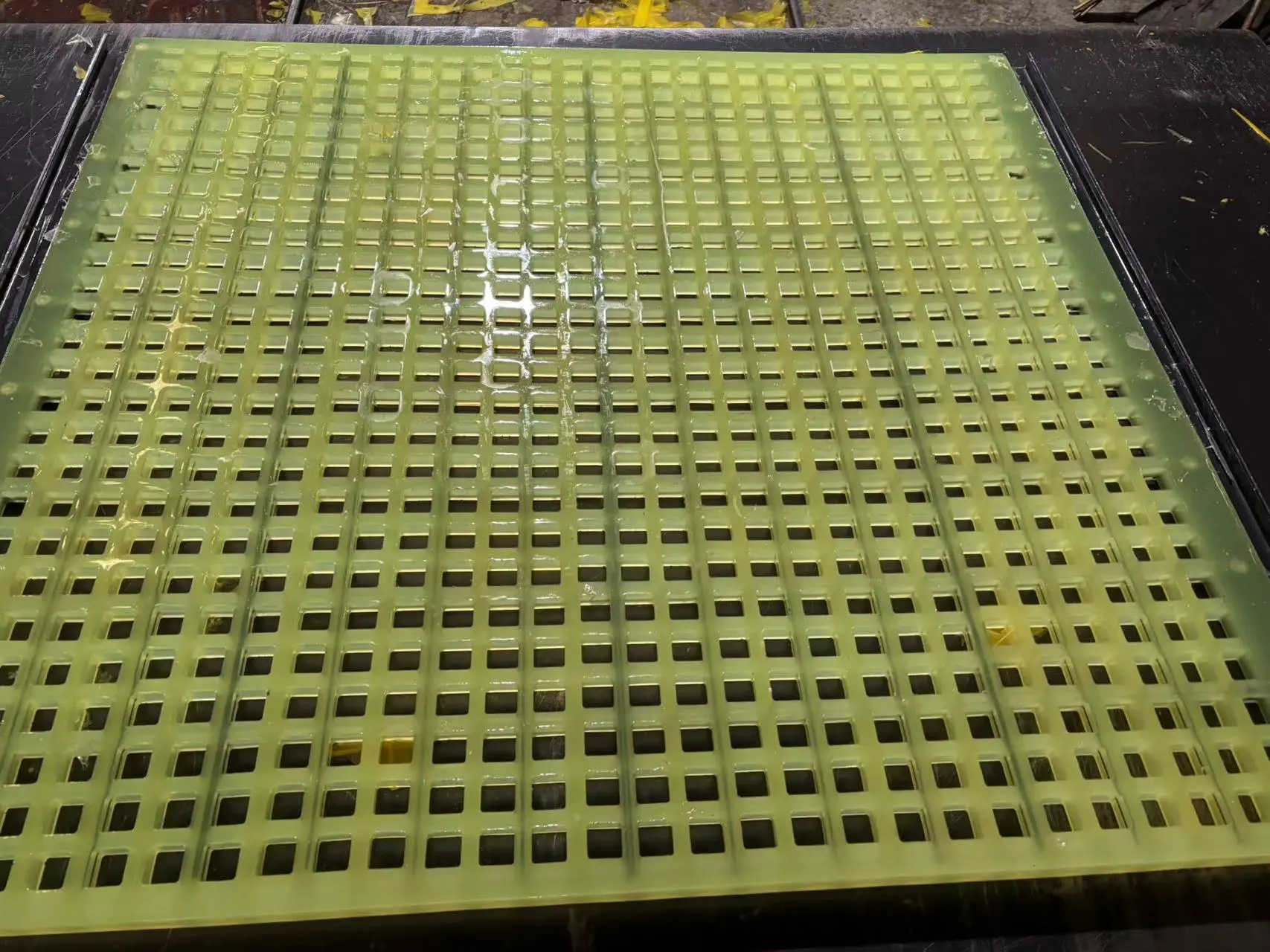

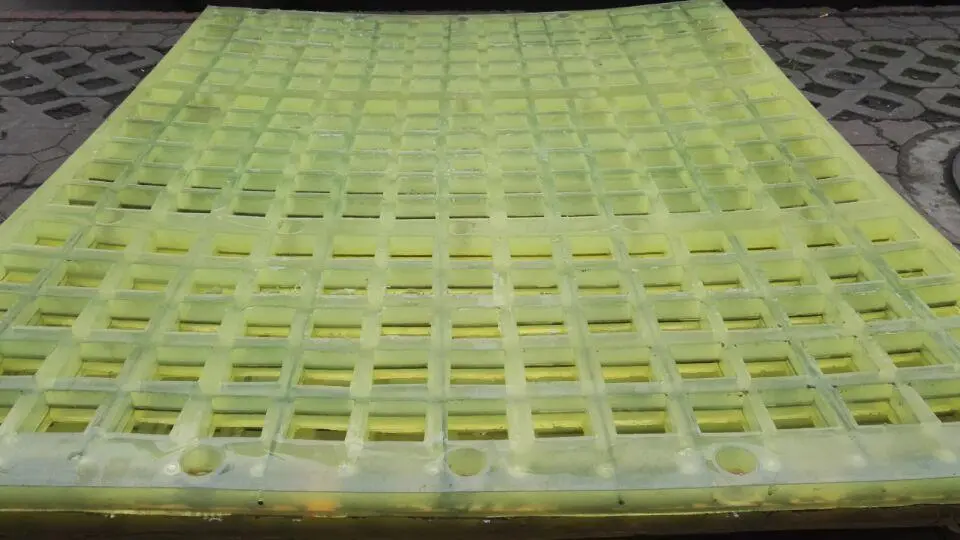

Polyurethane sieves are mainly made of polyurethane and formed by mold casting or compression molding. During the production process, liquid polyurethane raw materials are injected into specific molds and cured by heating to form sieves with specific shapes and specifications. This manufacturing process enables precise control of parameters such as sieve aperture and thickness. Different additives can also be added to the polyurethane according to requirements to enhance the abrasion resistance, corrosion resistance, and other properties of the sieve. In addition, processes such as edge - wrapping and inlaying can be used for polyurethane sieves to improve their structural stability and durability.

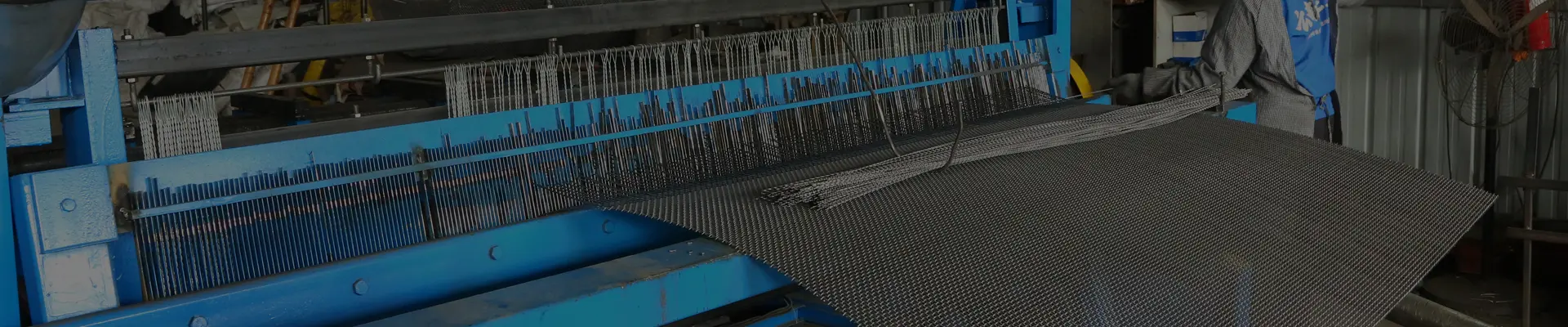

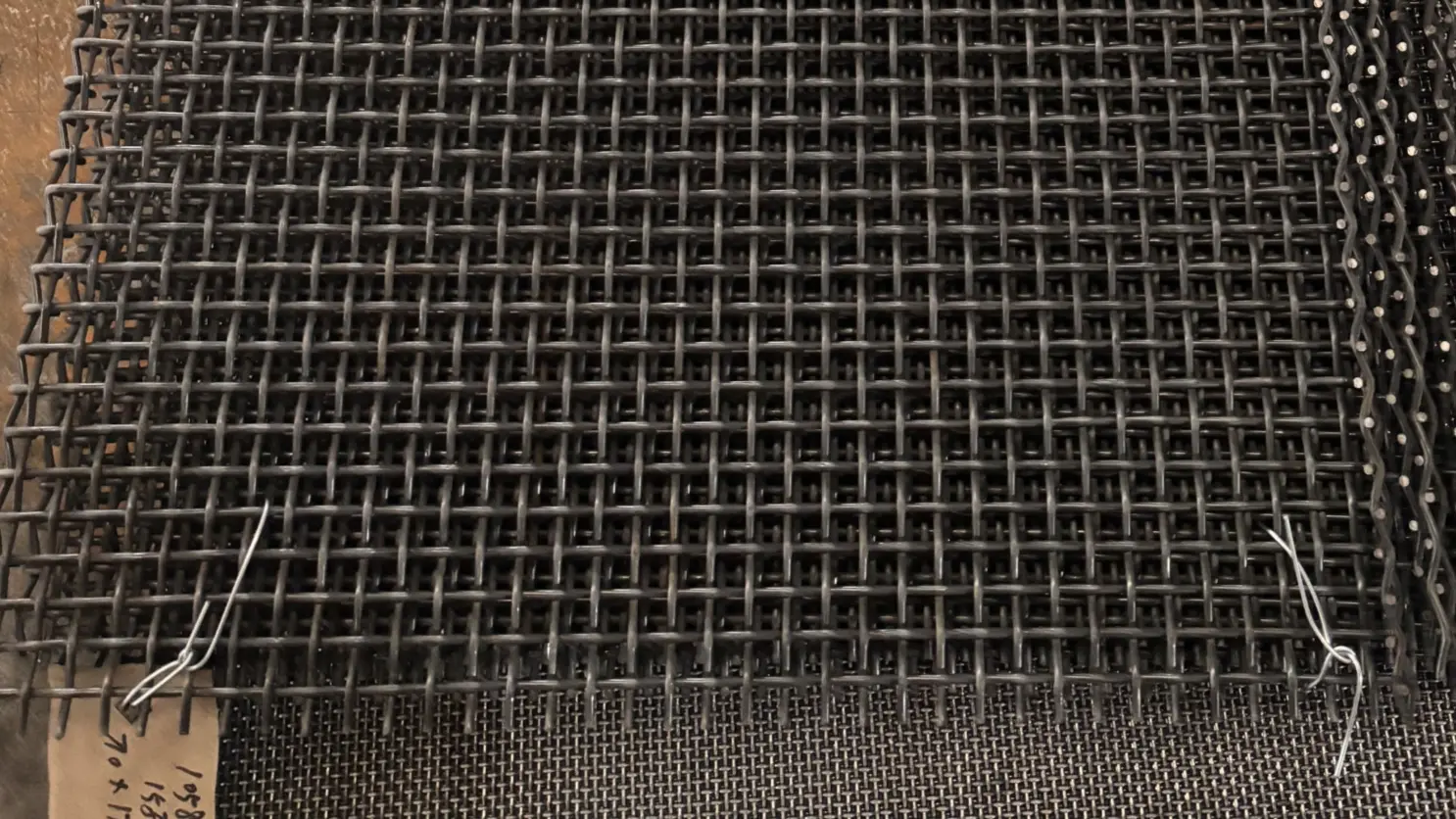

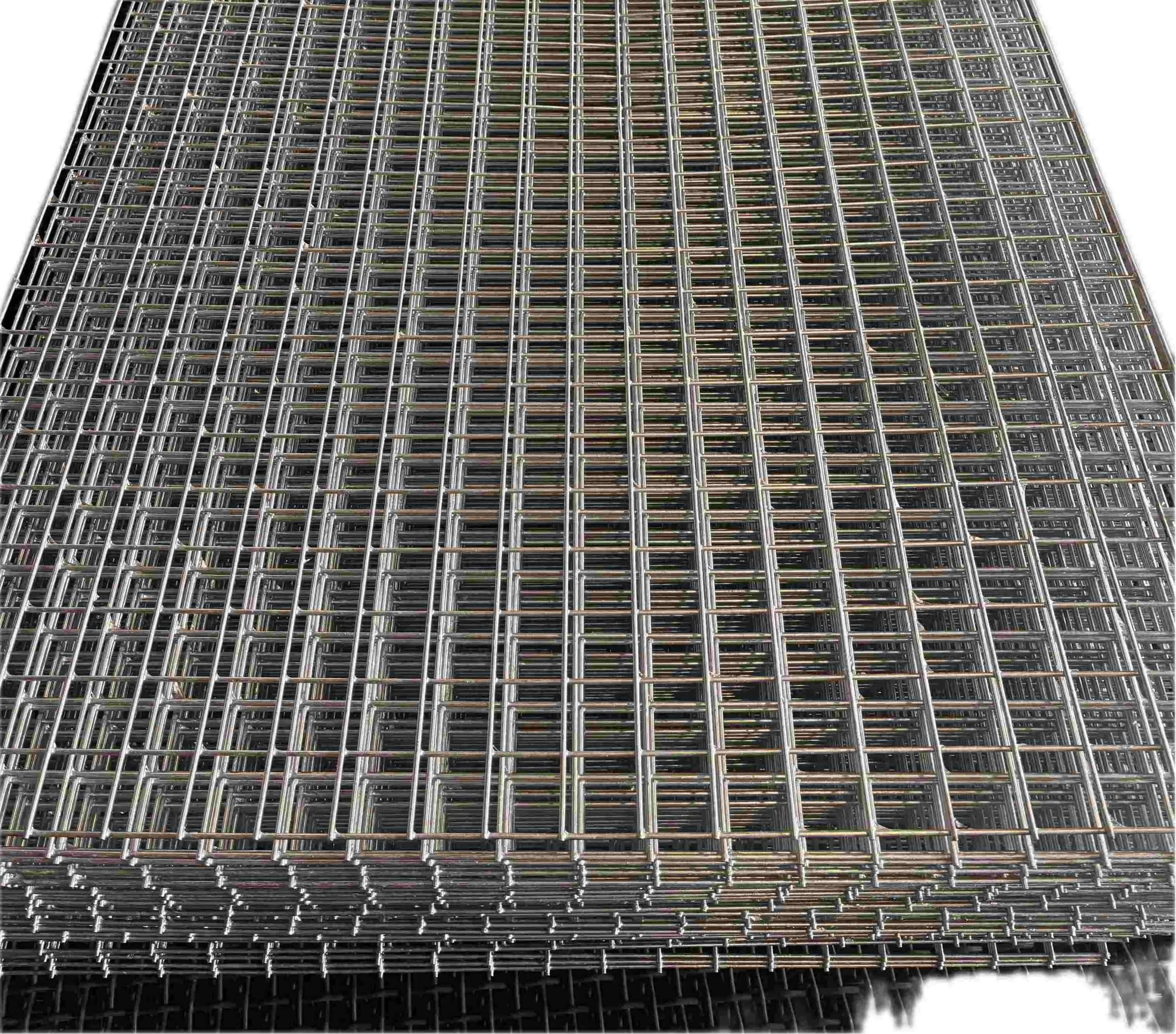

Manganese steel sieves are made of manganese steel as the base material through processes such as weaving, cutting, stamping, and welding. First, the manganese steel plate is cut into appropriate sizes according to the design requirements, then the sieve holes are stamped out using stamping equipment, and finally, each component is assembled into a complete sieve through welding. The welding process is crucial to the quality of manganese steel sieves. High - quality welding can ensure the firm structure of the sieve and reduce the risk of breakage during use. Due to the high hardness of manganese steel, the requirements for equipment and processes during processing are more stringent.

Application Scenarios

Polyurethane sieves, with their good elasticity, abrasion resistance, and corrosion resistance, are widely used in industries such as coal, mining, metallurgy, and environmental protection. In the coal washing process, polyurethane sieves can effectively separate coal from gangue. Their elasticity can reduce the impact of materials on the sieve and lower the probability of material clogging in the sieve holes. In the mining industry, in the screening environment of wet and highly corrosive ores, the corrosion resistance of polyurethane sieves can extend their service life. In addition, in industries with high hygiene requirements such as food and pharmaceuticals, the non - toxic and odorless characteristics of polyurethane sieves make them an ideal choice.

Manganese steel sieves, due to their high strength and hardness, are more suitable for handling large - sized, high - hardness, and high - impact materials, such as the screening of raw ores after crushing in mining, and the screening of materials in high - temperature and high - load environments in the metallurgical industry. In stone processing plants, manganese steel sieves can classify and screen hard stones and withstand the frequent impact and friction of the stones. In the field of construction waste treatment, manganese steel sieves can handle materials with complex shapes and hardnesses, achieving efficient screening.

Service Life

The service life of polyurethane sieves is usually about 6 - 12 months, depending on the use environment and working conditions. In environments with less wear and relatively stable working conditions, their service life can reach 12 months or even longer. However, in harsh conditions with high wear and strong impact, the service life may be shortened to 6 months. Nevertheless, polyurethane sieves are relatively easy to replace, which can reduce downtime.

The service life of manganese steel sieves also varies depending on the working conditions, ranging from several months to one year. Under normal use, manganese steel sieves can maintain good screening performance for a long time. However, once local wear or damage occurs, it is difficult to repair, and the entire sieve may need to be replaced. In addition, after long - term use, manganese steel sieves may break due to fatigue, affecting their service life.

Other Aspects

In terms of weight, polyurethane sieves have a low density and are light in weight, which is convenient for installation and handling and can effectively reduce the load on equipment. Manganese steel sieves have a high density and are heavy, requiring professional equipment and tools for installation, which increases the difficulty and cost of installation. In terms of noise control, polyurethane sieves have good shock absorption and noise reduction performance, generating less noise during operation. Manganese steel sieves produce relatively large noise when impacted by materials and require additional noise reduction measures. In terms of price, due to raw materials and manufacturing processes, polyurethane sieves are relatively expensive, while manganese steel sieves are relatively cheap. However, considering their long service life, the comprehensive costs of the two have their own advantages and disadvantages.

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)