7 operational details to extend the life of polyurethane screens

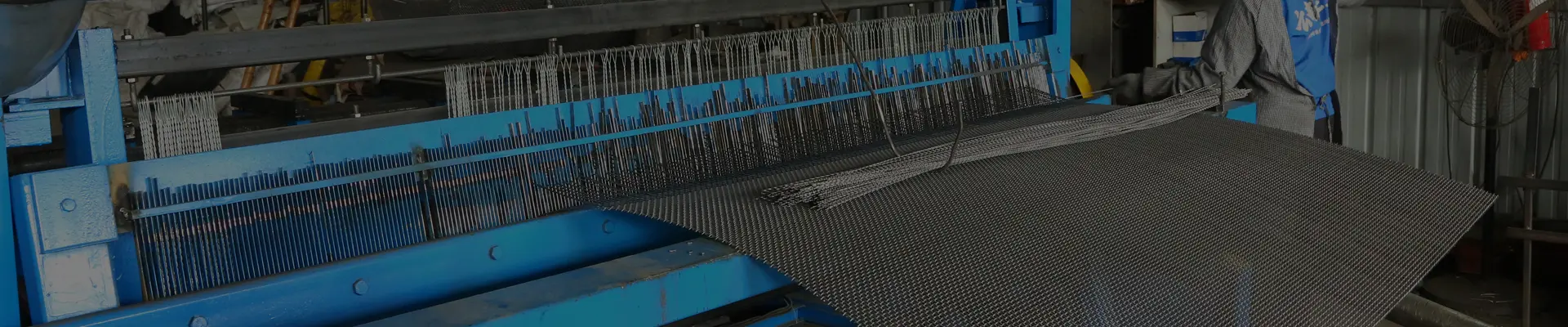

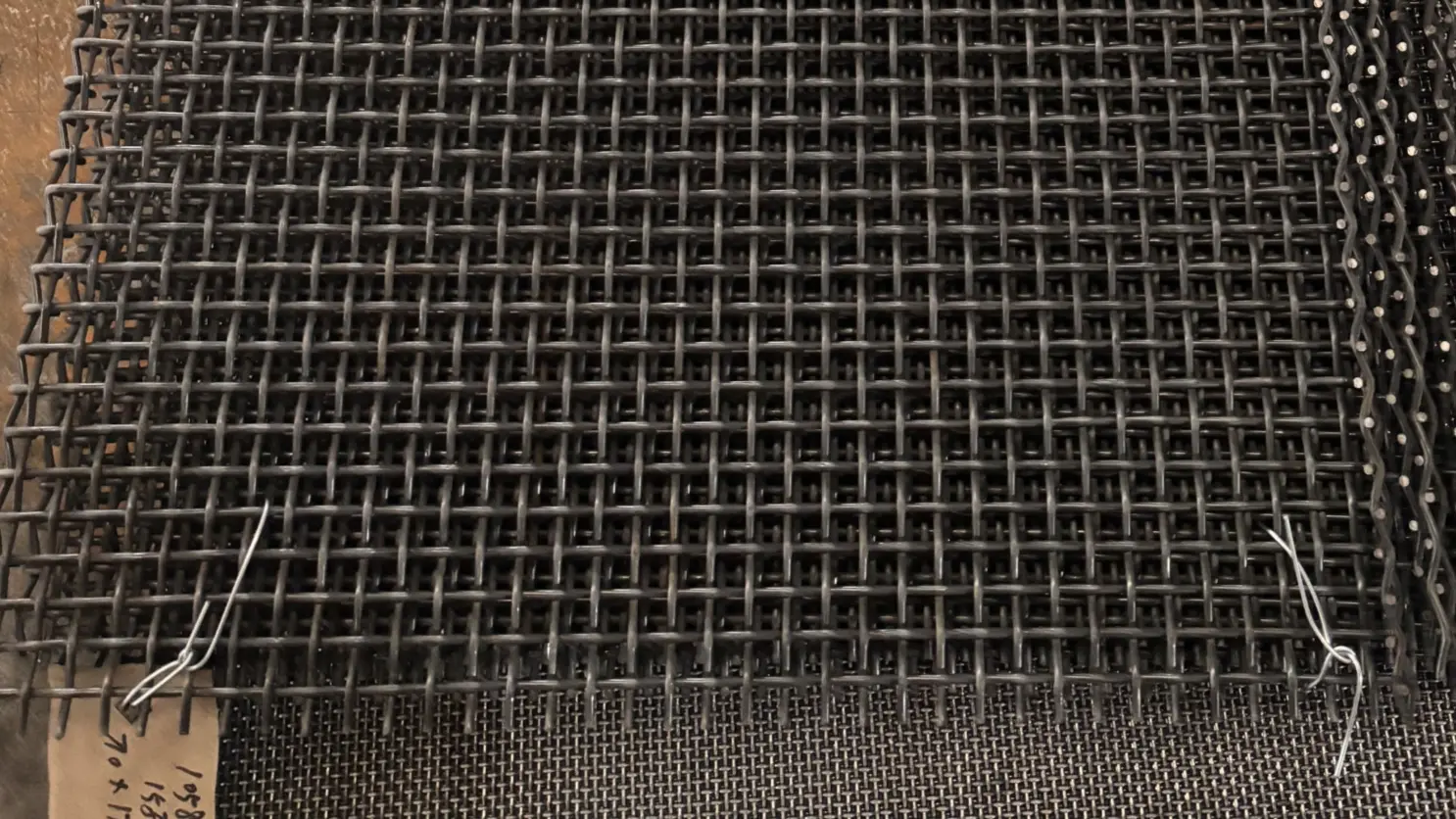

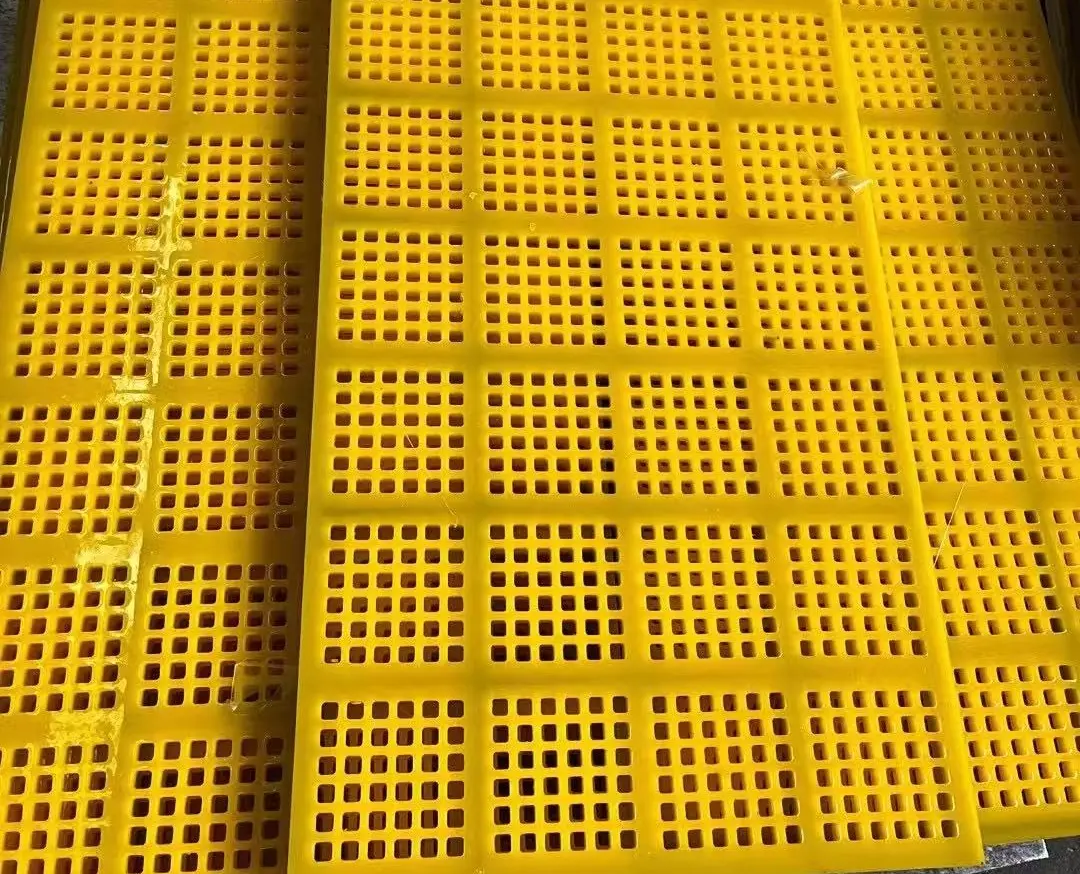

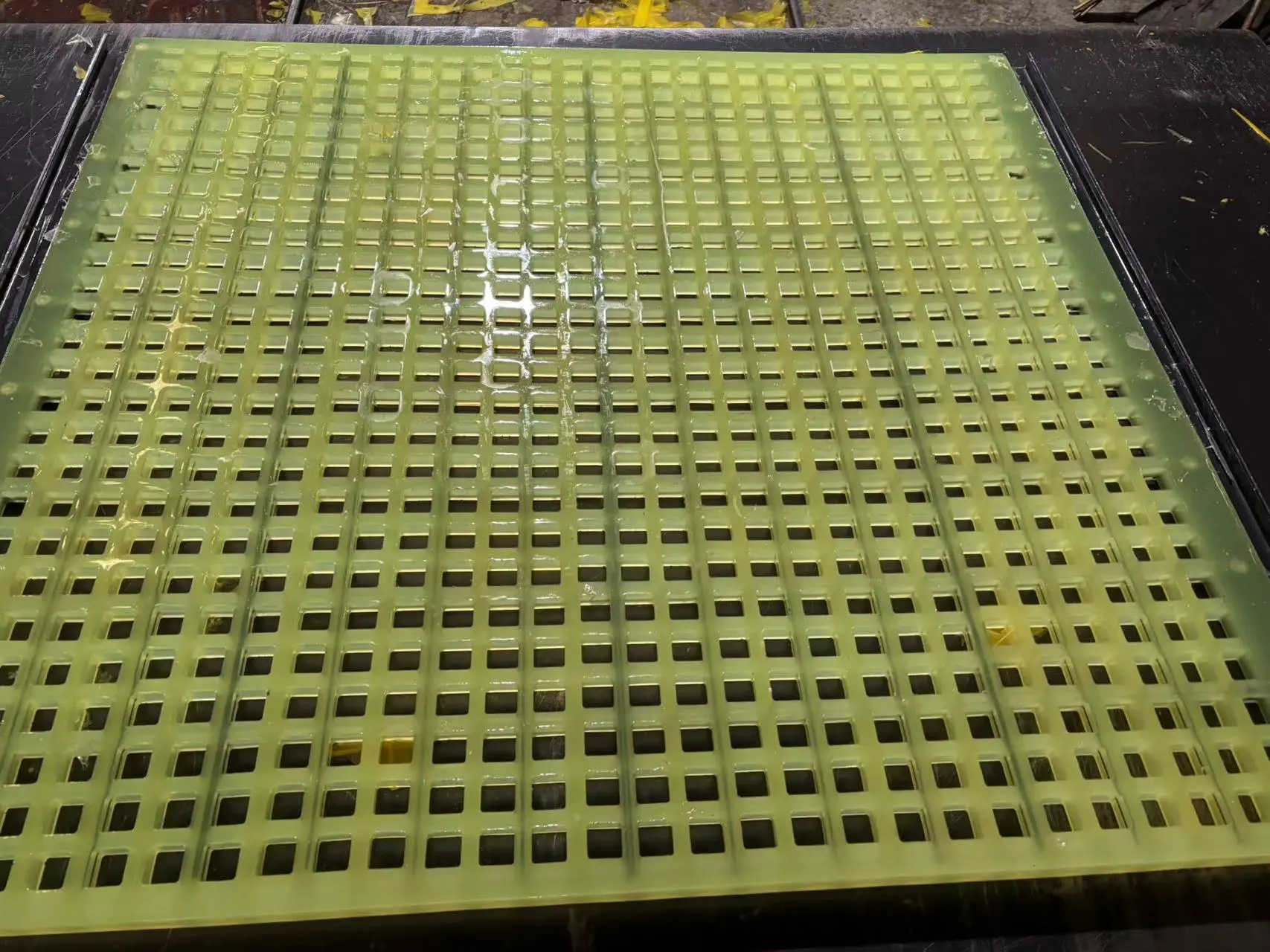

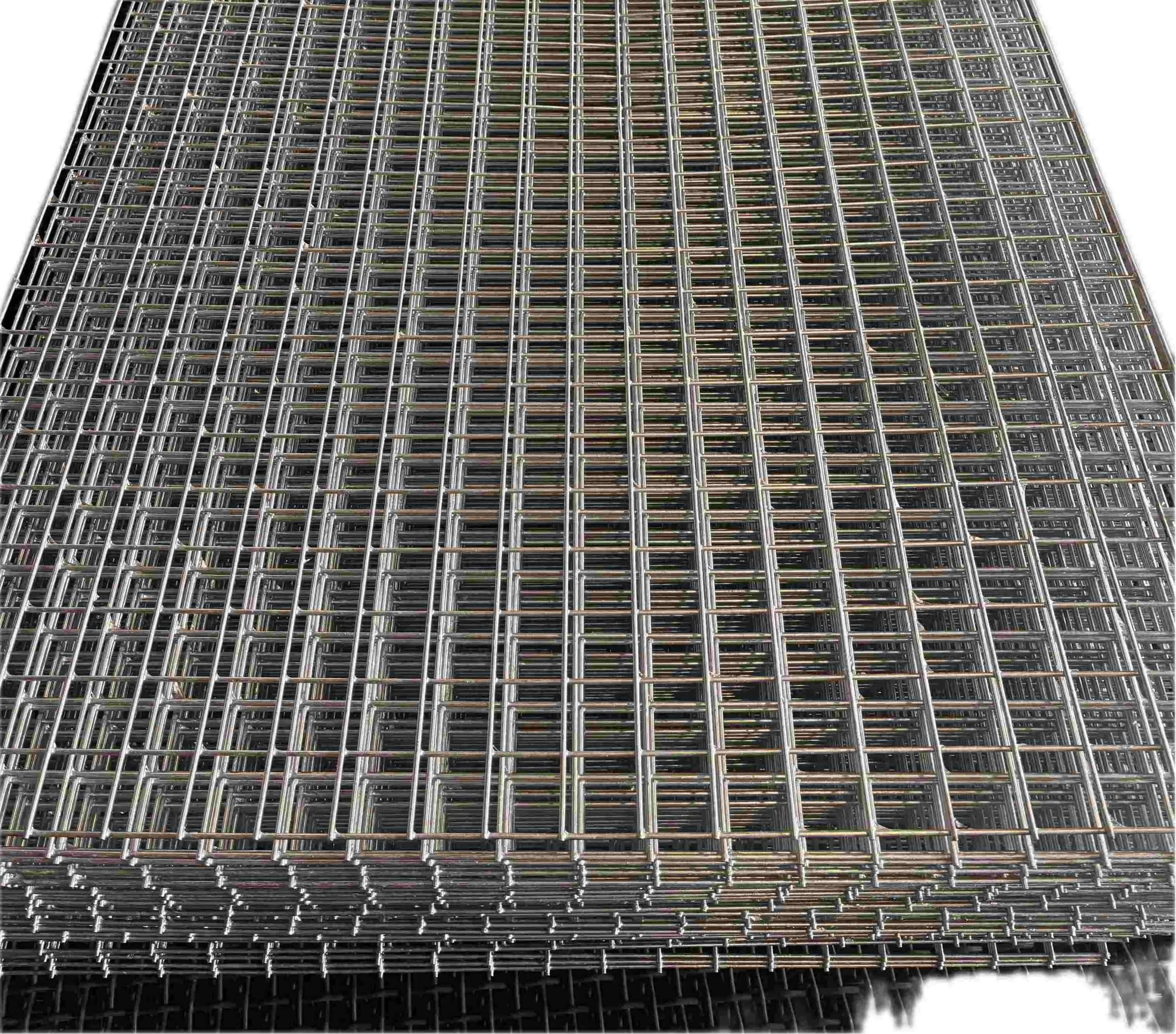

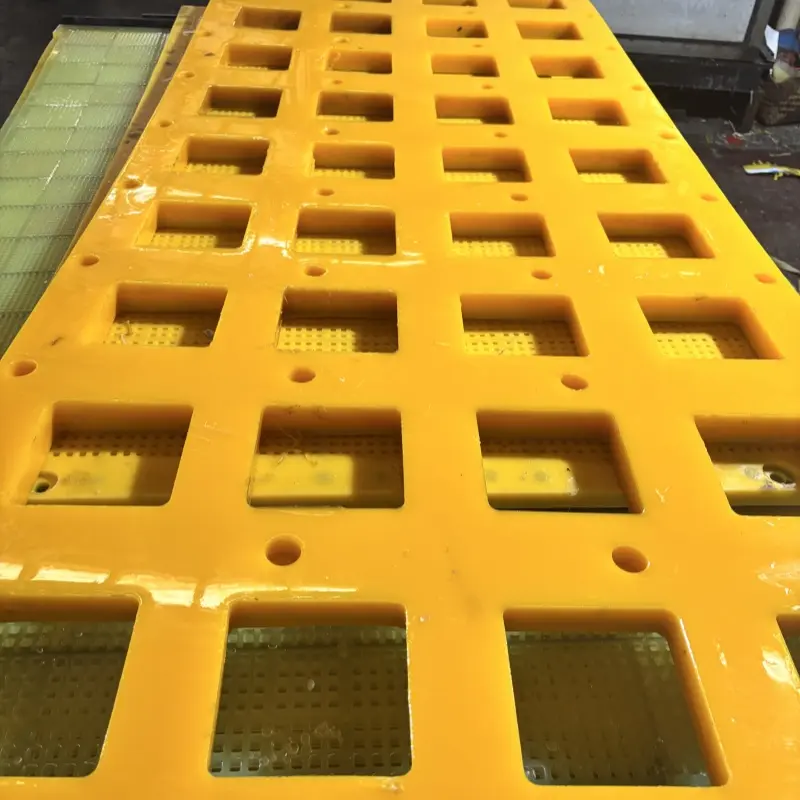

In industrial production fields such as mining, sand and gravel aggregates, polyurethane screens have become a powerful assistant in the material screening process with their excellent wear resistance, high elasticity and corrosion resistance. However, if improperly operated, even polyurethane screens with excellent performance will find it difficult to achieve their longest service life. Our Zhicheng Screen Company summarizes the experience of previous customers and professional analysis of technology, and combines scientific data to summarize the following 7 "little tricks" to extend the service life of polyurethane screens.

- 1.The installation process must be rigorous

When installing polyurethane screens, ensure that the screen surface is flat and the tension of each part is uniform. Li Gong, the technical supervisor of a large sand and gravel plant, said: "We used to have uneven force on the screen due to uneven local tightness during installation, and the screen was torn prematurely during operation." The correct approach is: install a single screen, lay the screen flat in the center of the screen frame, mark the installation hole position with a marker, and ensure that the edge of the screen exceeds the support surface of the screen frame by ≥20mm (for easy fixing).

When multiple pieces are installed, the gap between adjacent screens is ≤2mm, and the screen holes are aligned to prevent materials from getting stuck in the gap. For the installation of suspended screens, first fix the suspension device (such as wire rope or hook) at one end of the screen, adjust the horizontality of the screen, and then fix the other end to ensure that the suspension angle is consistent with the equipment design (usually 15°~30°).

- 2.Control the uniformity of feeding

Uniform feeding is the key to protecting the polyurethane screen. Sudden large load impact or concentrated accumulation of materials in a certain area of the screen will accelerate the wear of the screen. A mining company in Shandong uses automated feeding equipment to evenly disperse the materials on the screen, which extends the service life of the polyurethane screen by about 30%.

- 3.Regular cleaning and anti-blocking

Although the polyurethane screen has good self-cleaning ability, it still needs to be checked and cleaned regularly. Especially when handling wet and sticky materials, residual materials may block the screen holes and increase the operating load of the screen. It is recommended to clean the surface of the screen once every 8-10 hours of work. You can use a high-pressure water gun or special cleaning tools to maintain the permeability of the screen.

4.repair minor damage in time

During daily inspections, if small damage or cracks are found in the polyurethane screen, they should be repaired in time. If minor damage is not handled in time, it will gradually expand during the vibration of the screen. There are special polyurethane repair agents on the market. You can refer to the polyurethane screen repair technical plan and perform repair operations according to the instructions.

5. control the operating environment temperature

Polyurethane screens have certain requirements for the working environment temperature. Too high or too low temperatures will affect their performance. In a high temperature environment for a long time, polyurethane materials will accelerate aging; in a low temperature environment, the screen will become hard and brittle and easy to break. Therefore, try to control the operating environment temperature of the screen between - 20℃ and 80℃, and take insulation or cooling measures in special environments.

6. Reasonable control of vibration parameters

The vibration frequency and amplitude of the screen machine directly affect the stress of the polyurethane screen. If the vibration parameters are too large, the screen will be over-impacted; if the parameters are too small, the screening efficiency will be affected. Enterprises should determine the optimal vibration parameters through experiments based on the material characteristics and screen specifications, and regularly check the operating status of the vibration equipment.

7.Standardized shutdown and storage

When the equipment is shut down, the feeding should be stopped first, and the screen machine should be turned off after all the materials on the screen are screened to avoid the screen shutting down under load. If the polyurethane screen needs to be stored for a long time, it should be disassembled and stored in a dry, ventilated, and direct sunlight-free environment to avoid contact with sharp objects and prevent scratches on the screen surface.

Through strict control of the above 7 operating details, enterprises can not only effectively extend the service life of the polyurethane screen and reduce equipment maintenance costs, but also ensure the continuity and stability of production.

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)