01

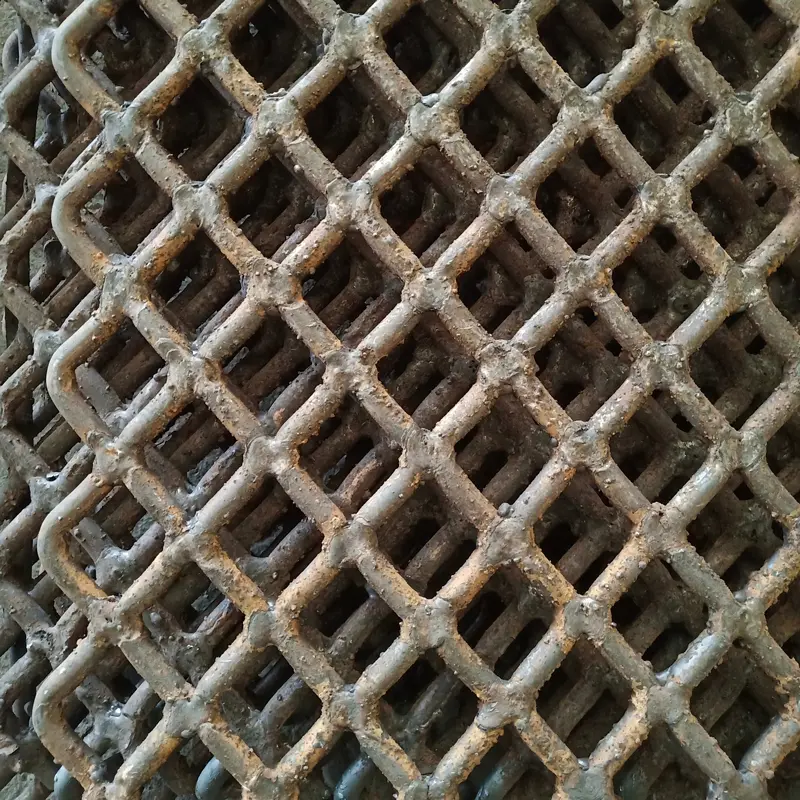

Manganese Steel Welded Mine Screen Mesh

Material Highlights

1. High-strength manganese steel: Selected high-quality manganese steel, strengthened by manganese elements, possesses high toughness and strength. In the face of frequent impacts from ores, it can maintain a stable structure better than ordinary screens, significantly extending its service life and reducing replacement costs.

2. Wear resistance upgrade: After special heat treatment, a hard and wear-resistant layer is formed on the surface of the manganese steel, effectively resisting the friction and wear of ores. When dealing with high-hardness and highly abrasive ores, its wear resistance advantage is significant, saving costs for enterprises.

Process Features

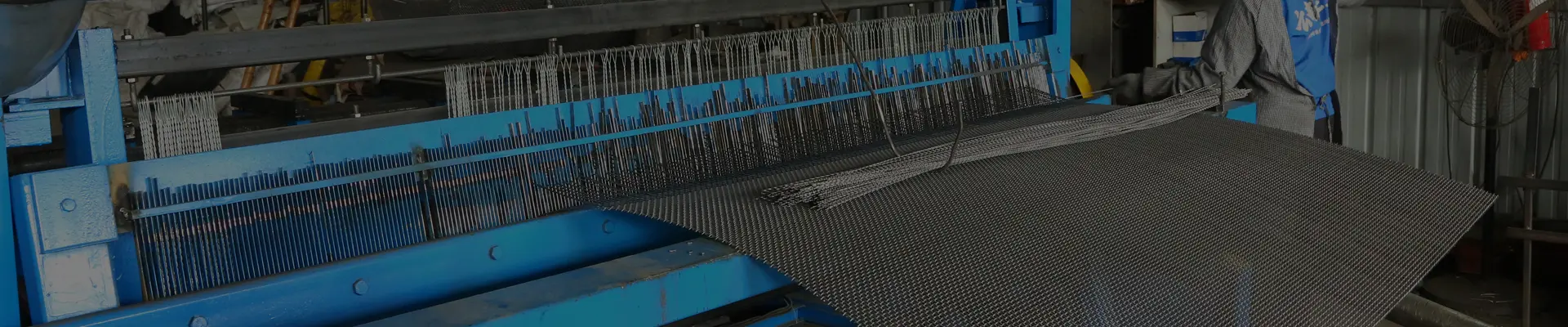

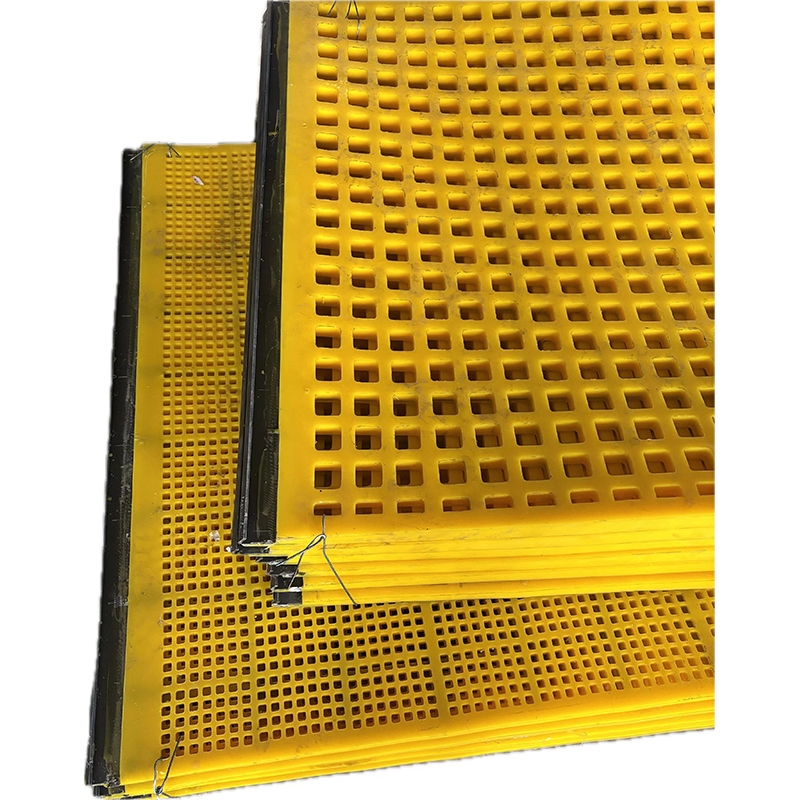

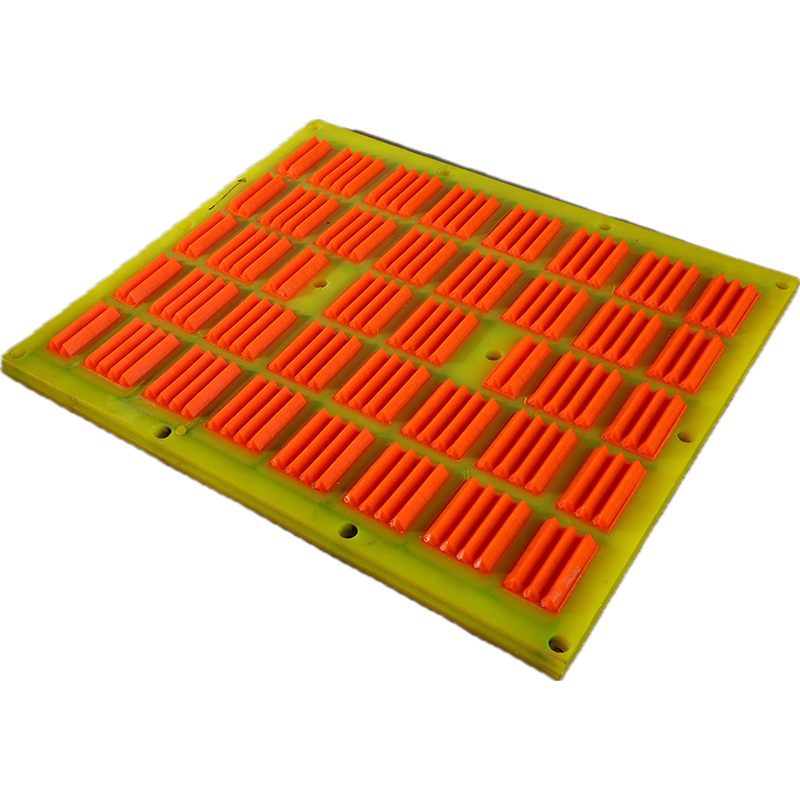

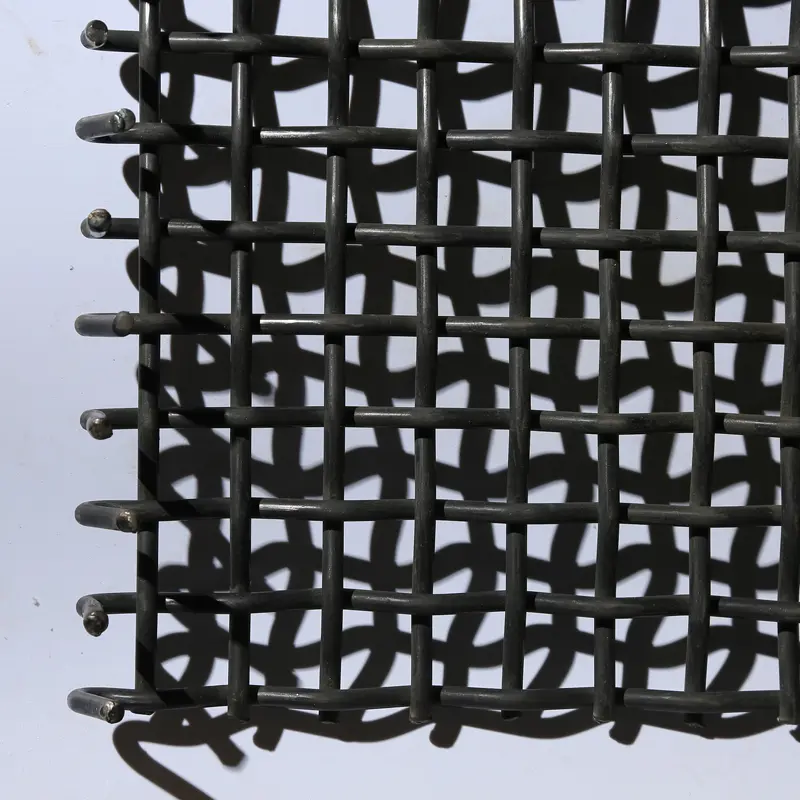

1. Rolled flower docking: The manganese steel is subjected to rolled flower treatment to increase the surface area of the screen and improve screening efficiency and strength. The subsequent docking process ensures that all parts are tightly connected and will not loosen under heavy pressure.

2. Manual welding: Each connection point is welded manually. Experienced welders adjust parameters according to the force situation to ensure firm welding points. The selected alloy welding rod is well compatible with manganese steel, and the welding points are not easy to break.

3. Heat treatment optimization: Through carefully designed heat treatment, welding internal stress is eliminated, making the screen structure uniform and dense, enhancing overall performance, and enabling stable operation in high-frequency vibration environments.

Screen Hole Design

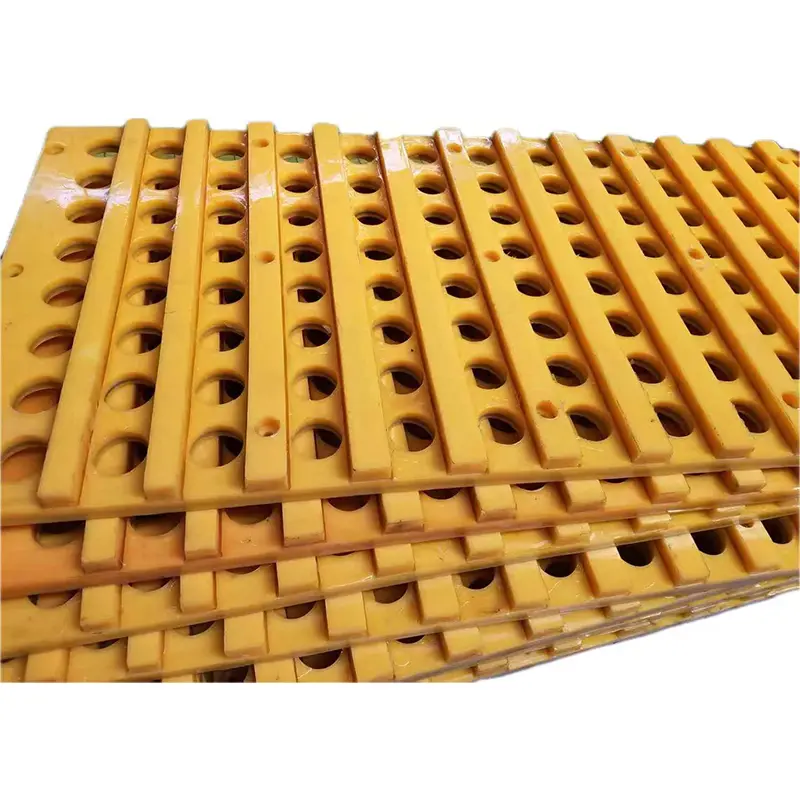

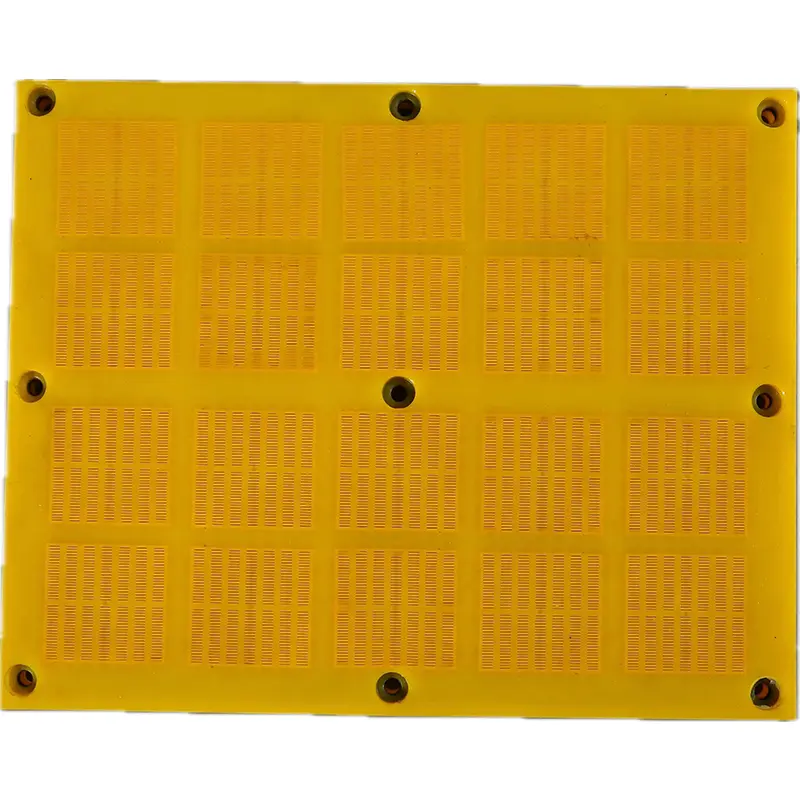

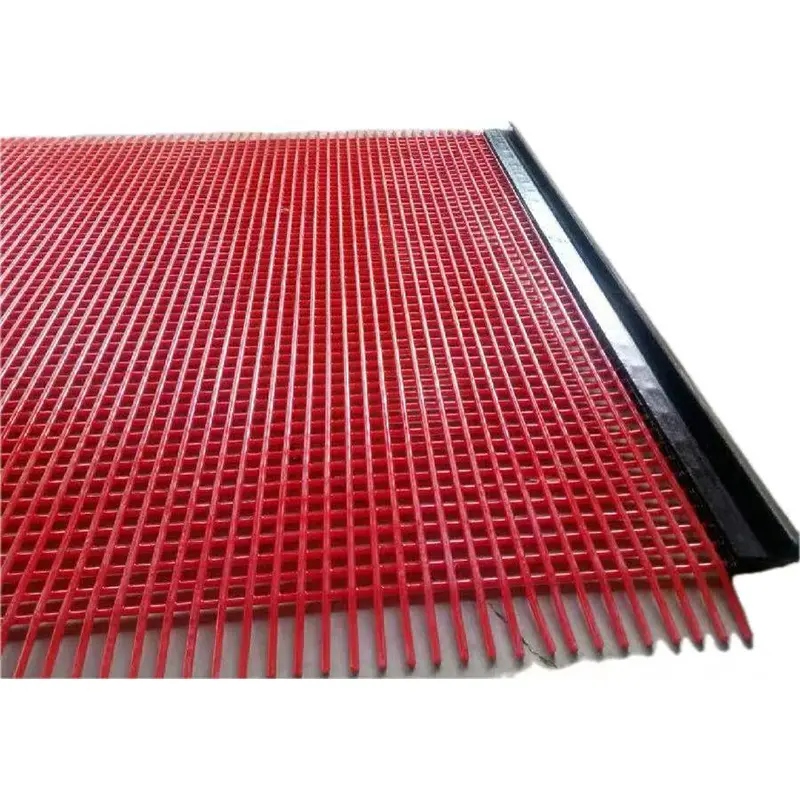

1. Various shapes: There are square holes, round holes, and diamond-shaped holes. Square holes precisely control material particle size; round holes facilitate the rapid passage of materials and reduce blockage; diamond-shaped holes balance screening efficiency and strength, suitable for large particles and strong impact materials.

2. Precise dimensions: Strictly control the size of screen holes to ensure accurate screening. In mineral processing, it can accurately classify materials according to ore characteristics, improving the efficiency and quality of mineral processing.

Performance Advantages

1. Efficient screening: Relying on reasonable screen hole design, optimized surface texture, and high-strength structure, it can quickly screen a large amount of materials, greatly improving production efficiency.

2. Long-lasting life: Combined with high-quality materials, exquisite craftsmanship, and precise heat treatment, it is more resistant to impact and friction than other screens in harsh mining environments, reducing downtime and ensuring continuous production for enterprises.

3. Easy to repair: Worn parts of the screen can be simply repaired, and partial damage does not require overall replacement, reducing usage costs and improving resource utilization.

Widely used in screening and grading equipment in various mines. In metal mines, it helps with the screening and grading of copper, iron, gold ores, etc.; in non-metallic mines such as coal mines and quartz mines, it ensures that ore particle sizes meet subsequent processing requirements, making it an ideal choice for mining screening.

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)