01

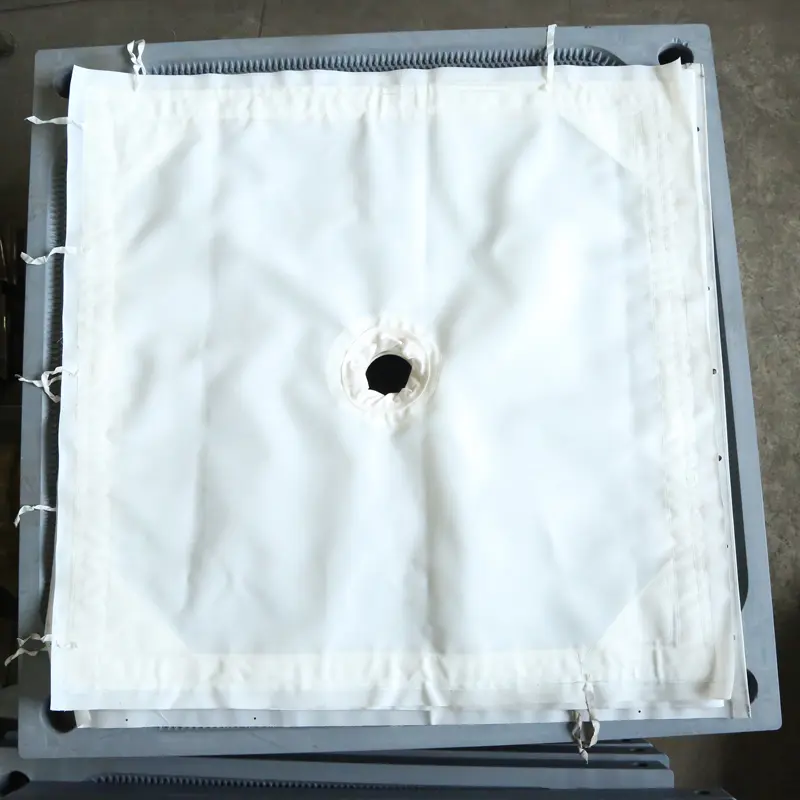

Filter Press Filter Cloth

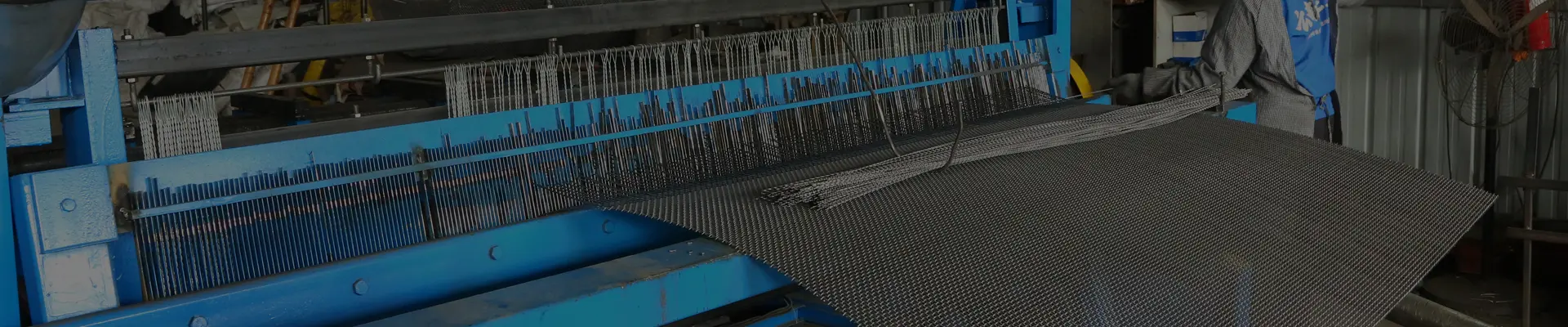

Weaving Technology Ensures Filtration Efficiency

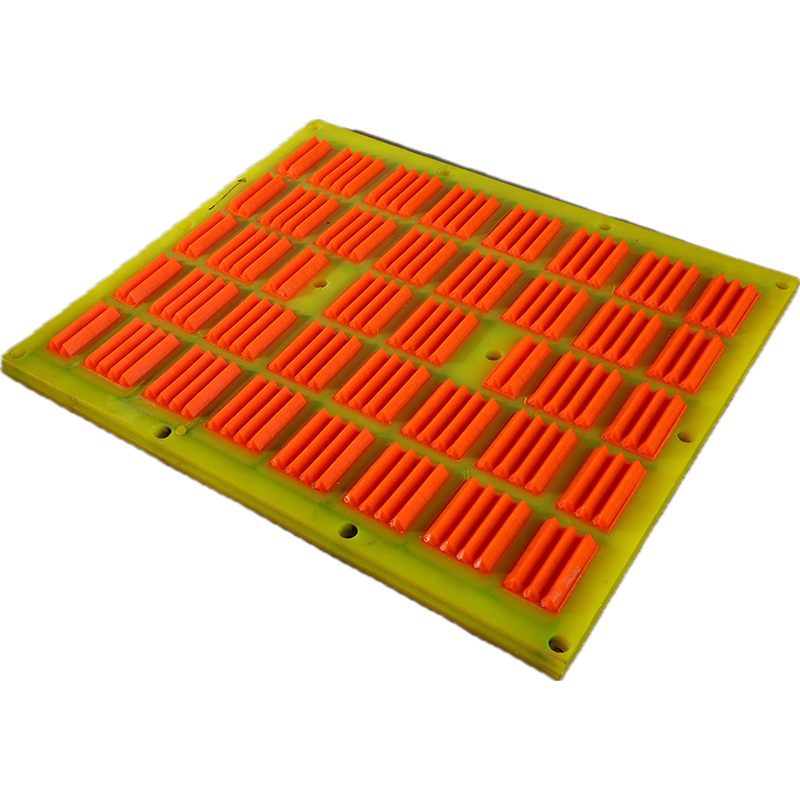

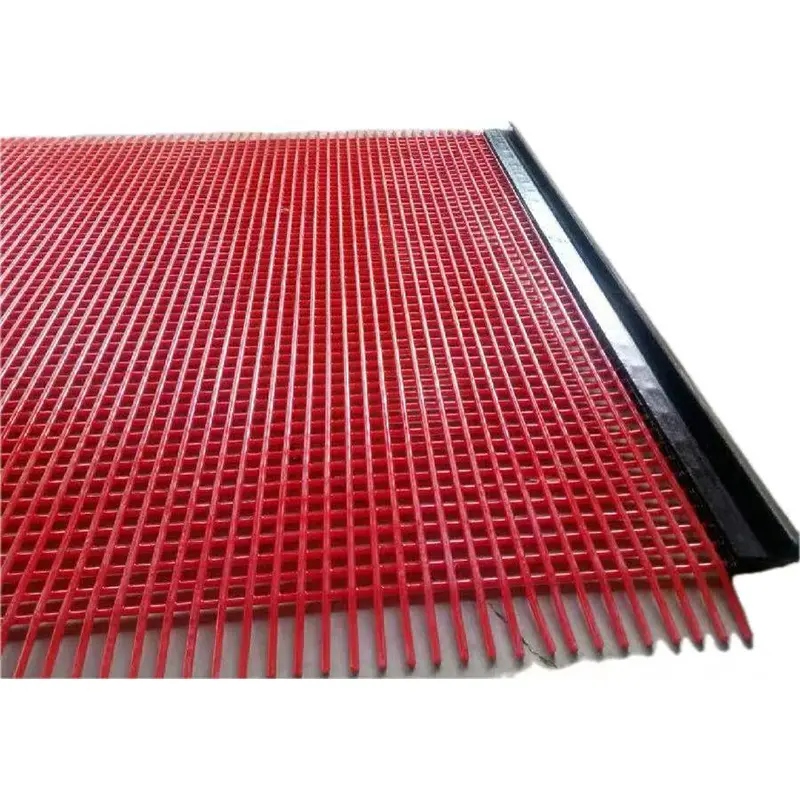

1. Plain Weave: A common weaving method where the warp and weft yarns intersect alternately. The resulting filter cloth has a smooth surface with fine and uniform mesh, high filtration precision, and is suitable for scenarios requiring extremely high purity of the filtrate, such as high-purity liquid filtration in the electronics industry. It can accurately intercept tiny impurities, ensuring product quality is not contaminated.

2. Twill Weave: Two warp yarns intersect with two weft yarns, forming a diamond-shaped mesh. The structure is denser and stronger than plain weave. It has obvious advantages when dealing with materials containing larger particles and requiring certain filtration precision, such as the filtration of concrete admixture raw materials in the building materials industry.

3. Satin Weave: Either the warp or weft yarns float on the surface of the fabric with fewer intersection points. This makes the filter cloth surface smooth and less prone to clogging, allowing the filtrate to flow smoothly. When processing materials with high viscosity, it can effectively prevent material adhesion and improve filtration efficiency, commonly used in the food processing industry for filtering starch, colloids, and other materials.

Excellent Performance Highlights Advantages

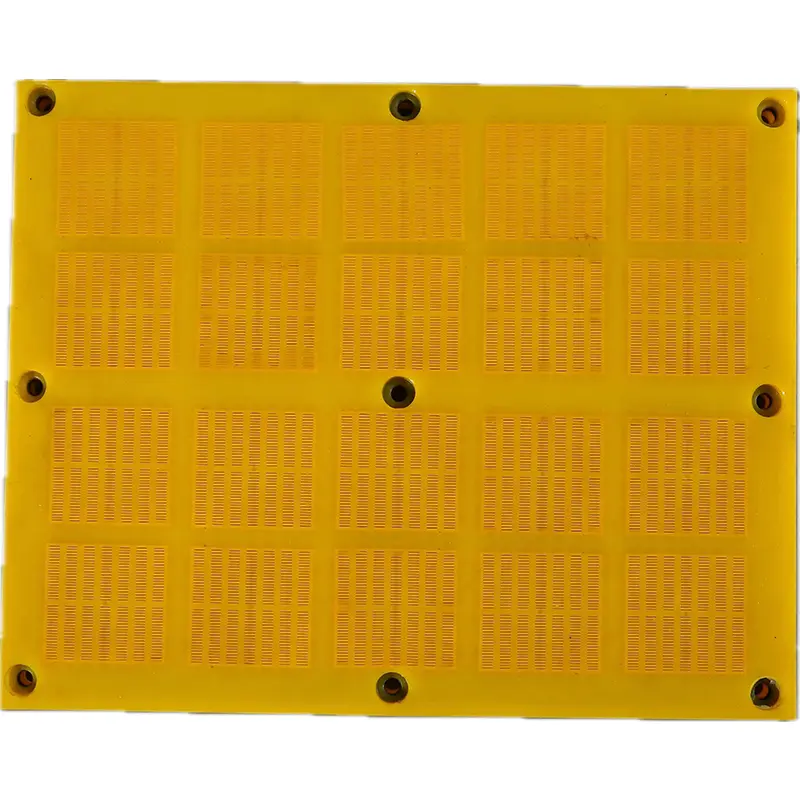

1. High Filtration Precision: Through precise control of materials and weaving technology, filter cloths for filter presses can achieve high-precision filtration, intercepting particles from microns to millimeters as required. In the pharmaceutical industry, it can effectively remove impurities from drug raw materials, ensuring the safety and effectiveness of drugs.

2. Good Air Permeability: Well-designed quality filter cloths, while ensuring filtration precision, have a fiber structure and mesh distribution that facilitate rapid liquid penetration, reducing filtration time. In sewage treatment, a large amount of sewage needs to be processed quickly, and good air permeability helps the filter cloth complete tasks efficiently.

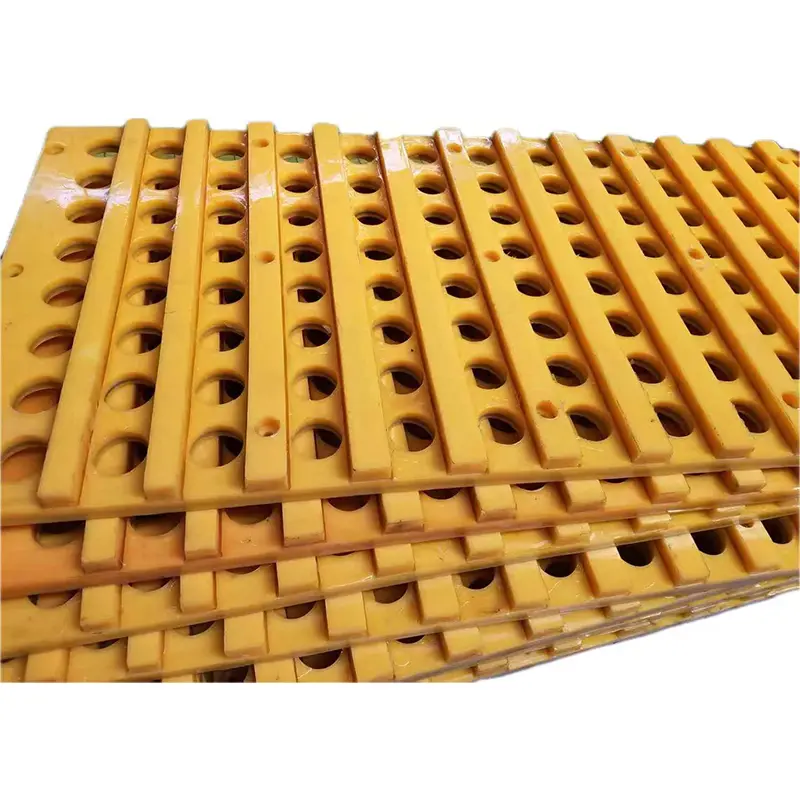

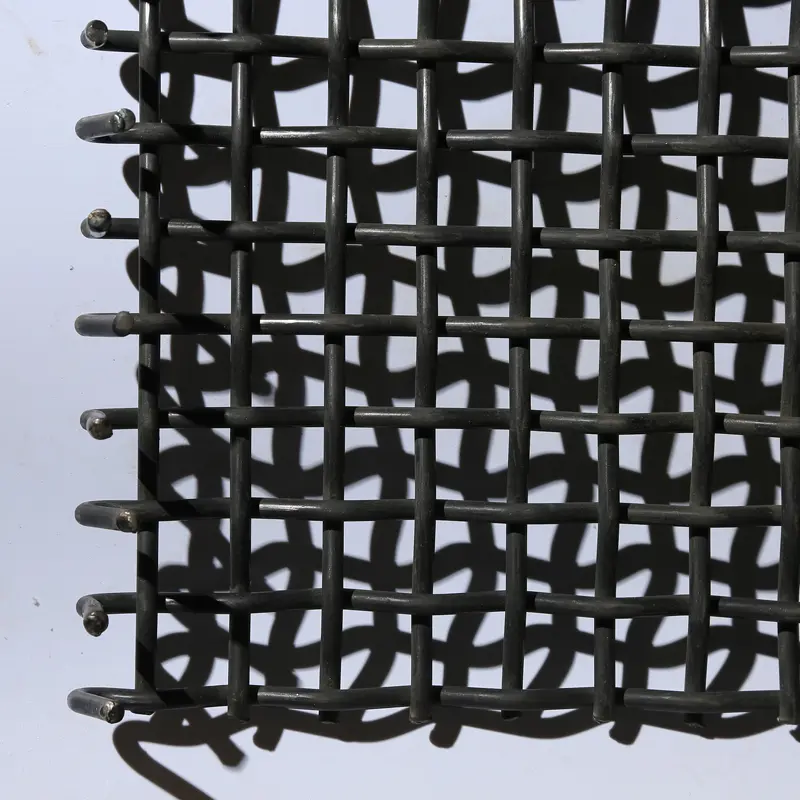

3. Outstanding Abrasion Resistance: Using high-strength fiber materials and optimizing weaving technology, the filter cloth has excellent abrasion resistance. In industries such as mining and building materials that frequently handle hard materials like sand and ore, it can withstand long-term friction, extend service life, and reduce replacement costs.

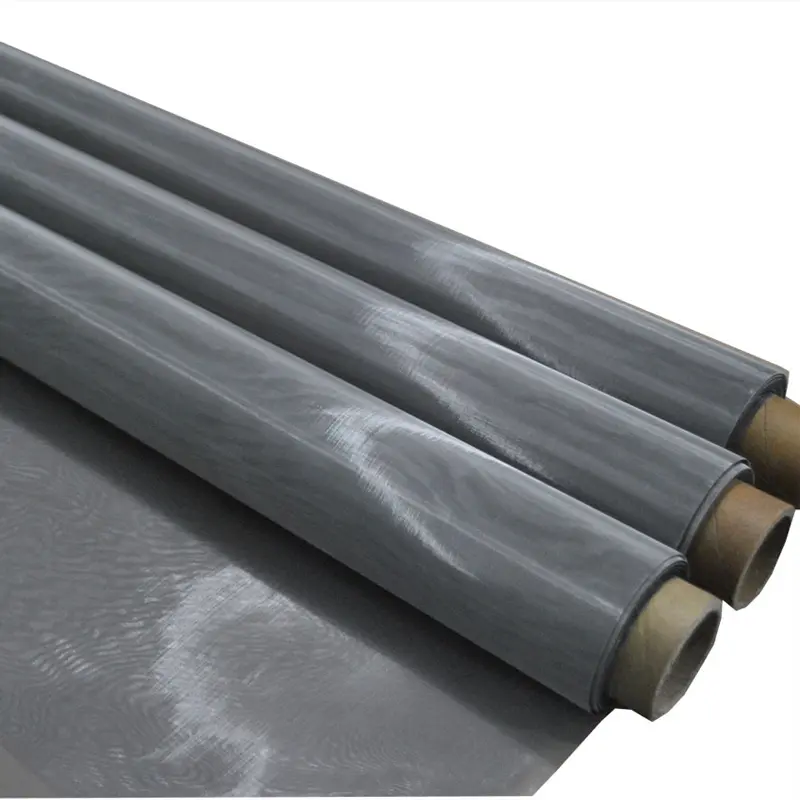

4. Chemical Corrosion Resistance: Depending on the application scenario, filter cloths are made of corresponding corrosion-resistant materials. For example, polypropylene fiber filter cloths are used in environments with strong acid and alkali resistance, and metal fiber filter cloths are used in extremely corrosion-resistant special conditions, ensuring stable operation in complex chemical environments.

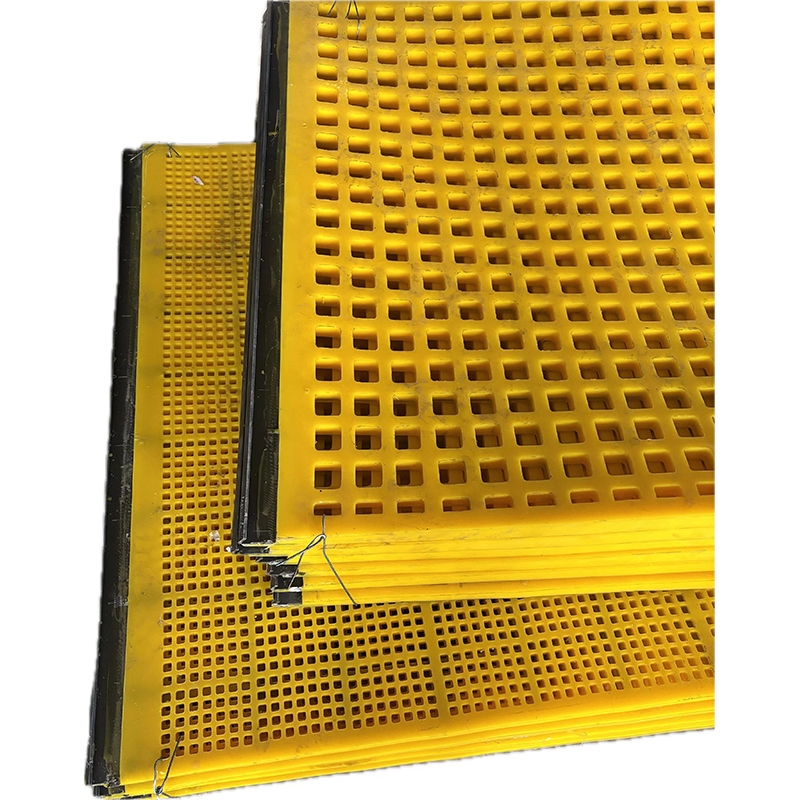

Wide Application Helps Multiple Industries

1. Mining: Used for tailings dewatering, concentrate filtration, recycling water resources, reducing tailings discharge, and improving the utilization rate of mineral resources.

2. Environmental Protection: Sewage treatment plants use it for deep sewage treatment, removing moisture from sludge; in landfill leachate treatment, ensuring leachate meets discharge standards.

3. Chemical Industry: In chemical production, according to chemical characteristics and filtration requirements, it achieves efficient solid-liquid separation of reaction products and intermediate products.

Filter cloths for filter presses, with diverse materials, exquisite craftsmanship, outstanding performance, and wide applications, have become key components in industrial production, providing strong support for the sustainable development of various industries.

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)