No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

In the rapidly evolving landscape of filtration and separation industries, the use of Fine Mesh Metals has emerged as a game-changer, offering unparalleled efficiency and performance. According to a recent report by MarketsandMarkets, the global filtration market is projected to reach $45.73 billion by 2025, driven by increasing demands for enhanced liquid and air purification systems. Fine Mesh Metals, with their superior strength and durability, are becoming integral to applications ranging from food processing to pharmaceuticals. As industries face stringent regulatory requirements and a relentless push for higher quality standards, the adoption of advanced filtration solutions utilizing Fine Mesh Metals is no longer an option but a necessity. This guide aims to explore the capabilities, benefits, and innovative applications of Fine Mesh Metals, equipping professionals with essential tips for optimizing filtration and separation processes in their operations.

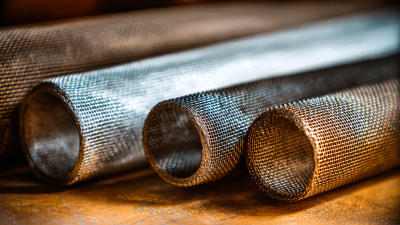

Fine mesh metals play a crucial role in revolutionizing modern filtration technologies, providing innovative solutions that enhance both efficiency and effectiveness in various industries. These materials, known for their precise pore sizes and high strength, enable the separation of particles at a microscopic level, making them invaluable in sectors such as pharmaceuticals, food processing, and wastewater treatment. The ability to filter out contaminants while maintaining the integrity of the material being processed ensures higher product quality and safety standards.

Furthermore, the versatility of fine mesh metals allows for customization according to specific filtration needs. Techniques such as welding and weaving can produce mesh with varying degrees of porosity, catering to different applications. This adaptability not only improves the functional lifespan of filtration systems but also reduces maintenance costs and operational downtime. With advancements in technology, the integration of fine mesh metals is paving the way for more sustainable and efficient practices across multiple industries, highlighting their importance in the future of filtration and separation processes.

In the filtration and separation industries, fine mesh metals have emerged as a crucial component, enhancing efficiency and effectiveness across various applications. A report by the Global Filtration Market predicts that the industry will reach $43.61 billion by 2027, driven primarily by innovations in filtration technology. Fine mesh metals provide unparalleled strength and flexibility, enabling precise separation of materials down to micrometer levels. This capability is especially vital in industries such as pharmaceuticals, where even the slightest impurity can compromise product integrity.

One of the standout benefits of using fine mesh metals is their high resistance to corrosion and wear. According to a study published in the Journal of Separation Science, fine mesh materials not only improve the lifetime of filtration systems but also reduce maintenance costs by up to 30%. Additionally, these metals facilitate a higher flow rate compared to traditional separation methods, resulting in increased productivity. As industries continue to demand higher purity and efficiency, the adoption of fine mesh metals will play a significant role in meeting these challenges and advancing separation technology.

The filtration industry is currently witnessing a remarkable growth trajectory, particularly in the fine mesh metals segment. The global expanded metal foils market is projected to reach a significant USD 4.10 billion by 2034, rising from USD 2.64 billion in 2024. This growth can be attributed to the increasing demand for high-performance filtration solutions across various sectors, including chemicals and petrochemicals. As industries strive for efficiency and reliability, the need for durable and effective filtration systems becomes paramount.

Furthermore, the wire mesh market is forecasted to grow from USD 8.48 billion in 2025 to USD 11.70 billion by 2034, with a steady CAGR of 3.64% during this period. This trend underscores the expanding applications of fine mesh technologies in diverse fields, particularly those that require stringent separation and filtration capabilities. Innovations, such as advanced sieve and mesh products, are enhancing operational efficiencies, making them essential components in processes involving powdered metals and hazardous substances. The continued development in fine mesh metals will undoubtedly lead to transformative improvements within the filtration and separation industries.

Fine mesh metals have become indispensable in various industries, enhancing filtration and separation processes significantly. In the pharmaceutical sector, for example, a study by MarketsandMarkets estimates that the global filtration market will reach $36.1 billion by 2025, with fine mesh technologies at the forefront due to their ability to remove contaminants from drugs and ensure compliance with stringent regulatory standards. Companies utilizing fine mesh filters have reported purification rates above 99%, showcasing their effectiveness in producing high-quality pharmaceutical products.

In the food and beverage industry, fine mesh metals are employed to ensure product safety and quality. The Institute of Food Technologists reports that using fine mesh filtration can reduce the presence of unwanted particles by over 95%, which is crucial for maintaining the integrity of food products. For instance, a prominent beverage manufacturer adopted fine mesh screens in their production lines, resulting in a 20% reduction in waste caused by contamination. This case not only illustrates the efficiency of fine mesh metals but also highlights their role in cost-effective manufacturing processes across different sectors.

As industries continue to seek enhanced efficiency in filtration and separation processes, advancements in fine mesh metal technologies are becoming increasingly crucial. The integration of AI-driven hyper-personalization and predictive analytics is poised to revolutionize how companies approach filtration systems. According to a recent industry report, the global filtration market is expected to reach USD 36.9 billion by 2025, showcasing a robust growth trajectory driven by these technological innovations. Fine mesh metals play a pivotal role in improving filtration precision and ensuring consistent quality across various applications.

Moreover, the incorporation of advanced spectroscopic techniques with AI analysis is transforming food safety and quality control measures. A study indicated that the use of AI in spectroscopy can enhance detection accuracy by up to 80%, allowing for real-time monitoring and instant response to quality deviations. As future technologies like 5G and machine learning continue to evolve, the potential for fine mesh metal applications in these fields becomes even more significant, paving the way for novel solutions that enhance operational efficiency across industries.