No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

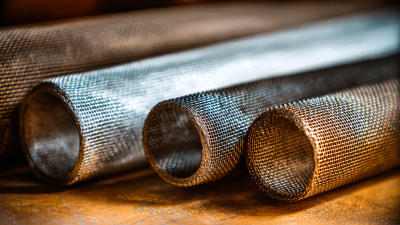

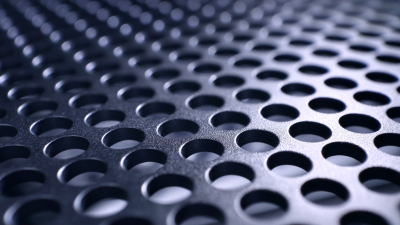

In industrial applications, the use of Fine Mesh Screens has become increasingly prevalent, addressing various filtration and separation needs across multiple sectors. According to a recent industry analysis by MarketsandMarkets, the global filtration market is projected to reach $120 billion by 2026, driven by advancements in filtration technologies and rising demand for efficient industrial processes.

However, despite their effectiveness, Fine Mesh Screens are not without challenges. Common issues such as clogging, durability under high pressure, and maintenance requirements can significantly impact operational efficiency. Understanding these problems is crucial for industries that rely on precise filtration methods, particularly in sectors like food and beverage, pharmaceuticals, and chemical processing, where compliance and quality control are paramount.

This blog will explore the common issues encountered with Fine Mesh Screens and provide insights into solutions to enhance their performance in demanding industrial environments.

Fine mesh screens are essential components in many industrial processes, filtering particles and ensuring product quality. However, users often encounter common problems that can hinder efficiency and productivity. One significant issue is clogging, which can occur when particles larger than the mesh size accumulate, reducing airflow and flow rates. This not only impacts production efficiency but also leads to increased maintenance costs. Regular monitoring and cleaning of the screens can mitigate this issue, but it requires time and resources that could be better utilized elsewhere.

Another common challenge is wear and tear. Fine mesh screens are typically subjected to harsh operating conditions, including high pressures and abrasive materials. Over time, this can lead to the deterioration of the screen integrity, resulting in premature failures and potential system breakdowns. Implementing advanced predictive maintenance strategies, aided by AI technologies, could improve the lifespan of these screens by allowing for proactive replacements before significant damage occurs. As industries evolve and become more tech-driven, incorporating such solutions is vital to overcoming these challenges and enhancing operational efficiency.

Fine mesh screens are critical in various industrial applications, but they often face issues that lead to damage and wear. One of the primary factors contributing to mesh screen deterioration is erosion caused by high-speed sand movement, particularly in environments like deepwater gas wells. The accelerated flow of sand, combined with corrosive elements in the gas, can result in significant erosion of sand control screens. Recent studies highlight that such erosion can lead to catastrophic completion failures and considerable production losses, emphasizing the need for durable filtration solutions.

To mitigate these risks, it is essential to consider the materials and design of fine mesh screens. Utilizing advanced materials that can withstand both mechanical wear and corrosive environments is crucial. Moreover, optimizing screen design to reduce exposure to high-velocity sand flow can significantly extend operational life. Implementing regular maintenance checks and monitoring erosion patterns can also help in identifying potential issues before they escalate.

Tips: Always choose screens made from corrosion-resistant materials when working in harsh environments. Regular inspections can reveal early signs of wear, allowing for timely replacements and minimizing downtime. Additionally, investing in advanced modeling and simulation technologies can aid in predicting the lifespan of mesh screens, leading to more strategic maintenance planning.

Fine mesh screens, often utilized in various industrial applications, are prone to a set of common issues that can significantly affect their performance and longevity. To combat these challenges, implementing preventive measures is essential for extending the lifespan of these screens. Regular inspections should be carried out to identify wear and tear, particularly in high-traffic environments where they are subjected to consistent stress. Addressing issues such as clogs due to particulates or chemical corrosion early on can prevent more significant damage from occurring.

In addition to routine inspections, proper maintenance practices can significantly enhance screen durability. Cleaning methods should be tailored to the specific materials being filtered, as harsh cleaning agents can sometimes cause more harm than good. Employing appropriate storage techniques when the screens are not in use is equally important; exposure to moisture or extreme temperatures can weaken the mesh integrity. By adopting these preventive measures, industries can not only improve the operational efficiency of their fine mesh screens but also reduce the frequency of replacement, ultimately leading to cost savings and better resource management.

This bar chart illustrates the common issues faced with fine mesh screens in various industrial applications, along with their estimated impact on operation efficiency.

When working with fine mesh screens in industrial applications, operators often face several challenges that can hinder performance. One common issue is clogging, which can significantly reduce throughput and efficiency. To combat this, regular maintenance and inspection are essential. Cleaning the screens at scheduled intervals helps to prevent buildup of particles and ensures consistent flow. Additionally, implementing a shake or vibration mechanism can help dislodge any trapped materials, improving the screen's operational reliability.

Another frequent problem is wear and tear due to abrasive materials. Utilizing screens made of more durable materials can mitigate this issue significantly. Operators should also pay attention to the installation process; ensuring that the mesh is appropriately tensioned can reduce the likelihood of damage during operation. Moreover, monitoring the feed rate can help balance the load on the screen, preventing unnecessary stress. Adjusting these variables not only enhances screen performance but can also prolong the lifespan of the mesh, ultimately leading to more efficient production processes.

Regular maintenance and inspection of fine mesh screens are critical in industrial applications to ensure operational efficiency and product quality. According to a recent report by the Industrial Fabric Association International (IFAI), nearly 20% of production downtime is attributed to screen-related failures, underscoring the importance of a robust maintenance strategy. Implementing a routine inspection schedule allows operators to identify wear and tear before it leads to production halts. Inspections should focus on checking for physical damage, blockage, and the integrity of mesh tension, as these factors significantly affect the screen's performance.

In addition to inspections, adhering to best practices during maintenance can extend the lifespan of fine mesh screens. The Conveyor Equipment Manufacturers Association (CEMA) notes that screens that undergo regular cleaning and surface treatment can enhance both their durability and filtration efficiency by up to 30%. Proper documentation of maintenance activities is also crucial; maintenance logs can reveal patterns that inform better operational decisions. By combining these practices, companies can minimize unexpected breakdowns and maximize throughput, ultimately translating into substantial cost savings in the long run.

| Issue | Description | Best Practices | Frequency of Inspection |

|---|---|---|---|

| Clogging | Build-up of debris or particles on the screen surface. | Regular cleaning with appropriate solvents or methods. | Weekly |

| Tear or Rip | Physical damage due to over-stress or impact. | Inspect for wear and replace if necessary. | Monthly |

| Corrosion | Degradation due to exposure to chemicals or moisture. | Use corrosion-resistant materials and regular washdowns. | Monthly |

| Misalignment | Improper positioning affecting the screen's performance. | Regular checks on installation alignment and adjustment. | Bi-weekly |

| Wear and Tear | Natural degradation of materials over time. | Scheduled replacement based on usage cycles. | Quarterly |