No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

The use of Fine Mesh Metals has become increasingly critical across various industries, serving a multitude of functions that enhance product quality and operational efficiency. According to a report by Grand View Research, the global market for fine mesh screen materials is projected to reach over $4 billion by 2026, driven by their versatile applications in sectors such as pharmaceuticals, food processing, and water filtration. As industries strive for higher standards of precision and safety, the demand for these materials will continue to escalate.

Industry expert Dr. Emily Carter, a leading figure in materials science, emphasizes the significance of Fine Mesh Metals by stating, "The precision and reliability of fine mesh metals are indispensable for industries that require meticulous filtration and separation processes." Her insights highlight how these materials not only enhance product performance but also contribute to sustainability efforts by minimizing waste and ensuring resource efficiency. By exploring the top 10 benefits of Fine Mesh Metals in this article, we will uncover how these innovations are reshaping manufacturing processes and driving growth in diverse sectors.

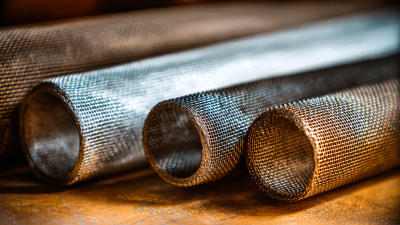

Fine mesh metals have gained significant traction across various industries due to their remarkable versatility and functionality. These intricate materials, often made from metals such as stainless steel, aluminum, or copper, are engineered to allow for precise filtration and screening processes. In the food and beverage sector, fine mesh metals are employed in filtration systems to ensure purity and quality in production, while also allowing for increased efficiency and reduced waste. Their ability to withstand high temperatures and corrosive environments makes them indispensable in chemical processing and pharmaceutical applications.

Moreover, the use of fine mesh metals extends into the realm of construction and architecture, where they serve not only practical purposes but also aesthetic ones. Architects and designers leverage these materials to create innovative facades and safety screens, providing both durability and an appealing visual aspect. In electronics, fine mesh metals are utilized in shielding to protect sensitive components from electromagnetic interference, showcasing their essential role in modern manufacturing processes. The diverse applications of fine mesh metals highlight their importance in promoting safety, efficiency, and sustainability across various industries.

This chart illustrates the top ten benefits of utilizing fine mesh metals across various industries, showcasing their versatility and application. The benefits are quantified based on industry relevance and application frequency.

Fine mesh metals have become essential in various industries due to their remarkable ability to enhance filtration efficiency. According to a recent market report by Grand View Research, the filtration market is expected to reach $63.6 billion by 2025, driven by the growing need for cleaner air and water in industrial applications. Fine mesh metals, with their precise openings, allow for effective separation of particles from liquids and gases, significantly improving the quality of the output.

In the food and beverage industry, for instance, the use of fine mesh metal filters has been linked to a marked increase in product purity. A study by the Institute of Food Technologists indicates that employing high-quality mesh filters can reduce contaminants by up to 99%, ensuring safer products for consumers. Similarly, in the pharmaceutical sector, fine mesh metals are crucial in processing active ingredients; they help maintain stringent compliance with industry standards while enhancing overall efficiency. As these industries continue to evolve, the integration of fine mesh metals in filtration processes stands out as a key strategy for meeting regulatory demands and achieving operational excellence.

Fine mesh metals have emerged as a highly cost-effective solution across various industries, significantly reducing operational expenses and enhancing overall productivity. According to a report from Smithers Pira, the global market for mesh filter products is projected to reach $7.3 billion by 2026, reflecting the growing demand and versatility of these materials. Industries such as food processing, pharmaceuticals, and water treatment are increasingly choosing fine mesh metals due to their durability and efficiency, resulting in lower maintenance costs and reduced material waste during production processes.

One of the primary financial advantages of using fine mesh metals lies in their longevity and resistance to wear and tear. A study by the Metal Powder Industries Federation highlights that using high-quality fine mesh metals can extend the lifespan of equipment by up to 50%. This reduction in replacements and repairs translates to significant savings over time. Furthermore, the ability of fine mesh metals to achieve finer filtration can lead to higher product quality, allowing manufacturers to comply with regulatory standards more effectively, which can avert potential fines and improve market competitiveness. As industries continue to recognize these benefits, the adoption of fine mesh metals is expected to grow, paving the way for more sustainable and economical production practices.

Fine mesh metals have emerged as critical components across numerous industries, significantly enhancing safety standards in various applications. Their design, characterized by a network of tiny openings, provides superior filtration, thereby preventing contaminants from entering sensitive environments. In fields such as food processing, pharmaceuticals, and aerospace, fine mesh metals are indispensable for ensuring that only the highest quality materials come into contact with end products, reducing the risk of contamination and thereby protecting public health.

Moreover, the lightweight and robust nature of fine mesh metals contributes to improved safety in manufacturing processes. For instance, in the automotive industry, using fine mesh materials can reduce the weight of components without compromising structural integrity, leading to safer vehicles with better fuel efficiency. Additionally, these metals can be utilized in protective equipment and safety barriers, creating a safer workspace by minimizing exposure to hazardous materials and reducing the likelihood of accidents. By integrating fine mesh metals, companies can not only adhere to safety regulations but also foster a culture of responsibility towards employee and consumer safety.

Fine mesh metals have emerged as a transformative material in various innovative sectors, particularly in emerging technologies. Their unique properties, such as high permeability and strength, make them ideal for applications in filtration and separation processes. For instance, the aerospace industry utilizes fine mesh metals in fuel filtration systems, enhancing efficiency and safety by ensuring contaminants are removed at micro levels.

Additionally, the medical field has begun to leverage fine mesh metals in the development of advanced medical devices. Their excellent biocompatibility and structural integrity allow for the creation of intricate scaffolds used in tissue engineering, promoting cell growth and healing. Moreover, in the realm of renewable energy, fine mesh metals are used in solar panels to improve light absorption and energy conversion rates, driving the shift towards more sustainable energy solutions. As technology continues to evolve, the applications of fine mesh metals are set to expand, revolutionizing traditional processes across various industries.

| Benefit | Industry Application | Description |

|---|---|---|

| Enhanced Filtration | Water Treatment | Fine mesh metals improve the efficiency of water filtration systems by removing smaller particles. |

| High Strength-to-Weight Ratio | Aerospace | Offers significant weight savings while maintaining structural integrity in aircraft components. |

| Corrosion Resistance | Chemical Processing | Fine mesh metals are less likely to corrode in harsh chemical environments, extending equipment life. |

| Customizable Designs | Manufacturing | Flexibility to create tailored mesh designs for specific applications in production lines. |

| Improved Airflow | HVAC Systems | Provides better air circulation and filtration in heating and cooling systems. |

| Heat Resistance | Automotive | Can withstand high temperatures, making them ideal for use in engine components. |

| Sustainability | Recycling | Recyclable materials contribute to reduced environmental impact. |

| Enhanced Safety | Food Processing | Minimizes contamination risks through effective filtration of food products. |

| Electromagnetic Shielding | Telecommunications | Used in components to protect sensitive equipment from electromagnetic interference. |

| Aesthetic Appeal | Architecture | Fine mesh metals are often used in modern designs for visual texture and light control. |