No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

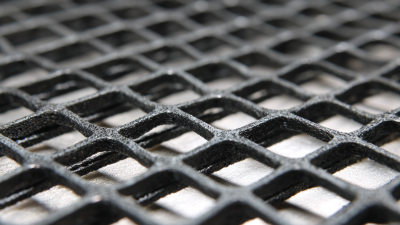

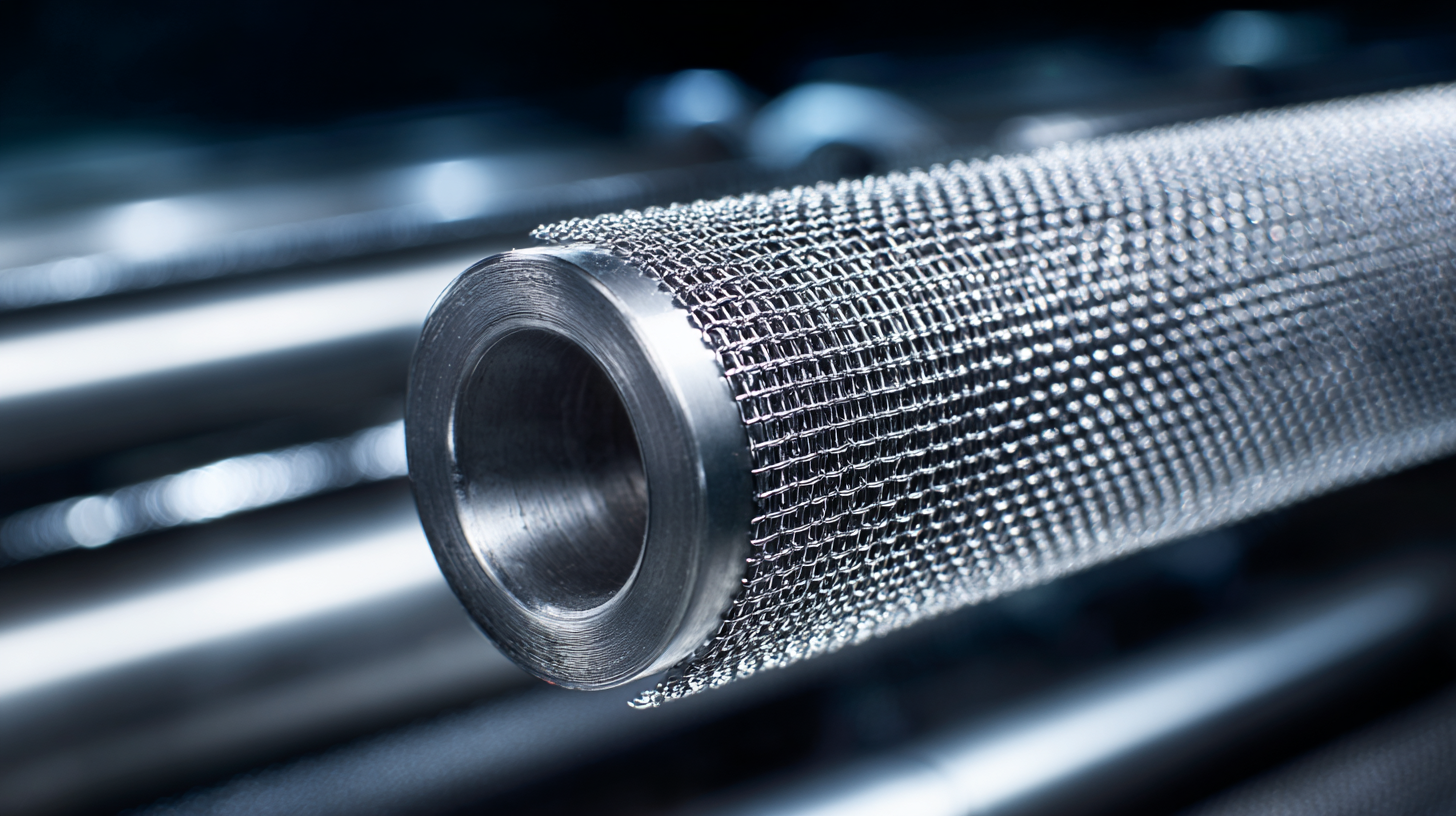

In the evolving landscape of industrial filtration, the introduction of innovative materials has revolutionized the effectiveness and efficiency of filtration solutions. One such material making significant strides is Urethane Screen Mesh. Renowned for its durability and versatility, Urethane Screen Mesh offers a distinctive advantage over traditional filtration media, facilitating enhanced performance across a variety of applications. Its unique composition not only provides superior resistance to wear and tear but also ensures a consistent filtration rate, reducing downtime and maintenance costs. This article delves into the myriad benefits of Urethane Screen Mesh, exploring its impact on filtration technology and how it addresses the challenges faced by industries today. By understanding the critical role that Urethane Screen Mesh plays in modern filtration solutions, we can appreciate its value in optimizing processes and improving product quality in diverse sectors.

Urethane screen mesh has emerged as a transformative solution in modern filtration processes, offering numerous advantages over traditional materials. According to a recent report by the Filtration Society, urethane meshes can achieve filtration efficiencies exceeding 95%, significantly improving the overall quality of filtered substances. This high efficiency is primarily due to urethane’s superior elasticity and durability, which allow for consistent performance across various applications, from water treatment to industrial processes.

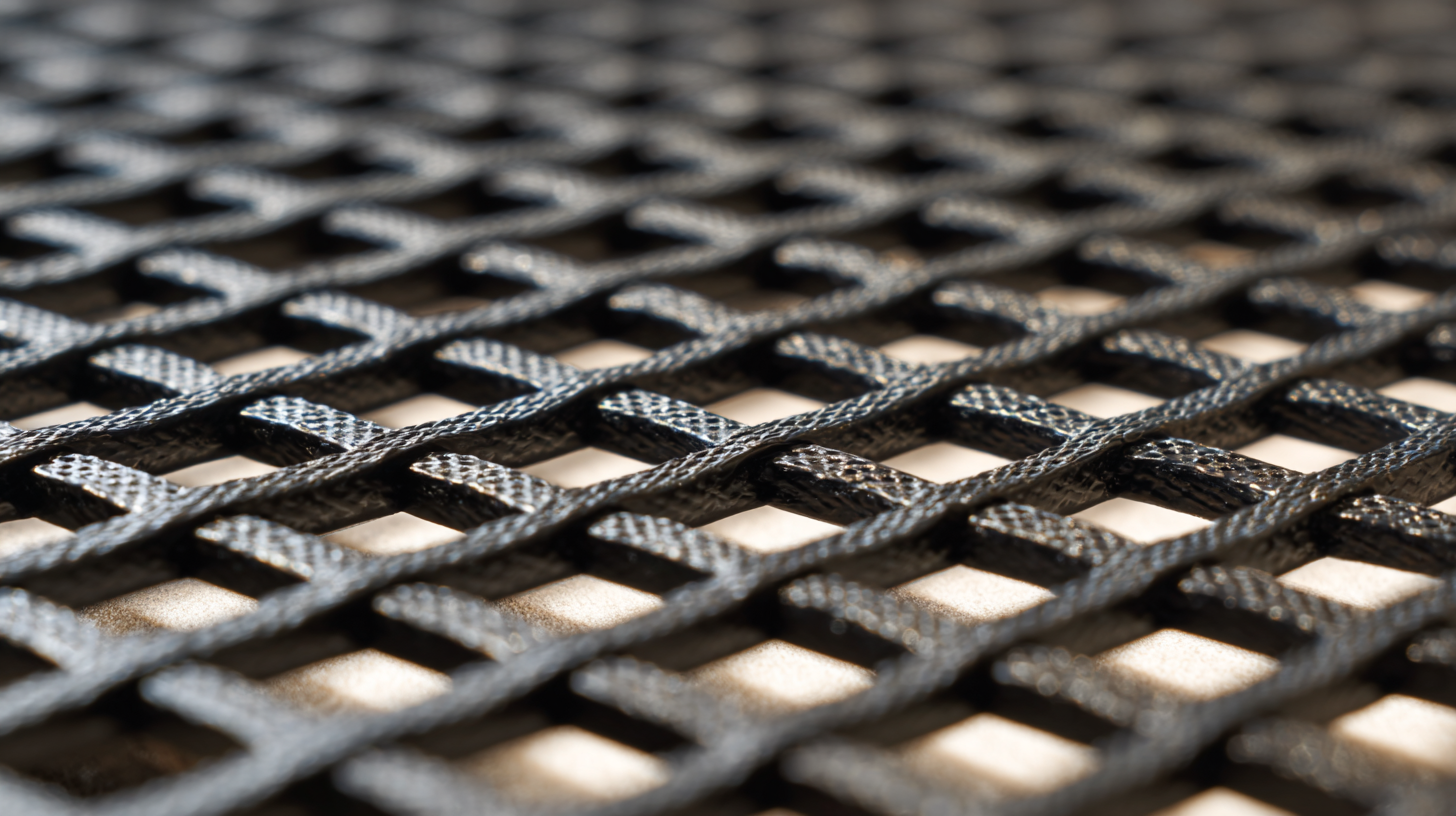

Furthermore, urethane screen mesh demonstrates remarkable resistance to chemical degradation and abrasion. The U.S. filtration market is projected to grow at a CAGR of 6.5% through 2025, driven by the demand for durable filtration solutions. Urethane’s ability to withstand harsh chemicals and mechanical wear makes it an ideal choice for industries that require long-lasting and reliable filters. With their excellent fine particle retention and easy cleaning properties, urethane screen meshes not only enhance filtration processes but also contribute to reduced operational costs by minimizing downtime and replacement frequency.

Urethane screen mesh has emerged as a robust alternative in modern filtration solutions, particularly when compared to traditional materials such as metal and nylon. One of the primary performance indicators is the resistance to wear and tear. Urethane mesh offers superior durability and longevity, significantly reducing the frequency of replacements required. This resilience not only translates into cost savings over time but also minimizes downtime in operations, making it an efficient choice for industries reliant on consistent filtration processes.

Urethane screen mesh has emerged as a robust alternative in modern filtration solutions, particularly when compared to traditional materials such as metal and nylon. One of the primary performance indicators is the resistance to wear and tear. Urethane mesh offers superior durability and longevity, significantly reducing the frequency of replacements required. This resilience not only translates into cost savings over time but also minimizes downtime in operations, making it an efficient choice for industries reliant on consistent filtration processes.

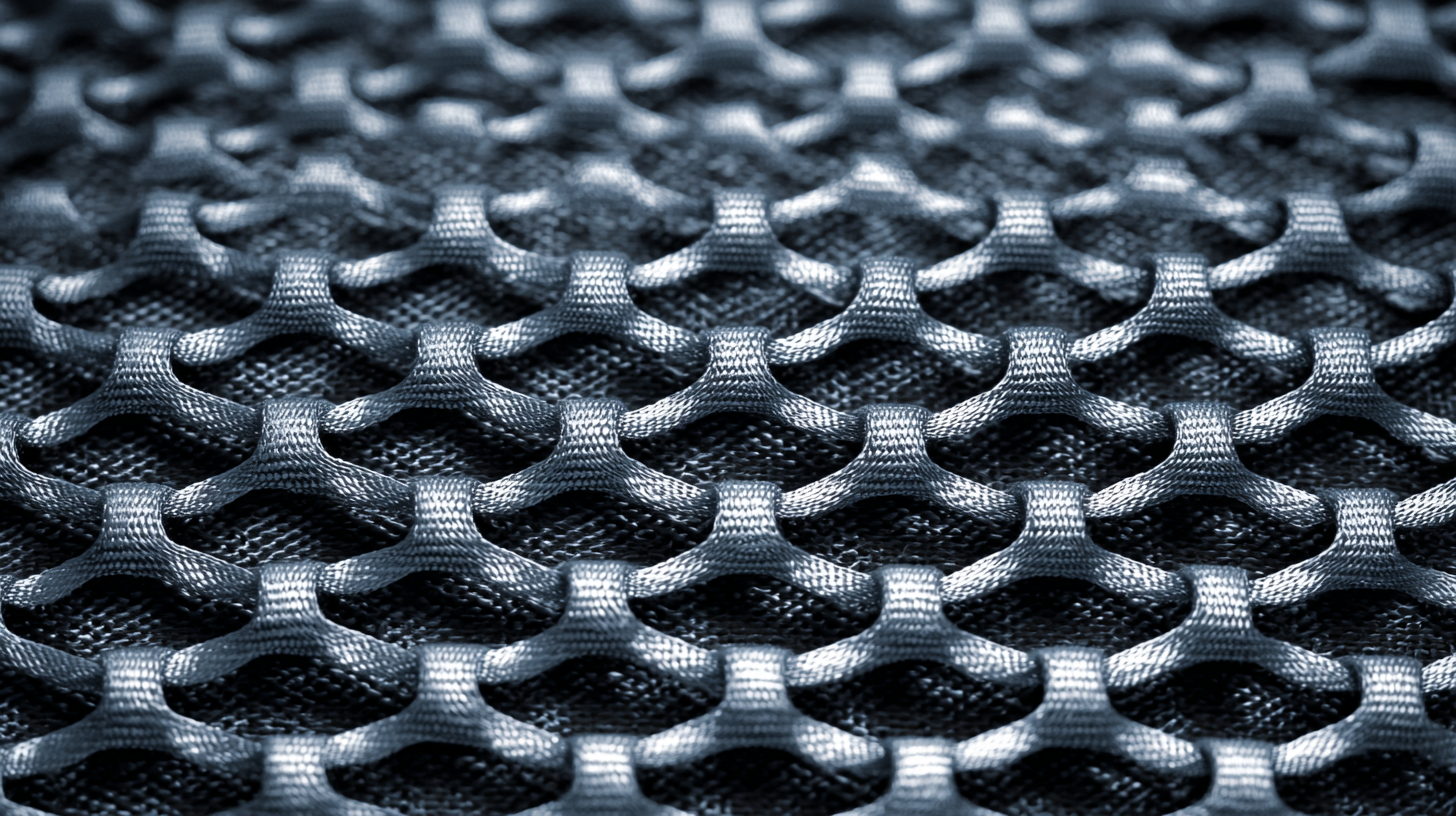

Another significant factor is the mesh's adaptability to various environmental conditions. Urethane screen mesh maintains its integrity under extreme temperatures and chemical exposure, outperforming traditional materials that may degrade quickly in similar settings. Additionally, its lightweight nature enhances ease of installation and maintenance, further elevating its appeal in modern applications. The combined benefits of enhanced durability and environmental adaptability position urethane screen mesh as a top contender in the filtration market, outperforming conventional alternatives across multiple key performance metrics.

Urethane screen mesh has emerged as a preferred choice in modern filtration solutions due to its remarkable durability and longevity. Unlike traditional materials, urethane exhibits exceptional resistance to wear and tear, ensuring that it can withstand harsh operating conditions. This resilience translates to longer operational lifespans, allowing industries to minimize replacement costs and reduce downtime associated with maintenance. The initial investment in urethane solutions pays off significantly over time, as they can endure heavy loads and chemical exposures without compromising their structural integrity.

**Tips:** When selecting urethane screen mesh for your filtration needs, consider the specific environmental conditions it will face. A thorough understanding of the factors such as temperature, chemical exposure, and physical stress will help you choose a urethane solution that maximizes longevity. Additionally, integrating regular inspection routines can further enhance the lifespan of the filtration system, allowing for early detection of wear and potential issues.

The economic advantage of urethane solutions is especially evident in industries that rely heavily on efficient filtration processes. By reducing the frequency of replacements and maintenance, businesses can allocate resources more effectively, thereby improving overall productivity. Urethane’s ability to maintain performance over time not only cuts costs but also enhances operational efficiency, embodying a smart choice for contemporary filtration challenges.

| Dimension | Urethane Screen Mesh | Traditional Mesh | Difference |

|---|---|---|---|

| Lifespan (years) | 10-15 | 2-5 | Higher durability |

| Weight (kg/m²) | 0.5 | 1.2 | Lighter weight |

| Cost per m² ($) | 20 | 15 | Longer lifecycle reduces overall cost |

| Resistance to Chemicals | Excellent | Moderate | Better chemical resistance |

| Maintenance Frequency (per year) | 1-2 | 4-6 | Lower maintenance needs |

Urethane screen mesh has emerged as a vital component in various filtration systems across multiple industries. Its flexibility, durability, and resistance to a wide range of chemicals make it ideal for applications in water treatment facilities, food processing, and pharmaceuticals. In water treatment, urethane mesh can efficiently filter out debris and contaminants, ensuring cleaner water for both consumption and environmental discharge. Likewise, in the food industry, its non-toxic properties meet health regulations while providing robust performance in separating solids from liquids.

Tip: When selecting urethane screen mesh for your filtration needs, consider the specific flow rates and particle sizes you aim to filter. This ensures optimal performance and longevity of the mesh.

In the pharmaceutical sector, urethane mesh plays a critical role in maintaining sterile environments. With its ability to withstand high temperatures and aggressive cleaning agents, it is perfect for use in filtration processes that demand high standards of hygiene. Industries involving hazardous materials also benefit from urethane's chemical resistance, providing a reliable barrier against harmful substances.

Tip: Regular maintenance and inspection of urethane filters can prolong their lifespan and enhance filtration efficiency, ultimately saving costs in replacement and repairs.

Urethane screen mesh is emerging as a crucial component in modern filtration solutions, particularly due to its positive environmental impact. Unlike traditional materials that can contribute to significant waste, urethane mesh is designed to be durable and long-lasting, reducing the need for frequent replacements. This longevity means less waste in landfills and a lower carbon footprint associated with manufacturing new mesh screens. By opting for urethane screen mesh, industries can actively participate in sustainable practices while optimizing their filtration processes.

Tips: When selecting urethane screen mesh for your filtration needs, consider opting for suppliers that emphasize eco-friendly manufacturing processes. Additionally, regular maintenance of the mesh can enhance its lifespan, allowing for extended use and further decreasing environmental impact.

Incorporating urethane screen mesh into filtration systems not only enhances efficiency but also aligns with growing sustainability goals in various sectors. Its ability to be reused and recycled positions it as a leading alternative in environmentally-conscious applications, paving the way for a more sustainable future in filtration technology.