No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

No. 14, Building 2, No. 367 Beijing Road, Chengdu Economic and Technological Development Zone (Longquanyi District)

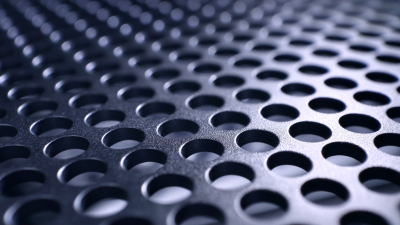

In today’s rapidly evolving industrial landscape, the quest for greater efficiency and productivity has led to the continual exploration of innovative technologies. One such advancement is the Pu Dehydrated Screen technology, which has emerged as a groundbreaking solution to traditional filtering and dehydration processes. This technology not only optimizes material handling but also significantly reduces operational costs, making it a vital component for industries aiming to enhance their production capabilities. By effectively removing moisture and impurities from various materials, the Pu Dehydrated Screen fosters improved product quality and consistency, thereby addressing critical challenges in sectors such as food processing, pharmaceuticals, and manufacturing. As we delve deeper into the benefits of Pu Dehydrated Screen technology, we will uncover its substantial impact on enhancing industrial efficiency and its potential to transform conventional practices into more streamlined and sustainable processes.

The adoption of PU dehydrated screen technology in industrial settings is revolutionizing how businesses approach efficiency and productivity. With increasing pressure to reduce operational costs while maintaining output quality, industries have found that PU screens enhance filtration processes significantly. According to a recent report by the Industrial Filtration Association, companies that implemented PU dehydrated screen technology reported an average efficiency improvement of 30%, leading to substantial savings in both time and resources.

One of the standout benefits of PU dehydrated screens is their durability and resistance to wear and tear, which allows for prolonged operational cycles without the need for frequent replacements. This not only cuts down on maintenance costs but also minimizes downtime, ensuring a smoother workflow. Additionally, reports indicate that these screens can achieve up to 85% solids recovery, making them particularly appealing in sectors such as mining and wastewater treatment.

Tips:

Pu dehydrated screen technology significantly enhances resource efficiency in industrial settings. By optimizing the filtration process, this technology reduces water consumption and energy expenditure while maximizing the recovery of valuable materials. As industries face increasing pressure to minimize waste and operate sustainably, employing Pu dehydrated screens allows for a more effective separation of solids from liquids. This leads to a streamlined process that not only conserves natural resources but also complies with environmental regulations, thereby promoting eco-friendly practices in various sectors.

In terms of cost savings, the implementation of Pu dehydrated screen technology can lead to substantial financial benefits. By reducing operational costs related to water and energy usage, businesses can redirect funds toward innovation and growth. Additionally, improved material recovery means less expenditure on raw materials, as more reusable resources are extracted from waste streams. Consequently, companies can achieve a quicker return on investment, positioning themselves competitively while contributing to overall sustainability in the industrial landscape.

The evolution of industrial filtration has led to the emergence of new technologies that promise enhanced efficiency and reliability. Traditional filtration methods, such as sand filters and membrane systems, often face challenges like clogging, high maintenance costs, and inconsistent output quality. These methods rely heavily on physical barriers to separate particulates, which can lead to inefficiencies over time as these barriers become saturated or damaged, requiring frequent cleaning or replacement. As a result, industries are increasingly seeking alternatives that can provide more robust and cost-effective solutions.

Pu dehydrated screen technology offers a promising alternative by utilizing a specialized material that enhances filtration performance. Unlike traditional methods, this technology allows for improved flow rates and reduces the frequency of maintenance interventions. The design of the Pu screens minimizes the risk of clogging, enabling a more consistent throughput while maintaining the quality of the filtered output.

Additionally, their lightweight and durable composition reduces operational costs, making them an attractive choice for industries looking to optimize their processes without compromising on performance. By integrating Pu dehydrated screen technology, companies can significantly streamline their filtration processes and achieve greater overall efficiency.

The implementation of Pu Dehydrated Screen Technology has proven to be a game-changer across several industries, enhancing efficiency and reducing operational costs. For instance, the mining sector has reported a 15% increase in resource recovery rates after employing this technology, significantly reducing waste and improving profitability. In the food processing industry, a dairy company that adopted Pu screens experienced a 20% decrease in moisture levels, which translated to extended shelf life and better quality of products. These case studies highlight the versatility and effectiveness of Pu technology in meeting specific industry demands.

Tip: When considering the adoption of new technologies, it’s essential to analyze existing case studies within your industry. Learning from the experiences of others can provide valuable insights and help mitigate implementation risks.

Moreover, the petrochemical industry has benefited from Pu Dehydrated Screens, achieving up to 30% enhanced separation efficiency. Reports indicate that companies utilizing this technology have minimized their energy consumption by 10%, contributing to sustainability goals. This remarkable efficiency not only translates to lower operational costs but also positions companies as environmentally responsible players in a competitive market.

Tip: Always measure the key performance indicators (KPIs) pre- and post-implementation to ensure that the benefits of new technology justify the investment.

The adoption of PU dehydrated screen technology has been steadily gaining traction across various industrial sectors, showcasing significant advancements in efficiency and productivity. Recent industry reports suggest that implementing PU dehydrated screens can improve material handling efficiency by up to 30%, a critical factor in sectors such as mining and waste management. This technology minimizes water usage during processing, aligning with the global push for sustainable practices while maintaining output quality.

Looking toward the future, innovations in PU dehydrated screen technology are expected to further revolutionize industrial applications. Emerging trends indicate an increasing integration of smart technologies, such as IoT sensors, which enable real-time monitoring of processing conditions. According to a market research report by Smith & Associates, the smart screening market is anticipated to grow by over 25% annually through 2028. This growth is driven by the need for greater operational transparency and the ability to preemptively address maintenance issues, thereby reducing downtime and enhancing overall productivity. As industries continue to seek out solutions that bolster operational efficiency, the evolution of PU dehydrated screen technology will undoubtedly play a pivotal role.

| Application Area | Efficiency Improvement (%) | Cost Reduction (%) | Technology Adoption Rate (%) | Future Trends |

|---|---|---|---|---|

| Food Processing | 20 | 15 | 35 | Increased automation |

| Mining Operations | 25 | 20 | 40 | Sustainability focus |

| Pharmaceuticals | 30 | 10 | 50 | Biomanufacturing integration |

| Textile Industry | 15 | 12 | 30 | Smart materials usage |

| Agriculture | 22 | 18 | 45 | Precision techniques |